Good evening-

I just invested the $2500 to get the best machine I could buy.

I thought that getting this thing rolling would be a breeze but I was wrong.

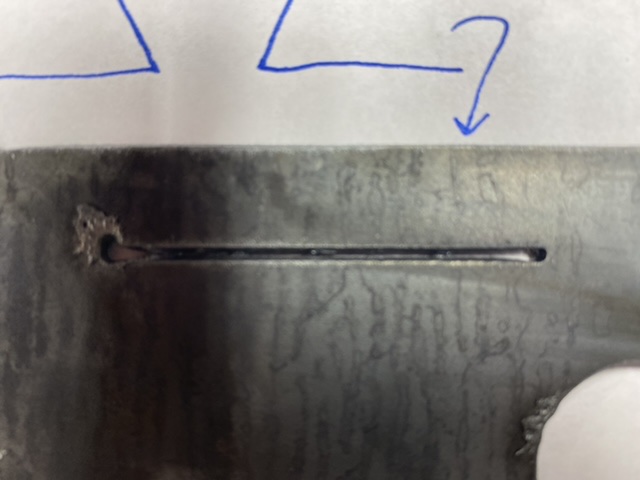

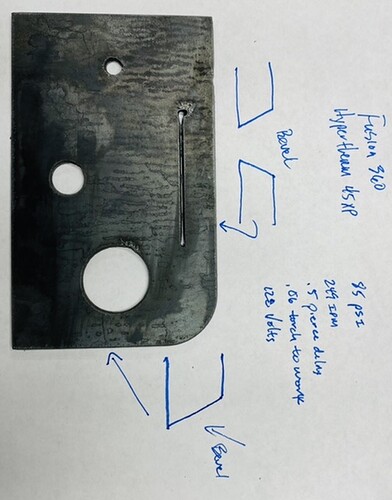

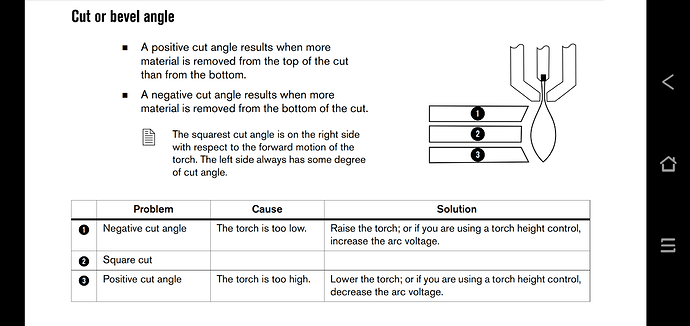

As you can see with the picture I am getting an excessive bevel and I cannot seem to tweak it away.

Also I am trying to cut straight lines but am also getting a nice divot on the initial pierce.

I have cut out so many of these things and no matter what I do I get the same bevel.

Any suggestions or a solution would be great. This thing has to be better than the $800 HF machine I had. Lol

Thanks.

What’s your metal thickness?

14 gauge?

You can dial your Pierce delay down in fire control. But set it to at least .5 in fusion first like you have

What kind of consumable pack are you using?

That I know it goes without saying but the ground is firmly clamped on the material?

1 Like

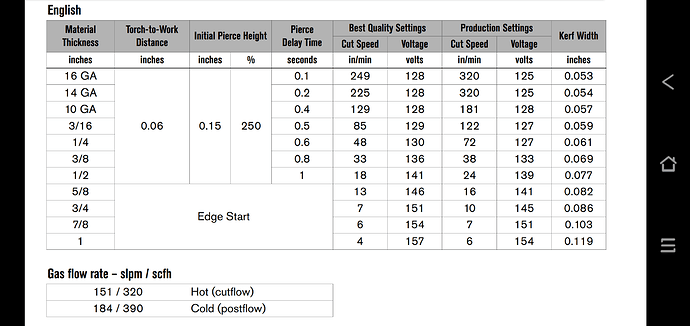

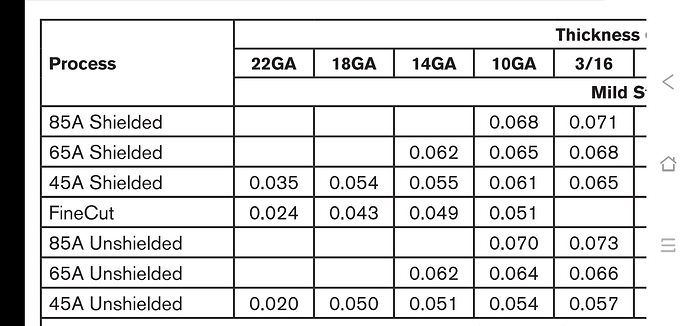

Looks like you may be running 16 gauge straight off the cut charts?

Running standard 45 amp consumables shielded?

And you’re running your machine at 45 amps?

Maybe verify that your torch to work distance is actually what you’re setting it for.

I usually run fine cuts at .075 I don’t know if this is right or wrong but I read it somewhere in a plasma spider post.

1 Like

Using 45amp shielded 16ga HR. At 35 amps.

Turn your machine up to 45 amps run those settings

Set your pierced delay down in fire control.

See how some of those adjustments treat you.

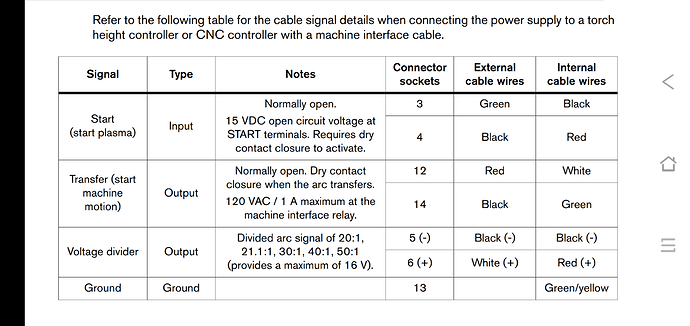

Thanks Tim whisperer! lots of good info there, can you put my mind at ease about wiring the 45xp? i’m about to setup all my electeonics on the pro and then finally the plasma.

I should have started here.

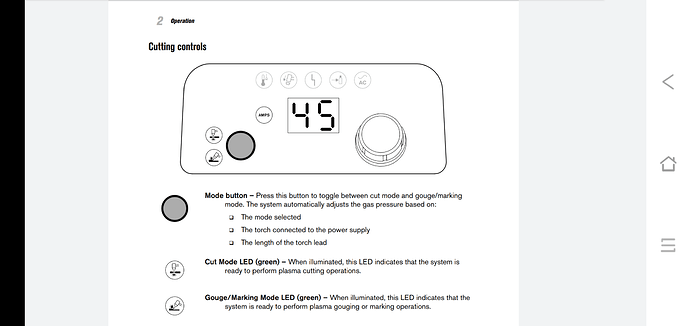

Check if your machine is set for cutting.

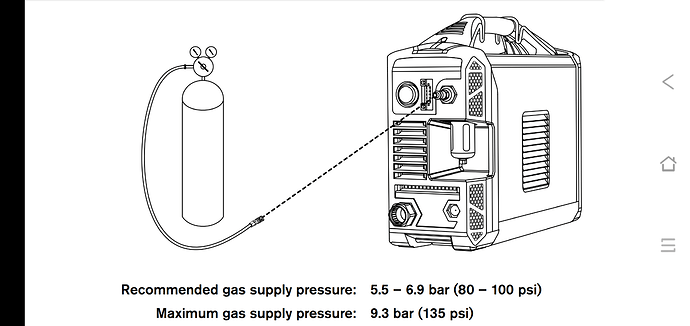

Also you can pump up your PSI a little bit so you’re not running right at the bare minimum

I know it shows the gas cylinder here picture but it’s just trying to depict any source of compressed gas.

1 Like

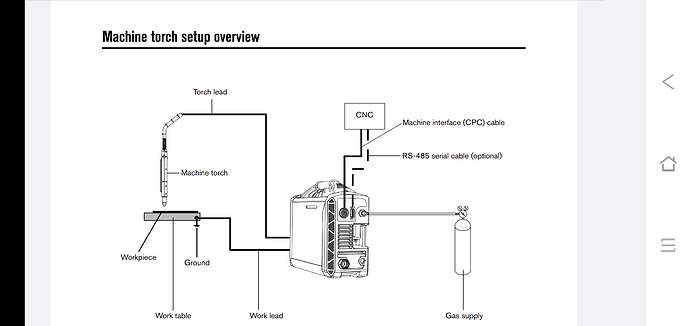

You have a very plug and play set up wiring wise with the 45xp.

Buy this cable from langmuir

45xp interconnect cable

Reference Materials

Full 45xp service manual

Langmuir THC support

Basic wiring overview from the manual

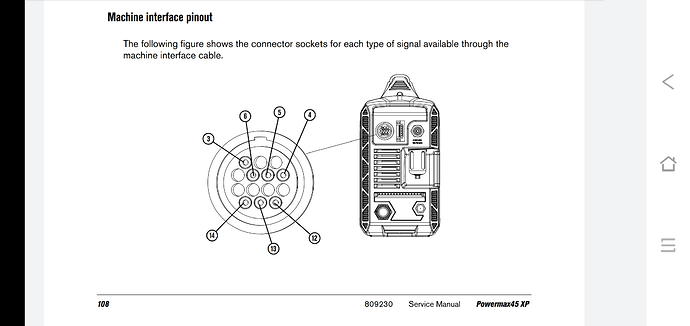

Here is the pin layout from the 45xp

Do you have a machine torch or hand torch?

1 Like

also for bevel…you show the hole at what looks like around 1/4"…hard to start cutting holes around that size and smaller perfect…keep that in mind.

1 Like

from my understanding that harness you can buy only works with a machine torch?

I got a handheld torch on the hypertherm 45xp

torch height control

crossfire pro

can’t wrap my head around the plasma part of the build. (sorry if i hijact this post)

Well not having machine torch is going to make it way less plug and Play.

You’ll have to search this forum there’s a few people that have modded their hand torch so that their CPC Port will function.

It’s specific to the 45XP hand torch. Zip tie the trigger and the #6 pin has to be removed from the connection assembly and inserted into the #8 port. This bypasses the trigger safety and lets the CNC port fire the torch.

To clarify a little, the Hyperthem knows whether a hand torch or machine torch is being used based on the position of that wire. Even with the trigger zip tied, a hand torch will not fire with a signal to the CNC. Moving that pin tells the HT a machine torch is being used and allows use of the CNC port.

Here’s one example.

2 Likes

Okay thanks mate, so the harness would be a waste i assume?

I’m gonna go wire all my electronics & then look into the plasma part. i’m feeling overwhelmed lol

Purchasing your 45xp with a machine torch would have made everything a lot simpler.

Is another link to the hand torch mod

You’re still going to need some kind of wiring between the langmuir electronics and your plasma machine.

Two wires for the fire torch contacts.

And two wires that measure the voltage that your torch height controller uses to make its decisions.

Northern-Boy:

i’m feeling overwhelmed

“There is only one way to eat an elephant: a bite at the time.”

2 Likes

So if i buy the machine torch and the harness it’ll just be plug-in and play?

Maybe i’ll look into the price of the machine torch. I wanted hypertherm to utilize their fine cut as i’ll be making signs & detailed art work.

Just the student loan only goes so far lol.

You won’t have to be doing any modding with the proper torch and wiring harness.

I find myself running standard 45 amp shielded consumables for signs and artwork a lot when I’m running 14 gauge.

What are you actually saving by going to finecuts on 14 gauge?

A tenth of a 16th kerf width?

Save your fine cuts for 16 gauge or less.

Maybe it’s worthwhile to put together a business proposal and get a business loan for your business?

2 Likes

machine torch and connect cable to cpc port from langmuir. functions on machine are accurate.

Turned up to 45 amps, run the same settings with fresh consumables.

If the cut is still unacceptable I would start looking at your power delivery to your plasma torch.

Are you running it on extension cord?

What kind of plug-in are you using?

What wire sizes feeds that plug in?

Is there line loss that is causing your machine not to be able to deliver the power?

That’s a very good point you bring up about how minimal the difference is.

Yes I will be securing a loan in the upcoming months, was hoping to run cash flow positive (not counting initial cash input) until I have proof of concept down.

Thanks for all the links regarding how to setup the hypertherm with what I have right now, I’ll make the decision today to either purchase a machine torch or mod what I have now.

1 Like