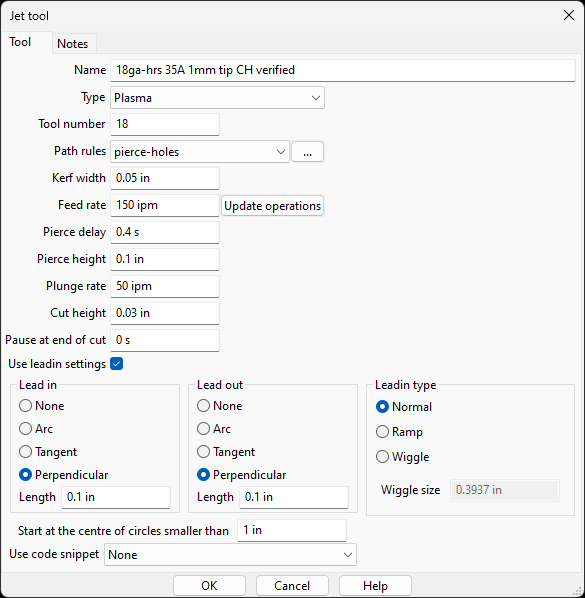

OK, trying Fusion CAM. Here are my sheetcam settings for 18ga steel. I spent several hours tweaking these for optimal cutting.

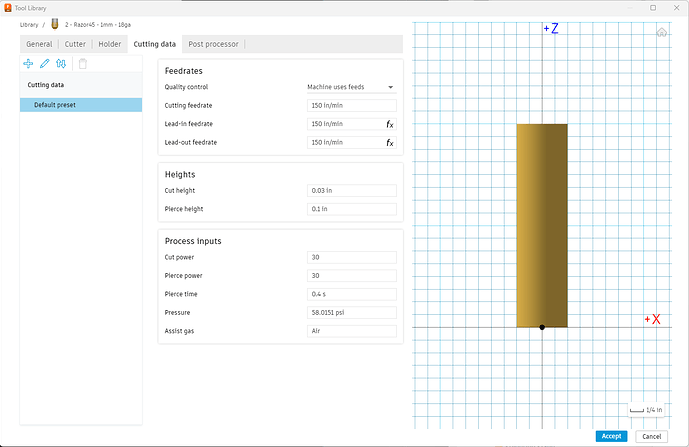

Set up a F360 plasma cutting tool

I don’t see a place to set plunge rate but I have feedrates, cut/pierce height and pierce time set.

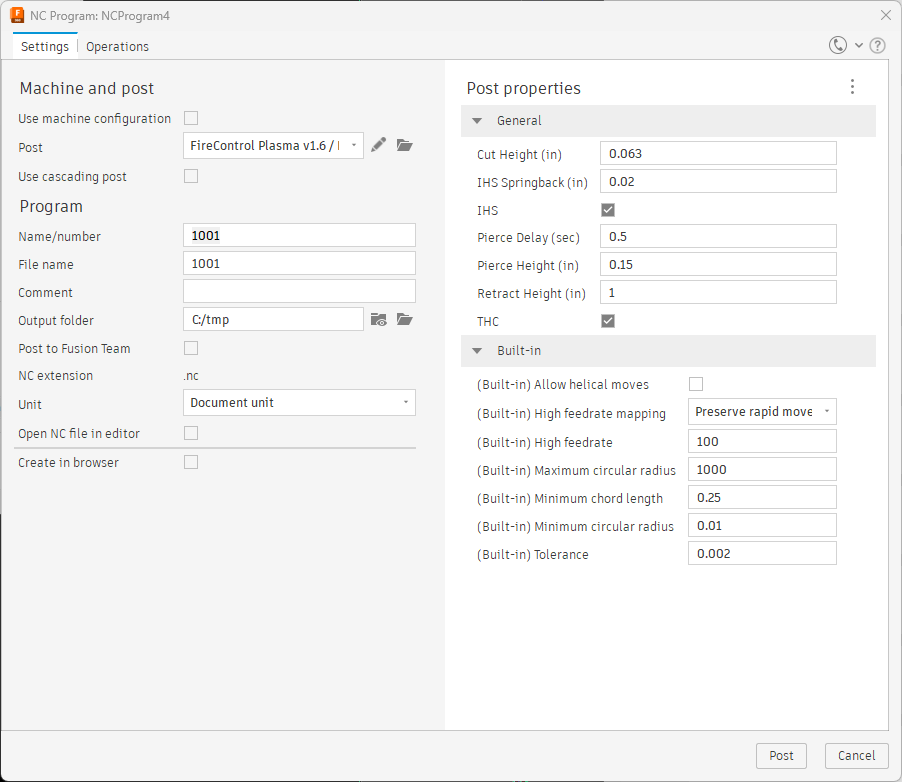

Here’s F360 post dialog

Cut height, pierce delay, pierce height are wrong. Do these not flow through from the tool settings?

from nc file

G0 X3.5166 Y4.1449

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.5

G0 Z0.063 (Cut Height)

H1

G1 X3.5536 Y3.9515 F150.

G3 X3.7236 Y4.4406 I0.085 J0.2446

G3 X3.5536 Y3.9515 I-0.085 J-0.2446

G1 X3.7025 Y4.0802

H0

M5

G0 Z1.

in the cps v1.6 file, I see the post properties are statically defined.

properties = {

ihsToggle: true,

thcToggle: true,

pierceDelay: 0.5, // specifies the delay to pierce in seconds

pierceHeight: 0.15, // specifies the pierce height

cutHeight: 0.063, // toggle between using G0 or G1 with a high Feedrate for rapid movements

retractHeight: 1, // the retract distance

ihsSpringback: 0.020,

};

I’ve spent hours tweaking my sheetcam tool settings to improve dimension accuracy, kerf, minimize dross and pierce hole size. I don’t see how using Fusion’s CAM/post gives me the tool flexibility of sheetcam. Especially when all the sheetcam values I tweaked are statically coded in the LS post cps file and have to be changed every job. If I’m missing something here, please let me know.