I took a somewhat different approach to building my mill, and I wanted to share the results. I will publish some deeper info into the casting process and final photos later on, but for now here are some build process photos. And in order to sprinkle a small amount of precision machine tool magic, I’ve given it an oversized name in german, Die Hochleistungs Werkbank.

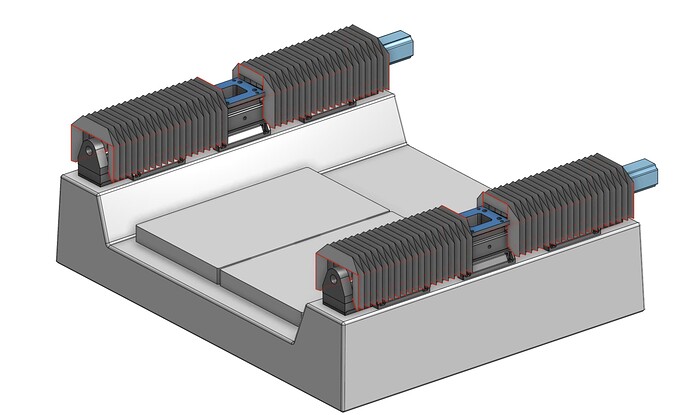

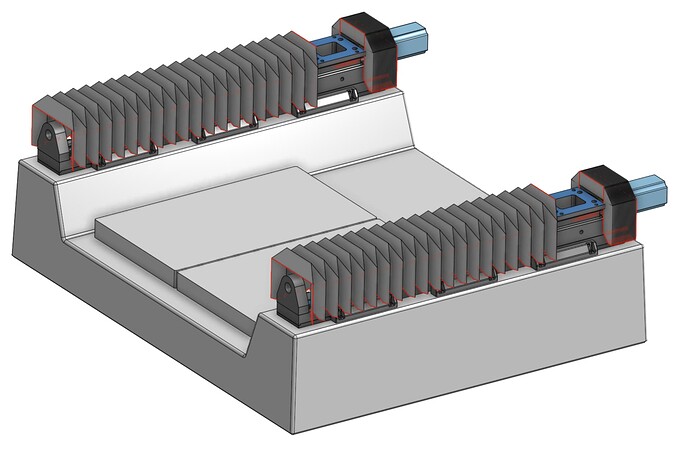

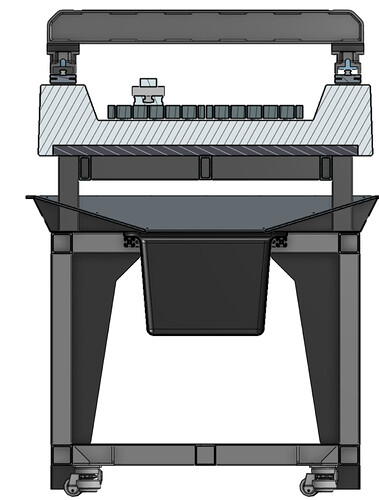

This machine has no drains- the whole table hovers above the chip bin like a Datron. I also built a new frame from welded 1/4 inch wall square tube. The fixture plates are 40mm thick, stress relieved cast iron, and are removable for fixturing directly to the machine bed if needed.

Just need to put on the enclosure and finish sealing up the flood coolant system. There will be a 5 gal sump below the chip bin and in-line filtration.

The mold with Bondo fillets, waxed and ready for fill. NOTE: if I did this again, I would use melamine board rather than MDF. Even with extensive waxing and a good amount of draft, it was a challenge to demold. The epoxy granite slurry is extremely abrasive, and easily wears through the wax barrier. This wouldn’t be a problem with melamine laminate board. The only reason I used MDF was because I already had it laying around.

A shot halfway through the epoxy granite pour. Extremely sticky stuff.

Here’s the casting inverted, before demolding and painting. The table + subframe weighs about 850 lbs.

The finished machine bed after demolding. Originally I was planning to leave it black, but ultimately I decided to give it a coat of Raptor epoxy primer (grey) and some 2k gloss topcoat - it’s easier to see dropped fasteners against a lighter grey.

Here’s the subframe and base frame stack up bolted together. The original sheet metal legs provide some extra stability, as well as some extra vibration support when the levelling feet are deployed, so that all the load isn’t on the levelling casters.

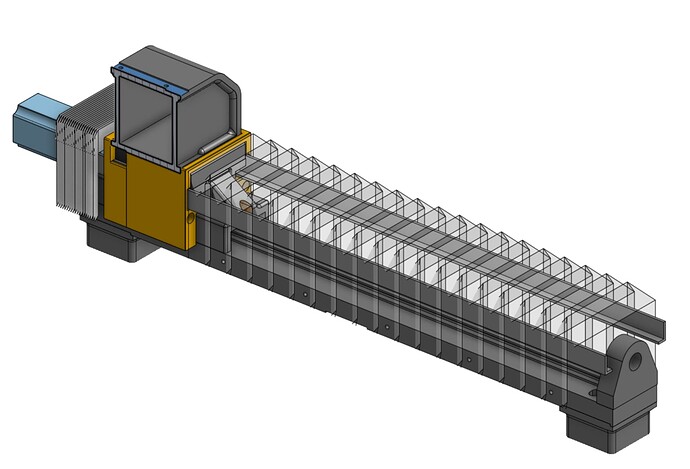

Y-axis risers made from 1 inch blachard ground 4140 stock, parkerized black to match the rest of the machine.