This is my first paid job. Turned out real nice and I’m proud of it. Customer of mine did the wood podium and I did the badge.

Wow! that is AWESOME! …congratulations!

Not Plasma related but I made this from a 6061 billet, for one of my sons, He’s a nerd (Phd in Molecular Biology, Cornell), his Coffee machine would put the average chemistry lab setup to shame. Done with my lathe, mill and 3W laser Ultrasonic Engraving Process, which I developed last year and currently seeking a patent on.

Machining down to a thin wall thickness without trashing the job, proved fairly challenging, but a few shots of bourbon later, proved very rewarding indeed. (That’s a human hair above the engraved text for size reference)

nice work…but if that is a “curly” hair do not serve me coffee!!!

Hahaha, not a curly, not a curly!!

I am not knocking your work…you are a mad scientist for sure…and good luck with your patent…sell the use of the patent for $0.01 per logo engraved…adds up quickly…

as for the coffee pod…this might have been easier…

hahahaha

He probably has to wait 3 years for the slow boat from Florida and then there’s the customs…

Of course, you don’t know about that kind of stuff, do ya? ![]()

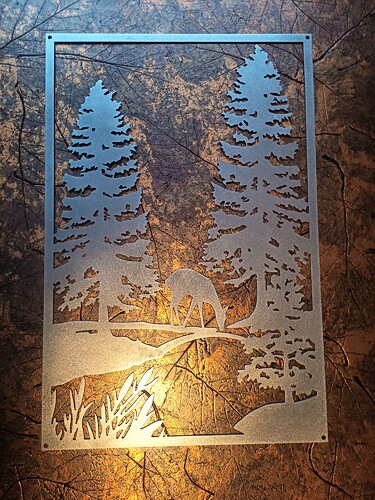

Prepped a couple little things for finish today.

The panel is 21x 14

The bee is 8 inches across

I used standard 45 amp hypertherm consumables unshielded at 45 amps at 250 in per minute.

Nice work, TW! I’m sure your recipients will love them!

Happy Holidays!

Thanks a lot .

Merry Christmas and happy holidays to you too

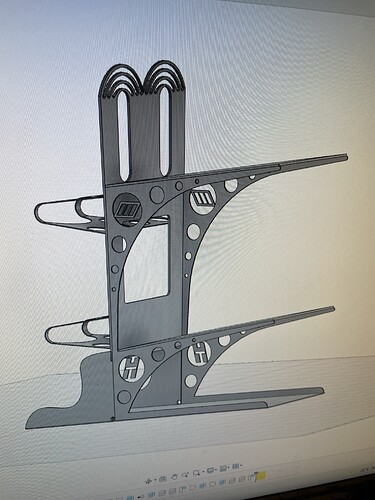

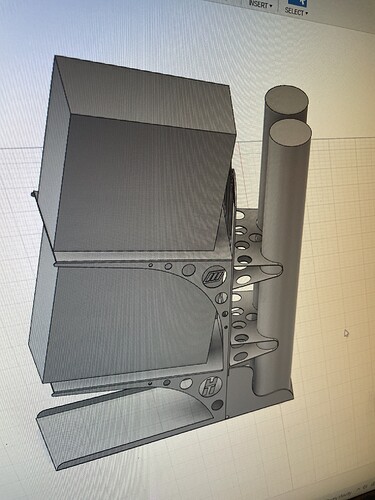

I know, it’s just drawn up, but it’ll be my first big project on the Crossfire with the XL kit I finally got last week! I’ve been lazy using cheap HF carts, but space is getting tight in the garage so time to make a single weld cart for the welder and cutter. It’s only 16” wide, and hopefully on the thin side of 20+ Inches once I get the cables hung on the side. Fully designed to be cut on the crossfireXL, in various pieces, so crossing my fingers it all works! I’ll generate toolpaths tomorrow and see if the wife will give me a Christmas present by letting me do some cutting in the next couple days instead of the Christmas alternatives ![]()

I really appreciate all the lurking I’ve been able to do on the forum here, so thank you and Merry Christmas!

Looks like you have Fusion figured out. Please post pictures of your project when you’re done.

Excellent.

fantastic…great contrast there…what guage?

Sides, back, and rod/tank holder will be 1/8”

Bottom shelf 3/8”

Mid and top shelf waffling between 1/4” and 3/8” since I have both on hand.

I don’t think I’ll need any additional support once I get it welded up but there is room to add it, if needed.

This one was fun. Made a trenching bucket for my HF digger. 3 cut files for 3 different thicknesses of material. Drawings took a bit and some trial and error to get all the geometry correct but very happy with the finished product. I have about 600ft of trench to dig in the spring.

I’m fairly new to the plasma table world and it’s hard to describe how much this has changed the game for me. Probably took me 1/4 the time or less than without the pro table.

This is 14ga I burned the first one from 16ga but the drawing was way too detailed and the burn out didn’t turn out nice so I fixed some of the drawing b

Merry Christmas all!

Seriously?! This is the kind of thing that makes me want something like the GF digger and make a trencher for it. Not something I really need but it’s now on the “I want this” list. This forum is bad for controlling diversions down rabbit holes

ya its projects like this that keep me from actually making money in my shop. Its like being a heroine dealer and an addict. All my steel, supplies, and time just keep getting used up on my own projects but I love doing them.

what is your method for getting that uniform brushed finish on the bee?