I’ve asked the Etsy vendor if I can post them here.

Thank you sir! learning a lot still very much a rookie when it comes to fabrication. Would love to help.

I live in the south though lol

Made this for a buddy of mine that is a big Michigan fan,

even named his dog Big house.

Would have cut this out of steel but font was to detailed so I cut it out of MDF on a laser.

Can’t remember if you have posted in the past or not. What is the drivetrain going to be?

2.9 ford v-6.5 speed manual trans, manual transfer case, 44 dana high pinon front axle out of a 1975 ford f150. engine has 4-barrel Offenhauser intake, crane camshaft, I am building headers for it.

It’s 25 minutes long if you have time to kill otherwise you can skip to the last minute. Made these for family who just finished building a house on Green Bay. Still working on the deck…

Looks great. Not sure they needed the supports - standard looking cantilever that wouldn’t require additional support.

But great excuse for the decorative steel work. ![]()

That’s not standard, those are just hung with joist hangers. You would need to run those joist back into the house framing for any strength.

I take it that little deck/patio was after thought

Ah. I thought they had just put that leger board on the end of the deck framing and added the cantilever instead of running the joists out from the house or even adding the new ones as sleepers to the existing structure. It didn’t look like it was big enough for an add-on deck.

I still like the pelicans - they looked really good with the water splashing creating depth and definition to the design ![]()

Unfortunately it’s not cantilevered, it should have been though. When the house was framed that balcony appears to have been a complete afterthought despite the fact that they framed in a double door opening on an exterior 2nd floor wall…We used 10 tension anchors to hold the joists tight to the house because the struts will cause some of the downward weight of the balcony to become lateral force pulling the balcony away from the house. We’ll see how this holds up, it’s definitely probably most likely not code. The base of the struts at the house are lag bolted into 4 2x6’s sistered together as a column so there is plenty of strength at that joint.

I’ve been there before.

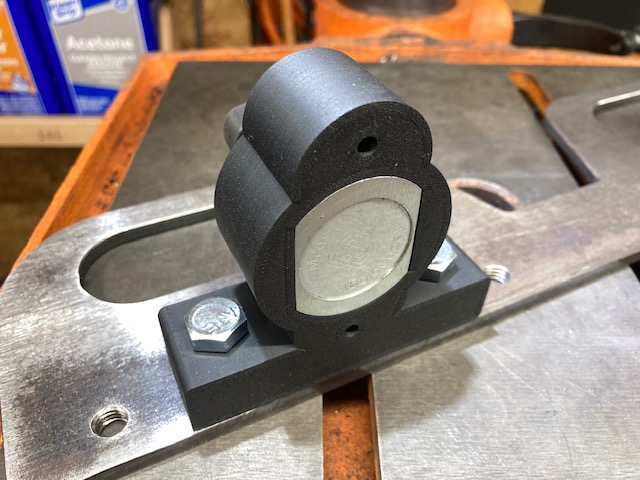

Instead of buying a drill press fence, I wanted to make one to give me some extra CAD time for plasma and 3D printing. I already had the magnet mounts from woodworking jigs. They just press fit in which is good since the brass heat inserts didn’t work out but are hidden inside. Design inspiration from the one by Magswitch.

16" long, 1/4" steel, PLA for the mag mounts, 3/8" threaded holes.

@john_s Great idea, can you post the Fusion or the STL file?

I have added it to Fireshare but the 3D print STL file did not attach. Assuming I need to Zip that file but how do I edit a Fireshare post?

Edit: I absolutely HATE Fireshare, what an awful platform. No way to edit once posted that I can see. Summary is a full run on text block with no formatting preserved, paragraphs would be nice or line breaks. I deleted the Fireshare project in hopes of updating a new one but that failed. It also removed the files on the second try. Unless someone can help I am walking away for now.

I give up on Fireshare, so here are the files for the magnetic drill press fence.

Fence DXF stats: 16" long, 1/4" thick steel, plasma holes are intentionally undersized, you need to drill them with 5/16" bit and thread with a 3/8"-16 tap.

Requires 2 Magswitch 150 switchable magnets: https://www.amazon.com/Magswitch-MagJig-150-Set-2/dp/B01B59KW6Q/ref=sr_1_4?crid=2O28Q0M63X8D8&keywords=magswitch+150&qid=1687185590&sprefix=magswitch+150%2Caps%2C109&sr=8-4

STL included for 3D printing the mag mounts. Magnets are a perfect press fit for me (CC3D Matte Black PLA on Bambu Lab X1C, your setup may alter the print accuracy so size up a fraction of a percent in X and Y axes only if necessary.)

Need 2x 3/8"-16 hex bolts with 1 inch thread. Bolts may need to be ground down and shortened the smallest amount if they extend further out the front holes.

DXF for plasma

drill press fence v1.zip (9.7 KB)

STL for 3D prints

magfence mounts centered.zip (5.5 MB)

For reference to post above:

What size is that?

Do you mind telling what it runs you for p/c

The steel is 2”x2” sq. What does p/c mean?