I agree but snowblind is a textured powder that requires a thick coat. I don’t think it will texture with multiple coats

I spray satin black as first coat under wrinkle black and it turns out as good or better as two coats of wrinkle.

Did you weld that on a positioner??

I welded the top bracket to the frame. Its obviously a kicker so the small battery is just for the ignition system.

In the new tiny houses, that would be considered the guest bedroom space. Nice use of storage.

I built this press brake from stuff that I had in the shop. The base plate and bolt plates for the blade were cut from 3/16" and the blade was cut from 1/4". I built it with a bolt on blade, so that I can cut smaller fingers to bolt on as needed in the future.

Guitar dude is awesome!

i see, nice work!

Yes, I did weld it with my positoner.

Looks really good!

How did you fasten the layers together?

Good job! That looks awesome!

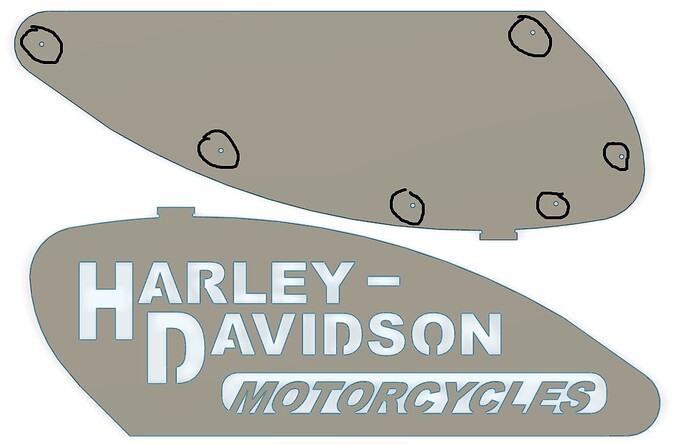

I really like the colors you used, perhaps that was dictated by the customer or the logo.

I also had the same question that @SWomack asked about how you attached it together and how will you be hanging it?

Lay the layers where you want them flat and trace the smaller letters to the layer below. Then mark and drill holes in the lower layer then lay them back on top of each other and line them up. Trace the drilled holes to the top layer and weld a bolt to the back of the top layer where the holes are marked. Then mate the bolts on the top later with the holes on the lower layer and bolt up. It’s kind of complicated to explain but it’s just drilling and tracing then weld bolts and Mate. I just welded all thread stand offs to the back to mount it. Let me know if this makes any sense!!

Yes sounds better to me than having holes in the top piece and grinding off a bolt head.

Yeah i built this with 16g I would recommend using a bit thicker material on the top layer to avoid penetration marks, or really take your time blending them off. powdercoat can really showcase imperfections. i am a process pipe welder/fitter so i have a lot of pertinent skills, but the thinner gauge steel takes some getting used to. it really is a lot of fun to do these projects.

yeah the colors were from the company logo, quite a satisfying combo. i answered the layering question above. cheers!

i do a lot of layered signs and i have found marking your holes in the design makes it easy when you putting them together. i started out welding myself but as you said you can see the marks on the face of them sign if you not careful. Let me know if you have any questions. i’m happy to help. i do this for fun not business.