Small tool holder I made

Made these custom mountain bike mounts for my buddies Sprinter Van company. They attach to L-track and then a strap goes through the slots making it all extremely tight. Made out of 1/8” material then welded up the bend lines once done.

here is some custom art I did on request…

the large heron is 4’ tall…the other one is 3’ tall

the main body and legs are 11gauge steelllland I placed an extra layer on 11gauge steeel on each side of the legs…gives a little 3D look and gives the bird strength from bending

Week 3 of owning my crossfire. Figured I’d do something for the local hardware store and give myself some advertisement. Table has paid for itself already

Ah, very crafty! Nice sign!

Looks pretty darn great!

now that’s funny! lol!

Do I detect some timely photoshop work here?

Had to get in while I still can… plus showing off my latest creation.

Indeed! Nice work!

Indeed! Nice work!

I see the clevis pins, does the whole thing tear down to a flat?

Not totally flat since the top pan is bent but the sides are almost flat other than having a top lip for the pan to sit on.

I like the way you did the highlights on the hammer.

Are you a graphics designer as well as a CNC cutter?

Nothing major on my cross fire pro yet ! Still running the machine with THC off due to faulty parts… seeing everyone’s art makes me very keen to do some!! All the art guru’s,what software are you liking to design in ?

No sir. This is a file I had in a file pack. I only did slight modifications to it

@Smurfos that’s a bad ass fire pit

Cut lots of large box tube end plates, hang plates, hooks, gussets, etc. Cut some riser plates for when I install the XL kit parts.

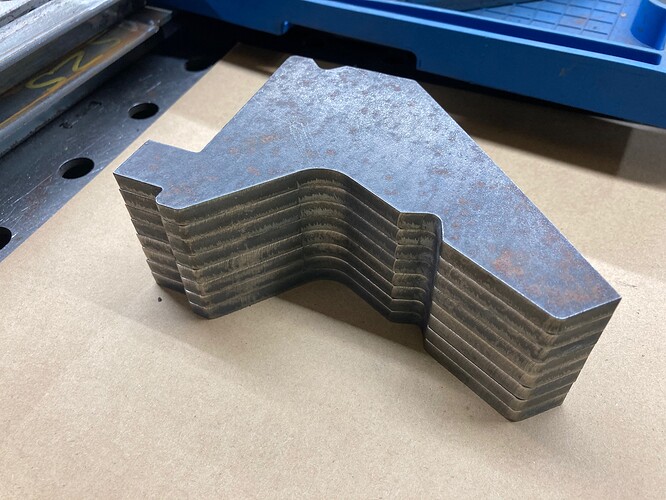

Needed some gooseneck dies for the Swag Offroad heavy duty finger press brake, but their versions are short, so designed larger ones and hope to try them out soon. Just 1/4" plate. I’ll weld them in groups for different widths or 1", 2" etc.

I’ve made a few dozen capture nut mounts from 1/4". Weld them to 3/8" nuts to mount hockey pucks as feet for different projects, a bench grinder stand, a couple radiant heater stands for a restaurant. Still trying to improve my tig welding.

Bought some rollers from McMaster Carr and designed an adjustable roller guide for cutting long tubing and angle iron. First of several of these I am making.

All on Crossfire 2x2, Primeweld Cut60, ViaCAD 2D / Sheetcam / Mach3

The cuts look pretty good on the 1/4" finger dies. What Plasma Cutter do you have?