I really like the bee sign

I tried one of these stands I posted earlier out of 10ga material.

I had to do some tweaking to the slots it wasn’t directly scalable.

Worked out ok.

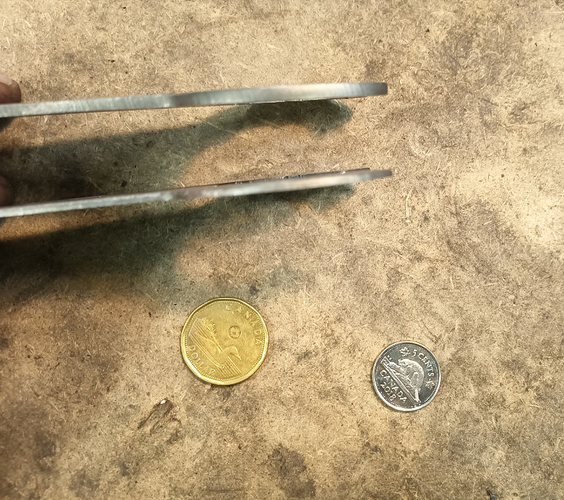

The real piece is going to be other quarter inch so I made a couple tests slot and tabs.

I ran these at 65 amps 90 inches per minute

The slot I did at 75 in per minute 65 amps

Happy enough with the results from the test to think about cutting the actual piece this Sunday out of 1/4

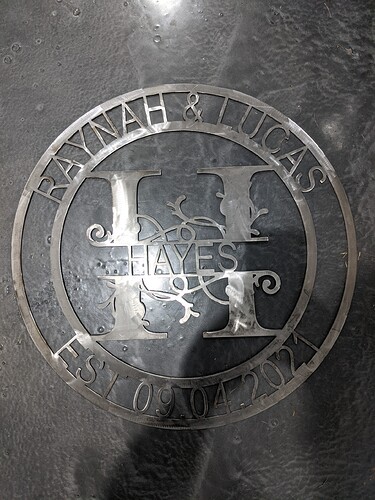

This is piece we made from my partners mom.

There is one for download on file share but for some reason it’s just a JPG.

I found a picture online and did a few changes to it, made it a double layered and this is how it turned out.

I love the look! Very nice piece. What is the finish on the foreground material?

Ferric nitrate water patina. warm to hot applied. then clear coat.

And the quarter inch ones are cut out ready for finish.

Pretty happy how it all turned out.

Hopefully you can get all the finishes done and have this piece delivered to the client for the coming weekend.

The bottom two pics are the quarter inch and the 8th inch version together

Hopefully, gone are the days for the notepad next to the mill with scribblings of dimensions. That said, I just built this and it will be mounted to my mill. My AutoCAD drawings (and I do draw everything) are all saved to my NAS system anyways, so I have full access from my Tablet ![]()

36" long cut into 14ga…raised letters on neck…

I placed the letters in place by “Crazy Glue” then flipped it over and TIG welded the letters in place

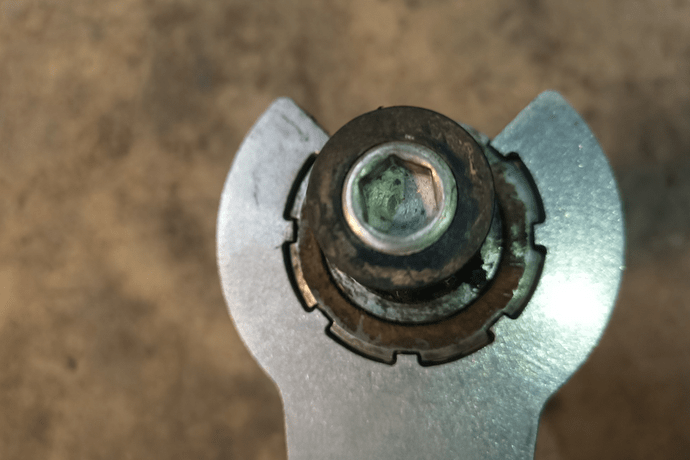

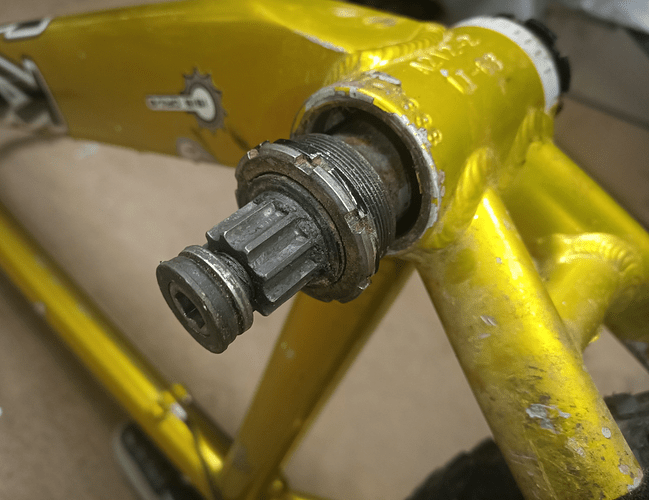

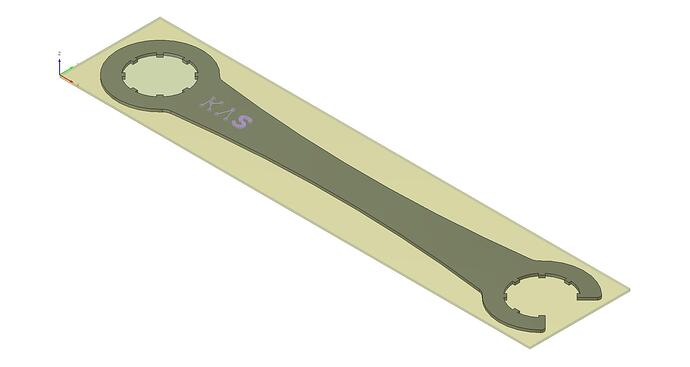

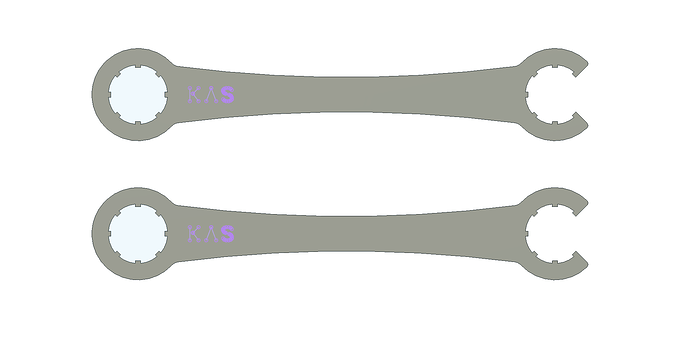

Made a couple mountain bike bottom bracket wrenches for a customer who couldn’t find one.

Took a few basic measurements with a caliper and then laid it out in fusion360 Cad and cam

One is made of 14 gauge and the other 10.

Both wrenches fit the spline straight off the table.

Very little dross at the high inches per minute

I dressed out both wrenches out a little.

Finished this fossil stand.

I think our client is going to take delivery Monday.

So the three different sizes of stands, the biggest is 1/4 the medium size is 10 gauge and the smallest is 14 gauge

Nice project, tig welds are perfect…

Not perfect for some reason there where a few spot that it didn’t cut all the way through. I think I need to fine tune the THC control.

What finish did you use on the fossil stands. It looks really nice!

Excellent work.

thanks…I appreciate that…

Don’t say that  his head is big enough

his head is big enough

But is is good work.

so, walk softly around madman? got it.

no…I do think he was talking about…ME!!!..

I prefer if you walk loudly so I know your coming