Finally able to get this done… came out nice!

My buddy is making Mexican Train game boards with his CNC and wanted me to do up some game tokens for him so I gave it a try. My first time doing something small (1 inch) and I was pleasantly surprised. Not sure I’d want to go into production though . They’re a PITA to finish. ![]()

They look super though ![]() You may get more requests once your friend gets these.

You may get more requests once your friend gets these.

Thanks a bunch! But I’ve gotten pretty good at saying no since I retired

Okay I might do a few more…

Nice cart!

An enclosure we fabricate for a local man.

He makes audio effects pedals and there will be some circuitry, switches and knobs to be mounted in to and the through this enclosure.

We just recently got set up to do some powder coating so some of our first attempts.

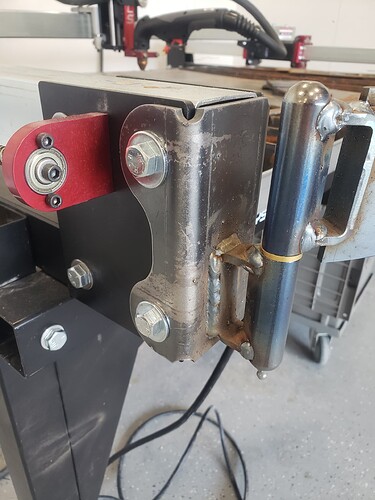

I can’t remember if I saw inspiration for this this here or on YouTube but this is a shelf built for the Hypertherm to mount it under the XR. 11ga with some 1.5” 11ga flat welded below for support. It was the first real project for the XR and couldn’t be happier.

Can I use this last picture to show people what NOT to do when setting up their CNC table.

I got your PM .

You are right I should have pointed out the things that were or should not have been done in your picture.

The plasma cutter should not be under the table. 240 volts and a CNC table full of water is not a good thing.

Also if you look the torch cable has a loop in it, the control box cable is coiled and the work cable is coiled. These will create a magnetic field when power goes through them and may or can cause interference with electrics.

Another Mach3 control system that I have. Serviced and re-calibrated my CNC Mini-Mill today. Here’s the second pass making a bolt-circle in a test coupon.

Bah! I’m waiting for the CNC conversion of the big-ass mill! 5 axis, at least!

Did a cool sign for one of my customers for his pizza place. Took his logo and made it metal worthy. Pretty excited with how it came out.

Wow! damned cool!