Tks for fast reply, you’ve really helped me from the begining of my cnc journey.

You’re very welcome. I wish you the best of luck in your venture.

That is a stout machine

Did this for my good friend and business partner. Probably the most time Ive put into design etc on the metal portion. Colored with just a torch. I found using map gas gave me the best coloring after practicing on scrap. Wood was from a house I tore down that was originally milled from red cedar taken from Prince of Whales Island here in Alaska. Cool project and get to see it every time I go down to my boat that is moored on his dock!!

Nice sign and great view!

Tough to turn that cart around if it gets stuck though ![]()

It’s a one-way trip…

My wife wanted a serving counter for our outdoor dining area. I through together one in about 15 hours, complete with barn wood siding. 2 rolling doors, perf metal top. Used my XPro to cut roller wheel hole, ‘drill’ the flat bar for barn wood attachment and tubing threaded tube ends for leveling feet.

NIce build! Hoping to do something similar…

quick question witch im sure you have been asked 2 million times where did you get that ground magnet set up

Arc Zone I use a 300 amp version. They have smaller sizes. $83.00

Here’s a sign i did recently, its powdercoated in Empire Copper Vein from Prismatic, overall size is 30" x 8.75"

I like that. Looks like some fine detail in the corkscrew (thin). What plasma equipment & tips did you use?

its a RW45 with a PTM60 machine torch with 40A shielded consumables, its definitely a delicate portion of the sign, nerve wracking part of the cut.

Very nice job on the sign, I like it.

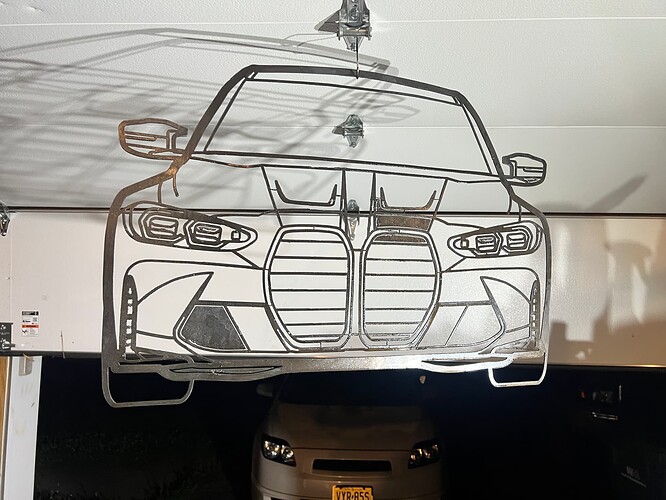

Cut this tonight, came out good for my first cut of it, all drawn by myself. Biggest and prob most detailed cut I’ve ever done. It’s 30”x21”

LOVE LOVE LOVE it!!!