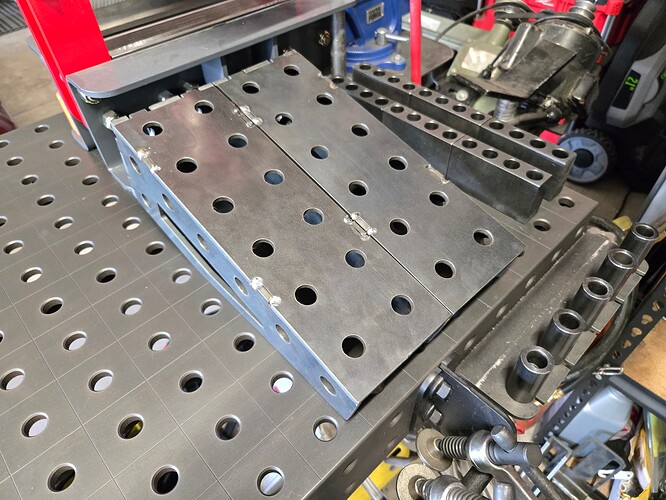

Made myself a second table extension, just need my ball lock pins to arrive and I can start using them right away

Nice work.

As for the forklift issue - could have rented a tele-handler/rough terrian forklift. Lower height, does not rely on a mast to raise the object. plus the telescoping gives you the option to extend out and place where you can’t drive.

If / when I leave my current place of employment, that is what I will have to get to unload my mobile fabshop from the company trailer into my garage.

Never used one before, but looking it up I can see how that would’ve been useful (and more expensive lol).

I’m only forklift certified, so I would’ve only looked at renting one of those. The time window would’ve made it tricky as I don’t know how accurate Sunbelt Rentals is with filling the time slot?

Are they vastly different compared to using a forklift?

Don’t know crap about milling, but is it possibly to mill out 4140 tool steel on the MR1?

I’ll watch that video after my Zoom meeting!

I ask because I’ll need to find someone to mill out a punch for me for my press brake. Current one is made of 4140 tool steel so I figured I’d go with something similar.

Telehandler has a larger turning radius than a forklift.

Forklift has larger ceiling height requirement.

For a street, to uphill driveway, and 2 car garage with a 7ft tall door, I’d take the Telehandler and some skates if I had to maneuver the object around once inside if the clearance was tight.

Maybe I’ll look into renting one if I opt to buy a laser table down the road, or get something like a Fastcut or something different.

Yea that seems like a good upgrade. I have some of my larger parts that dont nest well on 2x4. End up with odd space left over that I can fill with my smaller brackets, so now I end up with a huge pile of my small brackets. More than I need. Between that and the increased rapid speed my efficiency would go way up.

This kinda snowballed pretty fast. I have been painting everything with an hvlp sprayer but I think I’m going to farm that all out to a powder coater. Looked into doing it myself but I hate finish work. Plus thats another 3-5k investment with a booth and oven. I was getting parts lasered and finishing them but then I quickly turned into a painter not a fabricator.

some more footage of the 3D machining of MagnaCut on the MR-1

Sorry guys I just realized this is the Crossfire Projects thread. lol

Paint, powdercoat, that’s stuff I’ll never touch. The hell with that.

Not going to ruin what are structurally sound welds, precisely cut parts, and perfectly square assemblies for a shit rattle can job or powder coating with no experience ![]()

Stool I made for a repeat customer got powder coated last week, forgot to add a picture. He said the pictures don’t do it justice and I believe it.

Metallic red or something like that.

Pretty sure my 24” X axis gantry is bent. Was noticing some inconsistent bent parts. They weren’t hitting the backgauge correctly. My table is heavily molded, but this is on the factory langmuir X axis. One side has a slight convex and the other has a concave bend to it across ~20”. Gonna have to put a straight edge on it tomorrow and see what’s up. Anyone think of anything else that could be causing this?

A friend was cleaning out his garage and gave me his vintage Onkyo TX-2000 receiver. Perfect shop amp for my estate sale Klipsch Forte speakers. Added an old Belkin bluetooth receiver and finally have some great shop sound, I’m in $12.50.

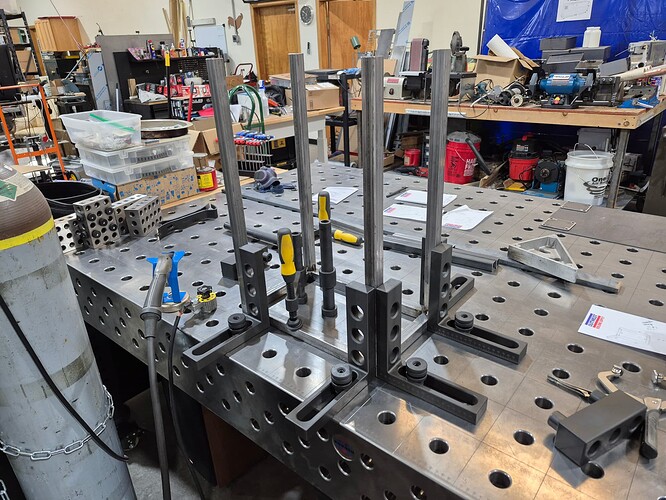

We want everything on wheels in the shop (except the mill and the lathe). Fixtured up a little bench grinder stand with Vevor leveling casters.

Nice little project this afternoon while these filled the airwaves.

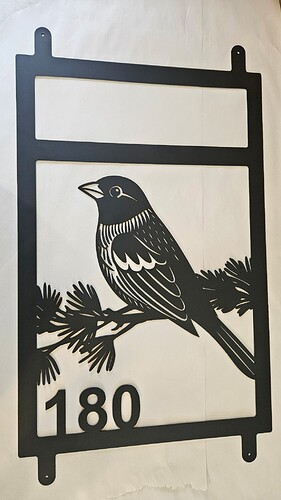

A couple projects that were cut on the weekend and finish today.

The one bird sign is 3 ft tall plus the tubs. And the owl the wall hanger is probably 22 in tall.

The little puzzle piece was actually hard to cut that thin in 3/8

I sent my shop Amp in for a full chassis rebuild a few months ago. i’ll be into it close to $1000 including the original cost. but its worth 1.5x to 2x that… you cant beat less than 0.1% THD at 350W RMS and 750W peak per channel.

impressive!