Well, the goodies have started to arrive! A whole bunch of endmills will be in next week …exciting times! ![]()

![]()

Wow a hole lot of toys---- tools. I don’t see center finders there.

I don’t see center finders there.

one proud Pappa there…the machine stork is on the way…

Top left is a Center finder, but I already have wigglers and a Laser center finder I use with the CNC Mini-Mill

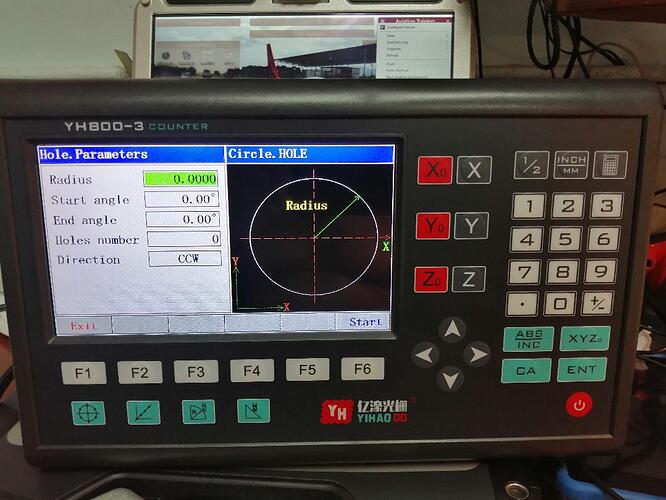

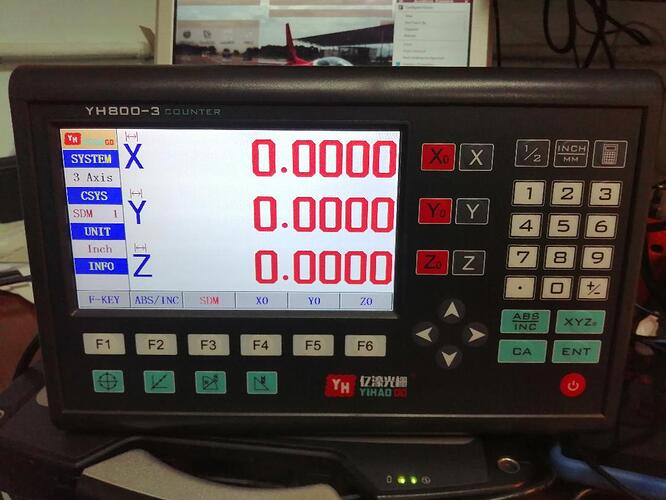

Configuration of the PM-935TS-3PH mill will be:

Hitachi WJ200-022SF VFD, PM 3-axis DRO, Align X-axis feed, Align Z-axis feed, 11-pc R8 Collet set, 52-pc Clamping set, 5" High Precision Vise, Keyless Drill Chuck, Leveling pads and Power Drawbar.

Completed two really nice work-lights today for the mill. Two cheap microphone booms and two Westinghouse 69032 LED downlighters. Each 12W, 6500K, they’re really bright and no shadows.

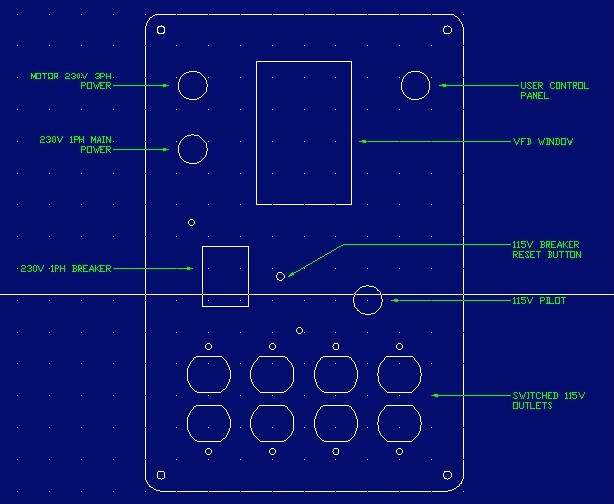

Also made the VFD mounts (CNC plasma cut). I’m mounting the VFD and all the relays, breakers etc inside the pedestial. There will be a removable lexan window for VFD front panel access.

Sorry about the messy workbench, too many things going on on it right now.

Cletus,

My wife calls my mill the milking machine. You’re off to a good start. That boring bar kit is real.nice.

The mill supplies and consumables will make the plasma table look inexpensive…

So, the plan is to replace the removable cover plate on either the backside or left-side of the pedestal with this custom plasma-cut power distribution panel (have to wait for the mill to actually arrive to size the cover plate properly).

All relays, contactors, VFD, 12VDC 2A power supply, etc will be housed inside the pedestal. The switched and fused (15A breaker) 115VAC outlets will supply the power feeds, illumination lamps, my powered Rotary Table, etc.

Got bored waiting for the table, so I through together a little press brake from some scrap I had laying around.

Nice! … Waiting for the new, expensive toys to arrive can be excruciating!

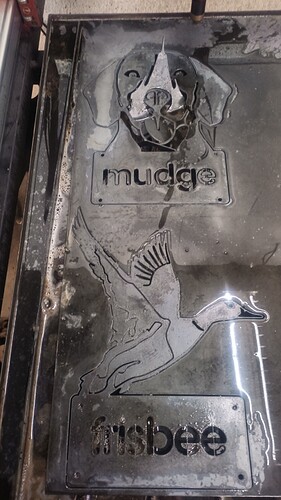

My brother was in town so I walked through the whole process with him. we designed up two signs for his kids stuffed toys not sure why but here is the results.

14ga mild steel running a hypertherm 85 with 45 amp shielded consumables at book settings.

Cad and cam was done in fusion 360.

These are about 11x16

Couple little fire pits…

Few other bits and pieces

Jump on my instagram if you guys want to see more

@murphs_metal_fabrication

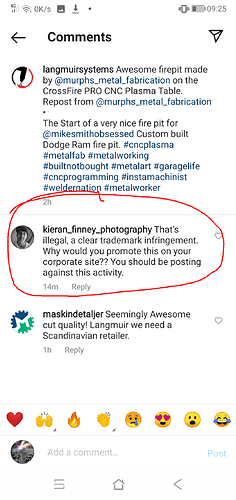

And like most boners this dude looks like a huge hypocrite.

Using automotive and beverage product placement in your photography.

What’s the difference really?

very interesting !

From my side of things, the fire pit its not a commercially available item and not sold for profit ! it is a birthday present for a close mate. The purpose of use regarding the logo and text is different from the registered trademarks purpose. From Langmuirs point of view I am not sure how it works !

Yes you are right tho !! Boner … you will find commercial photographers are all about ownership and copyright etc. I get it as I was a commercial photographer many years ago !

Coming from a business point of view, its not about the logo or the text. Its all about the cut quality and the precision of the Cross fire pro.

nice…even you balls look good…

My wife likes the way they look to.

Thought I’d try cutting some scrap 4x4 box tubing I had kicking around so I made this street number sign and tossed some solar mini lights in it. Real happy with how it turned out and now if someone asks if I can do something like this I can say “Why yes I can!” ![]()

Wall hanger.

Hung up in the gallery now.

Maybe somebody will like it and buy it.

I think that circle is 13 and 1/2 in

And here’s a small maquete of a larger stand we’re making for a large fossil.