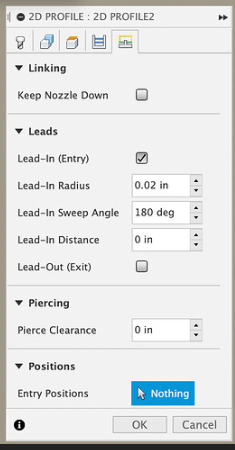

If you are using Fusion for CAM you might look at trying these settings:

.

.

I have been pretty successful with this method. Just keep changing your lead-in radius with a micro lead-in until it hits approximately the center. If Fusion hangs while doing it, change the sweep angle to 179 degrees. It seems to be a bit of a fluke with the difference between 180 and 179.

But, I think @brownfox idea is what you need to get to. This might help you do the 1/4" hole in the center, then clean the dross and run the tool path with a start in the center a second time with this type of configuration but going for your 3/4" hole size. Obviously, the pierce delay would need to be short during this second cutting action since there will not be material to cut during the pierce.