Good thinking. Was thinking if it was sold concrete then that was some thick gauge steel

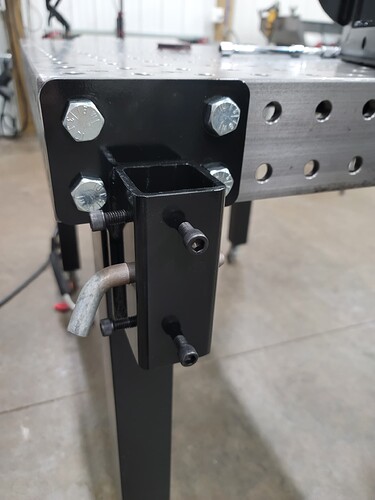

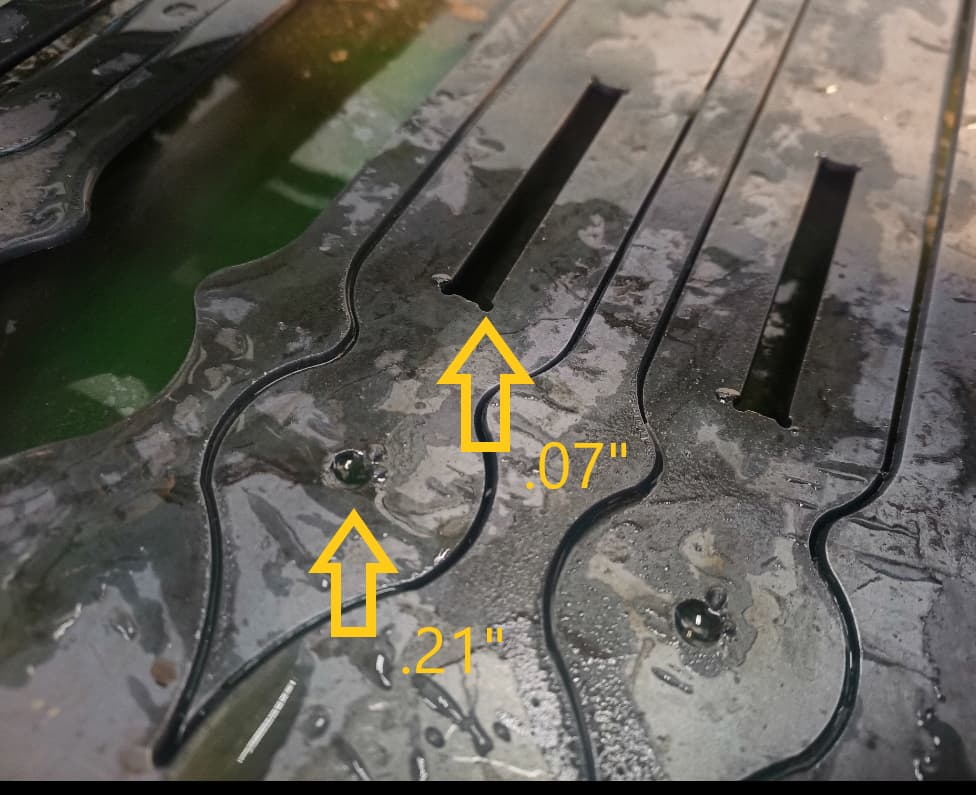

Bessy vise mount.1/4 plate cut on my crossfire pro.I wanted to mount it to the table but didn’t want to take away from the top surface and want ed to be able to remove it incase.

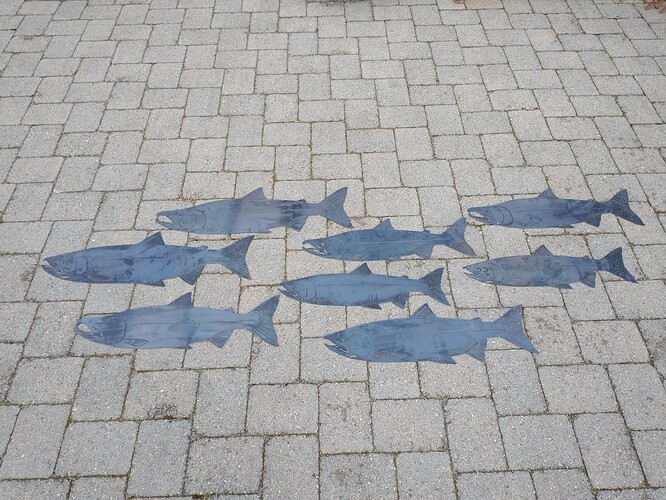

Got asked by our local museum to do some spawning Chum salmon for a display. Work in progress but I’m really happy with how they’re turning out. 16 Ga hot rolled.

Going to leave the mill scale on and just grind them a bit for some contrast. Looking at coating them with boiled linseed oil. I’ve used that on some of my forged projects.

@Heath

that is a simply marvelous idea…simply great…

you can interchange bench grinder…vise…articulating arm for jigs…

great work…gonna use the same idea…when i get my shop and table set up

that looks awesome and such a simple design. are you gonna put it up on fileshare?

Your cheating  I use to make them by hand

I use to make them by hand

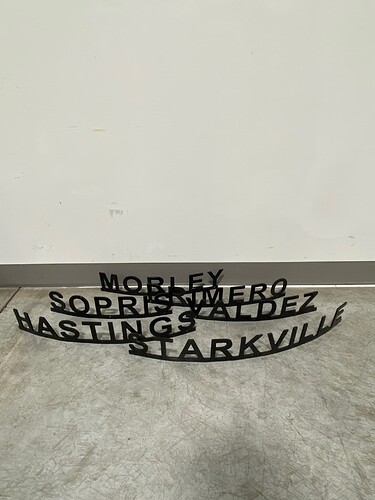

The lettering is a nice touch.

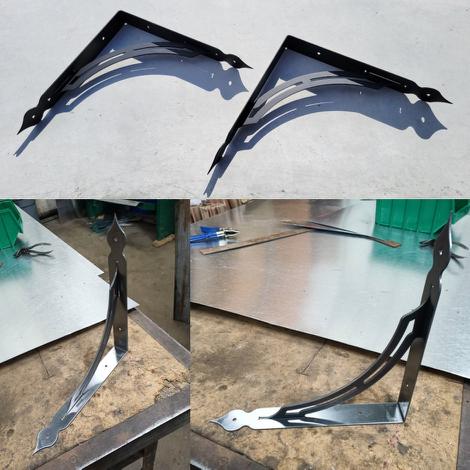

Nice brackets! Where’d you buy them?

Nice dogbones on the corners of the slots. Is that a Fusion option?

Definitely not the cheap way to go.

there is some add on’s I dont use, I draw them into the sketches and my them constrained so if I make changes the holes stick the right places.

Sheetcam has an option to overcut inside corners like that. The only problem is that it applies it to all of the inside corners unless you do a separate operation for only the contours you want overcut.

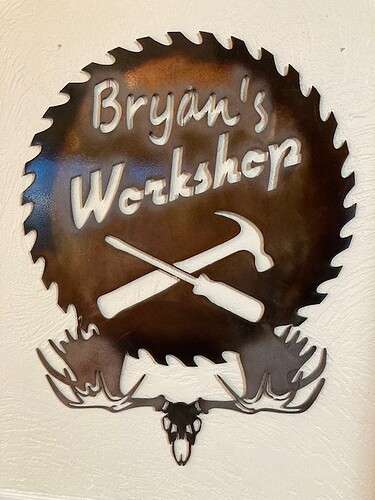

Workshop sign for my buddy I moose hunt with. Did a little sandblast affect on a few areas after patina color.