I’m jealous. Shame that protecting your lungs has to cost so frickin much.

The price is based on what a new set of lungs run! ![]()

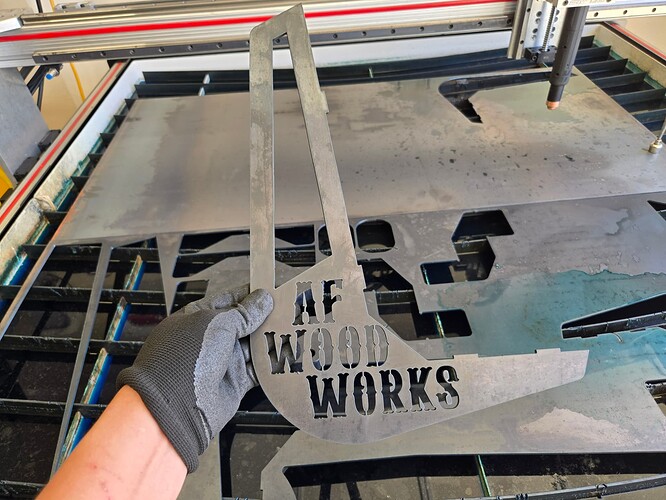

Fun gate for a customer. A few touch ups to the file for the next one. but in all pretty happy with the result.

Very Nice.

what size is it?

did you do it it in one run?

did one tip do the entire piece?

Yeah. The tips last quite a while. I did it in one shot. The gate is 70 tall 40 wide.

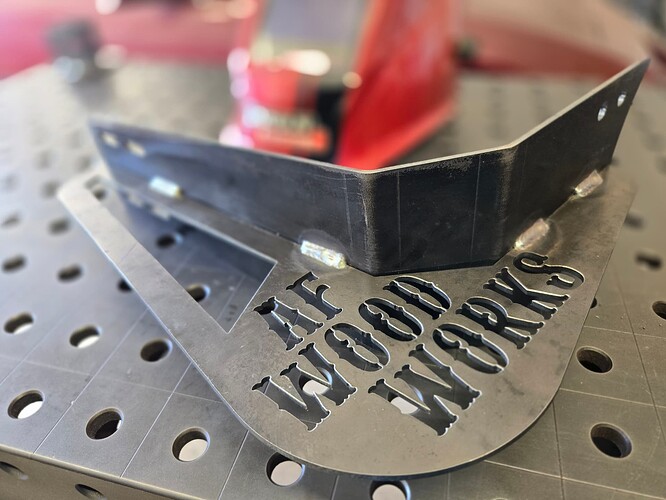

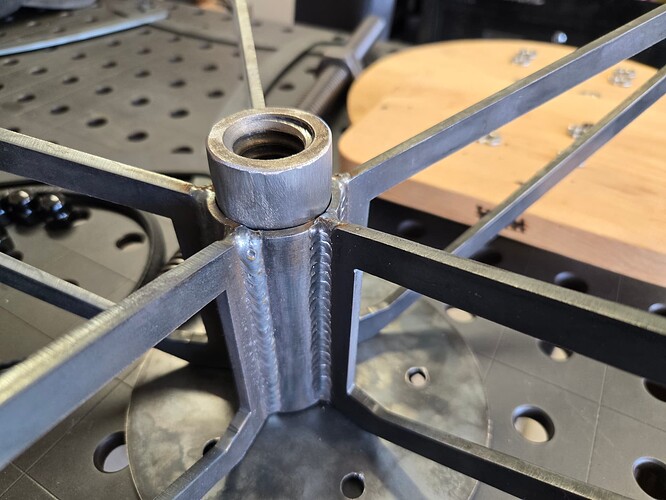

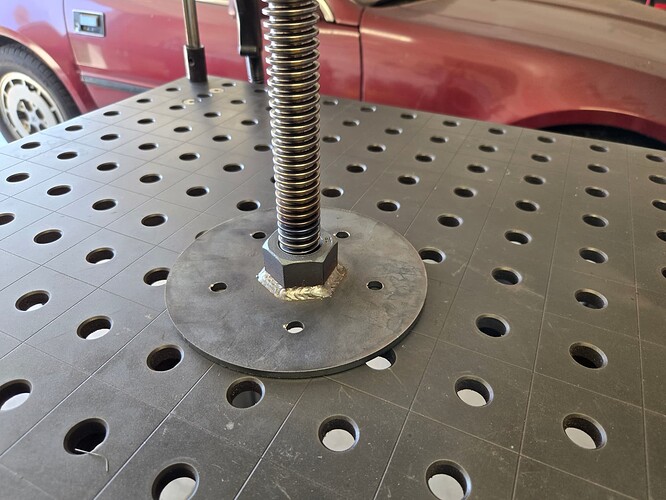

Local customer wanted a stool like mine

Now just need the casters to arrive sometime next week; I’ll be able to confirm using some leg braces I cut out.

Also the leather needs to be picked out as well as the whole thing being painted.

Otherwise, she’s done.

How is your new table working for you?

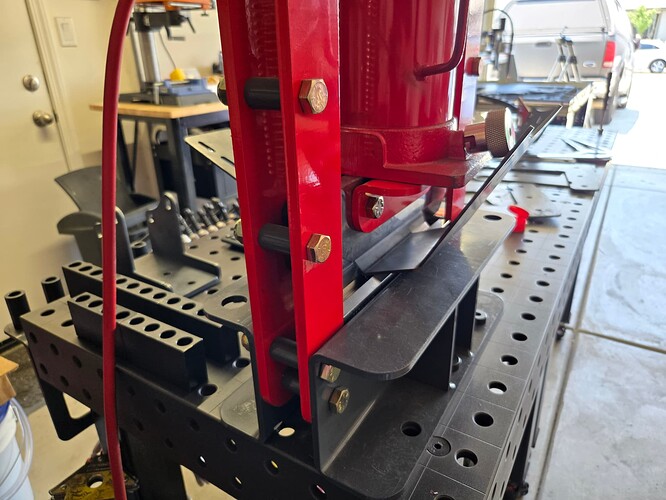

Here’s your suggestion. A strap clamp around the front to hold that big chunk of the tip or, use some Loctite or high-end super glue and glue it down.

I thought about gluing them to some painters tape. I’ve done that before.

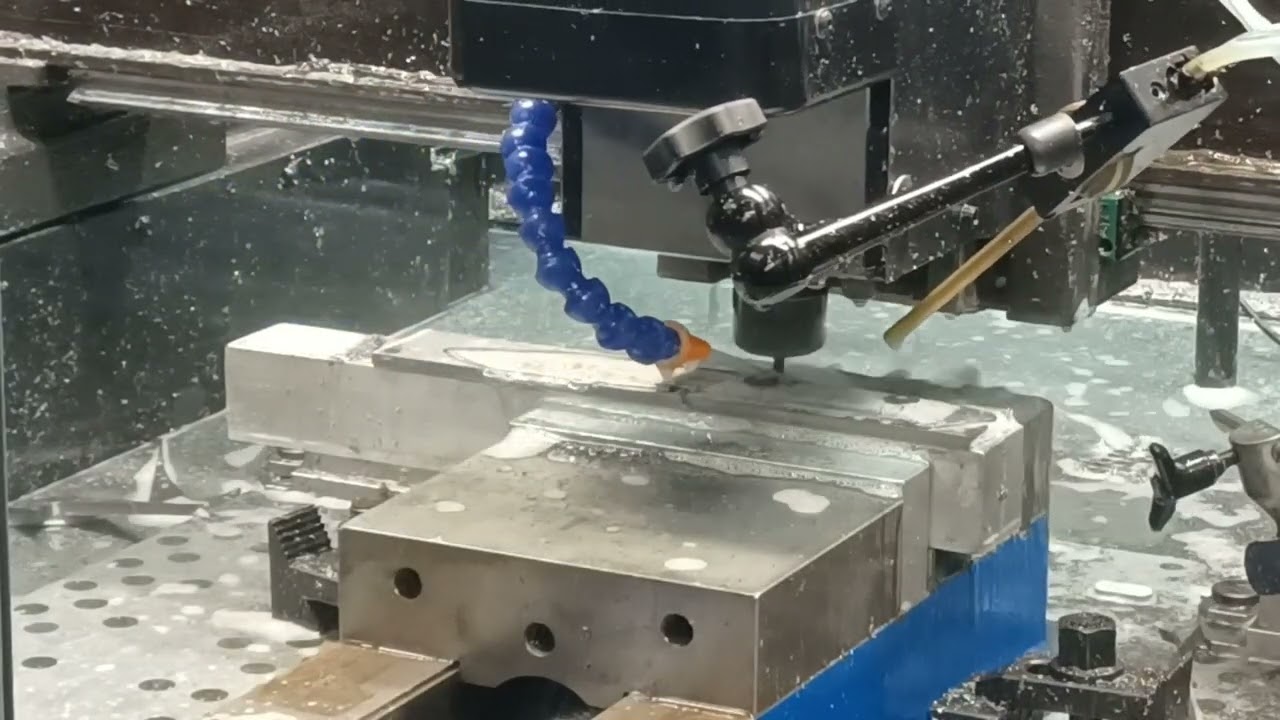

I might also try to use tabs and put an M0 into the program. In theory it should pause the program so I can break off the material. Then I will hit resume and it will run a finishing pass. Not sure if an M0 will work on the MR-1 or not.

Been absolutely great.

Now, I will blame a big part of my continued succession (with the STV) due to everything I learned with my Crossfire and Crossfire Pro.

Moving to the STV, my actual turn around from drawing to physical parts is even faster with how quick and efficient Optimum is.

Pair that with the fact that I force myself to walk away from the table while it’s cutting, knowing I won’t have any hiccups, is a huge relief as well.

I have to say though, there are plenty of things I like about Langmuir that would make me recommend them over something more…expensive. But after some experience, the STV is a great table offering stuff a novice wouldn’t really understand right away.

Even though the video is sped up a bit, the table does jog at 600ipm (with the ability to run/cut at 1,000ipm).

I especially love the parking feature, and use it every single cut.

what does that do?

The torch jogs up until it senses the proximity switch, then jogs over to your saved parking position.

Refer to the end of the video here (it’s in real-time).

In the controller software, there’s an Advanced tab and you go to Parking Presets.

You can enable or disable the option to park at the end of your programs; I leave mine enabled so it always parks.

You can save 10 different presets for parking, and just as easily override any one of them by simply jogging where you want your torch, and saving that position.

In this case, I jogged over to a spot above metal and saved it as my preset. After which I ran my program so after it finished cutting, it went to that spot to rest.

I really like the embossing detail your guys did. How did you achieve those

I really need to get on the ball and cut a dinosaur. Those things are freaking awesome. How well do they sell for you? Seems like they would be expensive materials wise. Lots of nesting.

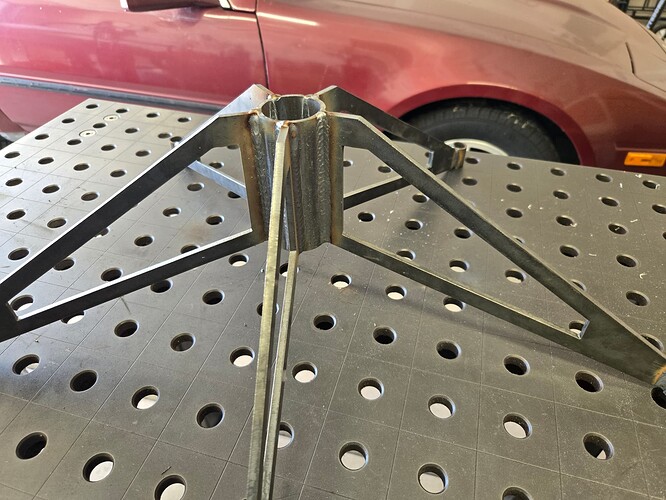

We dont sell the dyes at the moment. We make just for our needs at the moment. I think we’ve made some where around 10 different ones. Some have been one time use & some have been used on multiple other projects. They are typically made from 4 pieces of plate. The Circular one i posted is from 1/4 & 10ga material. The lincoln emblem was made from all 10ga material and has taken some abuse.