That’s amazing ![]() . I only

. I only

I took time to draw out all the machine footprints over plans, definitely helped figuring electrical needs.

(upload://q70Z1tCYUxlqqQ8K2w5JnpRCi7x.jpeg)

holly lord f a duck!!!

I am so envious…

I am working out of 12 x 22 single car garage…which I hope to increase by 50%…unless the wife wants to park her car inside…then I am screwed…

@toolboy Man, you work what you got… I often feel a little bad for the neighbors in our first apartment 20 years ago. I made my first cnc router… 12x24, 30 Ipm rapid and a Drexel tool…lol… then a 4 axis foam cutters. All out of the 2nd bedroom.

But from there we shipped our little rc airplanes to 27 counties.

This was my thing https://youtu.be/E20Y3ShjcL0

Oh… and in 20 years, we’ve never parked a car inside lol

no way???

this was you???

I remember that thing…

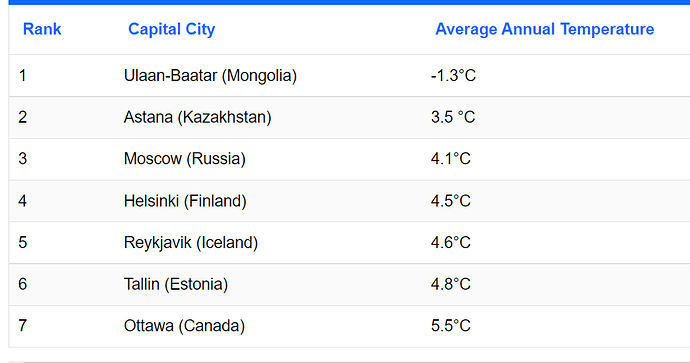

yes…but I live in Ottawa Canada…try telling your wife she does not get to get into a warm car…

Yup, that’s what staring out the window, drawing airplane pictures, and being called a problem child through school gets ya… Sold the business in 2005 to finish school.

Turned out OK I think…

@Dirty_Bill keep me posted on how that shop goes! Solid addition!

Holy crap! …That was you?? I too remember that thing. Someone brought one to the field, and we all wondered what the F? …hahahaha!

Lol, ya… I said the same thing when I saw one from some old 70s plans… I went looking for where to get one and thsre was nothing…

It was so fun… did tons of prototypes and airfoil tests until it was actually really easy and fun to fly. Definitely found a niche in a niche market… opened lots of doors.

From the cnc side of things, I needed a 4 axis cnc hotwire cutter… for cutting the wing cores and parts. that was one of my favorite machine design and builds ever. One block of foam cut from 3 sides in 4 operations… and it left all the parts done and a place for all the wood parts to slide in perfectly…I’ve got lots of love for precision and quality.

It warms my soul to share memories

Sweet. A man I can relate to.

I started woodworking out of a 10x28 minibarn at one house then a 12x20 at another. It was doable but it definitely teaches you to make the most efficient use of space. I have a 40x40 building now but I still keep everything in its place until I need it.

Let the fun level increase! Last box arrived yesterday. Also got the big compressor and my dryer setup…

Nice shop, I’ve got 2 900 sq ft. Garages. I’m getting mine the way I want it a little at a time.

You’ll love that dryer. I have the ADS20 and my Motorguard filter is always dry.

Oh wow! Really nice!

Great stuff. I agree with teaching kids some trades. Been on my heart for a while to have some shop classes (I build hotrods and parts). So to teach them basic tools and just get in their head a little bit that there is so much more to life than the phones, media and schools are offering.

One tip on the PRO. I made taller stanchion plates. Really helps with keeping rails away from the water and clearance is much better.

Got any pics of those taller plates setup?

Hmmm,Hmm, I like. Did z axis need mods?