Looks like Jim covered plunge rate which fusion don’t have the ability to adjust speed. This don’t cause me any issues but would be nice to have ability to adjust. Sorry I was trying to save you time with just using one software.

Don’t be sorry, I appreciate the effort. Because of you, I have something cooking over here and will post it in a few days.

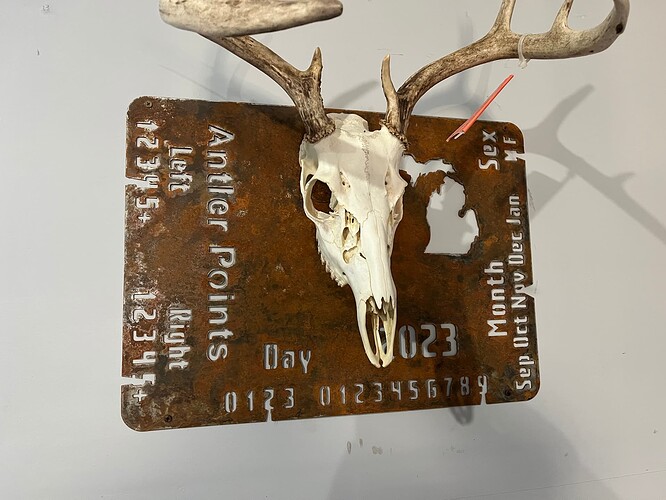

Posted for everyone to display those monster bucks we have in Michigan!

No monster buck this year for me. Pretty tough hunting this year. Way too warm!

You know the monster buck aren’t good eating. Sorry I had too . I prefer them like I do my beef a yearly.

It’s starting to get cold now so hopefully you get one before the season is over. Lots of nice ones running around state land in Gladwin County.

This buck used to range in our apple orchard surrounded by 30 acres of alfalfa. It got poached by a bow hunter. The fool entered it into the local big buck competition. Almost everyone in town had seen or had a picture of the the deer so allot of people reported it when it was displayed in the local sporting goods store that sponsored the competition. Also I think he posted pics online where others recognized the buck…. so he(poacher) was easy to catch.

Hanging out in back yard.

Took this pic from our bale wagon. He is standing at the edge of the orchard in the alfalfa.

What a rack! Am I allowed to say that?

I tried to research the UV paint that you used over the stained wood hand rail. I found that it was a more difficult task than I imagined.

Do you have the name of the product, by chance?

I’ll get it from my bro

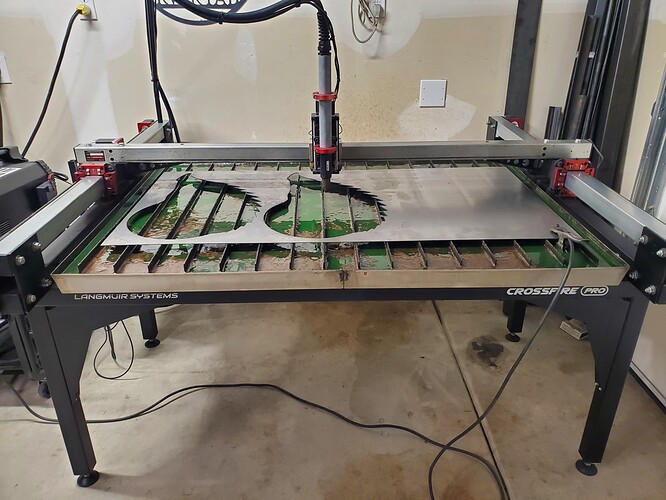

18ga - 18" x 19" - squares are .442" per side. 173 pierces! Tried to do this in Fusion, but it warped the sheet badly! SheetCAM with Limit Thermal Distortion set to 3" allowed this to happen.

RW45 @ 30A with Fine Cut. 130 ipm / .5s pierce. .150 / .060 pierce / cut heights.

2 down, 12 to go…

I cut these Aluminum running boards/steps out of some 8’’ tall C channel I got off a job. Just under 3/8’’ thick, then welded the steps on. Its just a plow truck that has lots of Bondo on it. looks good from 50’. I clamped a 1"x4" board to my pro table so I could index the channel,

its about 7’ long overall. I cut Active and Contracting separate. It was suggested to back light it but I thought that might be a little to much ![]() My wife thinks its a little to much now. but she wont ride in it anyway.

My wife thinks its a little to much now. but she wont ride in it anyway.

Totally!!!

You’ll have to explain having your business sign on work truck is tax write off and I bet they even have one for lighted signs these days. Hopefully you got good tax guy. Good luck on new lighted sign!

Friday off built an air dryer. I cant believe how much moisture is produced. Consumables should be lasting longer.

Why did it slow down so much?

I shot the video at 240fps for super slow motion. I slowed it down to show plasma sparks detail.