No mods to Z axis. On my other machine (still setting up, zero time right now) I built a taller water table. I run a 65amp and you can really see that flame push the water all over on this shallow table. So if you plan on cutting with more than 45 amp, Id suggest building a bigger table, but since you got an XR coming also you can run the larger amp on that and smaller on the PRO, thats what I plan on doing.

Very cool. That’s what I’m planning on doing with lri and xr… small part thin kerf and big part or thick stuff. How much height did you add on stantions?

I made two settings on my first set, 2 and 3". I left both machines 3" height. On this machine pictured with shallow water table I have alot of clearance. On the taller water table I added 1.5" or so, not as much clearance but plenty. Nice to just put a piece of 1/4 all the way through the machine.

I would love a copy of the stanchion file if your willing to share it!

Stanstion Plates.dxf (164.3 KB)

Thanks, those should work great!

That would be a great tool for pulling a dual engine car. Might come in handy for those guys that do those tractor pulls with multiple engines. They can pull there motors twice as fast in between rounds like a top fuel team. Lol.

I am so jealous

I feel ya I have a 400sqft warehouse with a small Enco gunsmithing lathe, a Enco mill, a Motocycle lift,big air compressor, a bench that has 5 Bullet reloading machines and a vise, and I got a once in a lifetime deal on a snap on tool box from my snap on dealer and when it showed up it was the biggest box I had ever saw. Plus a 24 gun safe and shelf to hold hundreds of thousands of Bullets and powder.

I have run out of room Quik. And I have my racebike in there and another bike I am restoring/resto-Modding. As crazy neat as I try to keep it is hard to work. My biggest problem is my trash can takes up to much space. Lol you cannot find a warehouse in my area right now and if you do the prices are to high for the size.

I am preparing to build my first shop on my property. But prices are high right now. But I guess all these are good problems to have.

Oh ya I forgot my new Langmuir Plasma Table. I just hope I can learn how to run it well. Let’s see more pictures of your shops so y’all can give us some ideas. Thanks

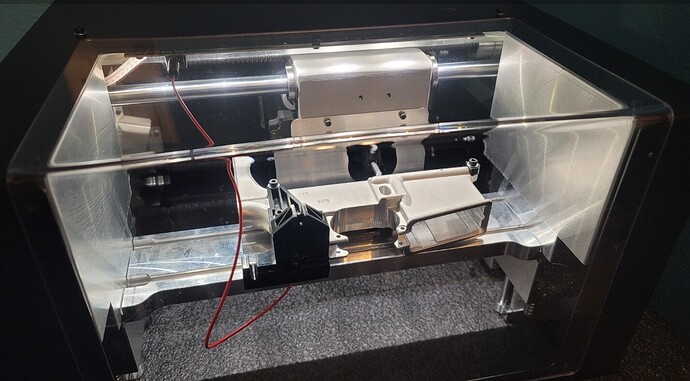

Well work has kept me away from getting some shop stuff done… but I found enough time to setup my little waterjet cutter and build my Crossfire PRO!

Just ran test cut a few minutes ago and all was perfect with THC and ITH. Only problem I ran into was a driver issue for the THC USB driver. But the windows 7 version of it on website for v2 units worked great.

I put the Razorweld cut 40 on mine and mine was one of the reversed torch on/off THC output swappers. Manual mentioned it and the card that came with the plasma cutter had their depiction correct, so went with that.

Only mod I’ve gotten to so far was tig welding the water bed halves together and welding on SS commercial food piping for the drain, and what will become the outside of the circulation system when I get to that. First time welding stainless, not the prettiest thing with gap filling the taper on the pan, but not a drop of water anywhere, so it’s a win.

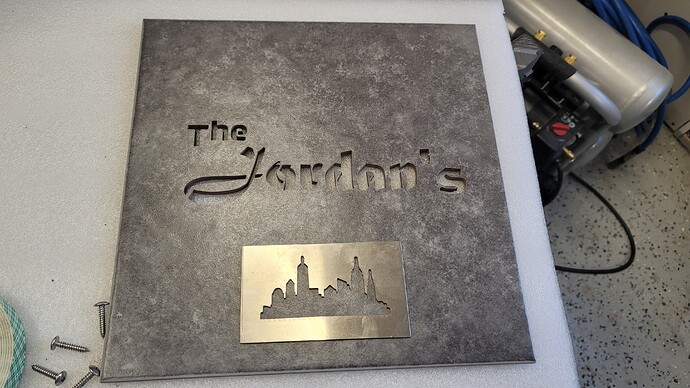

These are the first test cuts off the waterjet cutter from Wazer (not a typo).

3/8" Porcelain tile and 1/8" aluminum. A tip-up messed the “T” alignment. Super impressive manual, quality, and performance in a tiny package.

Kerf is 0.6mm, 80 grit garnet… aluminum cut 21 ipm. Porcelain 14 ipm. Fine cut settings left smooth vertical edges. Going to try some glass and then onto custom knife blades!

Underside of PRO with beginnings of circulation system. Put a glass sight tube in for flow check. Still have to 3D print my little waterwheel that drops in the glass tube.

Sump box & Pump will go after shutoff valve, then the filter cans, flow control, and back to table.

Sorry, trying to post pics but internet is so slow!

@eastcoastbullets … heres some more setup pics… Im knocking out one section at a time. This was the toughest with more electrical than anywhere else. Framing goes so fast, then all the details. Love the journey as much as the destination and all is good.

Pic is of the machine shop area. Tormach 1100MX cnc mill, 15L Slant pro cnc lathe, manual gun lathe, manual mill with DRO. Oil and chips OK here, wood dust not.

In the back area I’ve got the less messy cutters… Boss HP3655 150w laser with a rotary axis and O2 assist metal cutting… and the Wazer waterjet cutter. 18x12 beast slo-mo’s through literally anything. The back area is cleaner zone… no chips… mobile SS workbench toolboxes and System X wall organizer… still gotta plan that out and mount all the accessories. Sliding door gets big stuff and materials inside.

Here’s better shot of the back area. I have 3 zone mini Split AC / heat unit that keeps temp and humidity in comfy zone. Still some wiring to run for lights before I can finish up insulation and drywall…

Still so much to do… outside of that wonderful organized area (12x18 machine shop, 12x24 rear clean shop) is this disaster in progress. Plumbing my Quincy compressor into a full shop air system… hope nobody here is electrician! I’m waiting on the new 200 amp panel to get put on main service, so had to do some temp hookups to test toys…

At our first house I had everything in a 2 car garage…had a combo lathe/mill, cnc router and laser, plus my tools, painting, and workbenches all in same room. Always had sawdust coating metal stuff, oil into wood, and overspray worries.

So that’s why you see my 36x24 shop is divided up. The framing on left is beginning of woodshop area. My wood lathe and 36x24 cnc router are over there hiding. “T” shaped Wood working bench gets these beautiful babies built into it… 1945 Delta cast iron unisaw and same Era Dewalt radial arm saw… butter smooth old school power and quality.

The final area is above the woodshop. Same size as woodshop, it’s the clean, dust and oil free room where I’ll have my 1942 green design desk, assembly benches , and the painting booth / curing oven for my Cerakote setup. I have a vinyl cutter for cutting paint masks that’s gonna find a home up there. Lots of work up there. Gotta put in the booth air management system with the explosion proof vent fan for the vented walls of the booth. No more overspray zones!

The last frontier to tackle is the remaining shop floor… for now the PRO is by the welding cart next to the garage door… but when the XR shows up in October, they will both be on right side next to the plasma vent hood I’m working up in my head still…

Langmuir shipped out my 5 Arcflat welding benches this week, so I’m going to do some major organizing in this area to make room for them. Not totally sure how I’m going to set them up. Thinking U shape, but T or L might work good too. I have a huge 52" box brake and 50" stomp shear to wrangle into a convenient spot around it all.