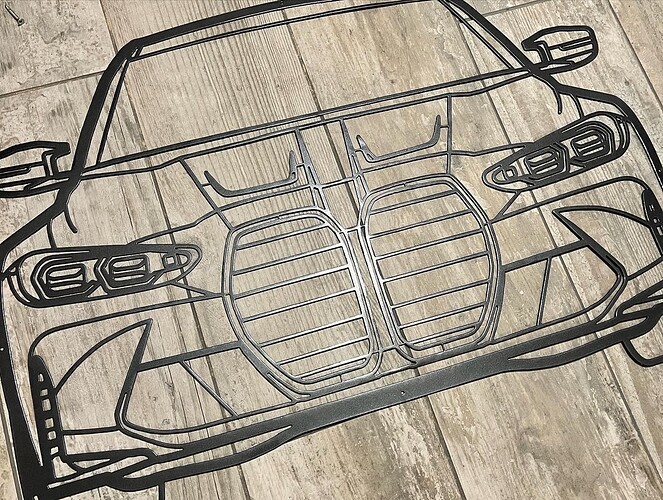

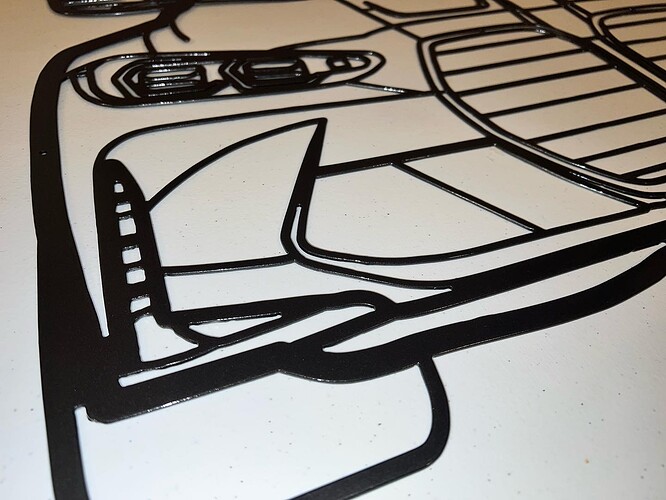

Great job! What system did you use? I guess that would take at least a Pro to fit the 3 foot height.

yes, a pro. The pattern had trees top-to-bottom at about the right spots for the indexing, tho one section ended up at 33.8" so I scaled that one down to 32.8", just barely fit. A total of 3700 seconds of machine run time, tho only around 25 minutes of torch burn time, and around 500 pierces. I put new consumables on before doing this one. I was a touch off on a couple of the indexes, but with the top-to-bottom trees it doesn’t show.

How did you index? Scribe the workpiece or something else?

I really like this piece, where is it going?

Thanks! It was a bit of a challenge.

I split the dxf into 4 layers at top-to-bottom tree boundaries, then fought sliding the sheet with the crane helping to roll the pro under (much cussing!) Then I pretty much eye-balled the alignment (hence the bit of error) With the sections split along the trunks of trees the alignment wasn’t critical. The sheet is 11 ga cold rolled, which was heavy enough to be a bit of a pain.

Were I to do it again I’d want an edge alignment tool of some sort. Since I did cuts along the outside edge of the piece I had a decent spot to line up the indexing.

The original file was a free one found on the internets, here is the slightly touched up version:

ballusterSceneIndexed.dxf (2.6 MB)

This piece is going to my cabin in southern Colorado (west side of the San Luis valley). There is a loft with just a railing and no balusters, so this will fill in between the railing and the floor of the loft ( so that kiddies or dunkies don’t fall off ). I’ll post another pic when I get it installed (in a few weeks).

Sweet! That’s an excellent place for it!

Check out adding a simple laser diode alignment guide. In my case (with an OG Crossfire), an angle iron clamped along the Y=0.5" line of the slats, was more than adequate for aligning along X axis, and the laser aligner got me well within less than 1/32" on each segment. I’ve made 72" indexed cuts on that setup with good accuracy. (Centering on the tree trunks is ideal ![]()

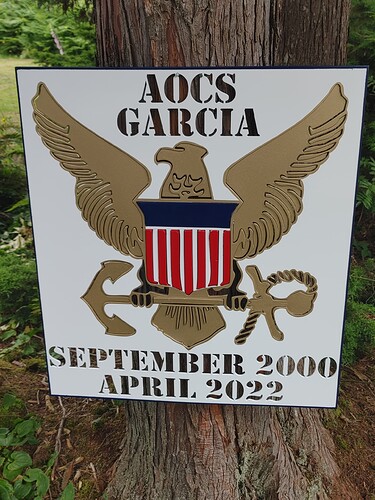

Because size matters

mag grounding clamps are nice if you only cut carbon steel…

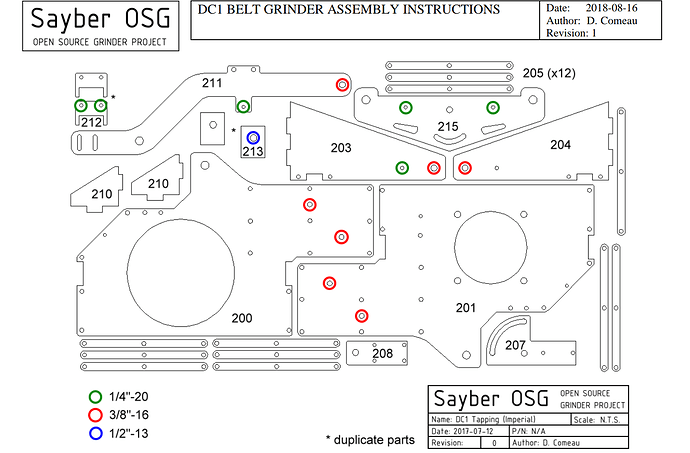

would you share the cad files for that belt grinder?

I found this yesterday,

Sort of like this:

I’m still working on it. Doing a few tweeks and changes. Not sure if I’m going to sell kits, or just give out the file. Probably give it out, and if I do I’ll post it on Fireshare as dxf files. If I decide to do kits, I’ll make up a simpler version and post that.

I have a few other grinder plans i have found on the interwebs, when i actually decide to make one i’m probably going to take the best features of all of them and come up with my own design. so when you do finalize your design, i’d like a copy. i’m not apposed to compensating you for your time. trades, cash, whatever…

No problem, happy to share ideas. I’ll let you know. I’m puzzling out where the idler wheel will go best. Waiting on some new nozzles for my plasma torch. Cutting 1/4 and 1/2" plate tends to eat them up.

This is a pretty decent open source grinder project. Worth taking a quick look at.

thats nice i need to do something like that for the home shop

thanks for putting this on here!