I have been making signs for a few months today I ran into a new problem. When I try to generate a toolpath in F360 one loop (not small) does not create. Can someone look at it and let me know what I screwed up? Second since I am using F360 free how do I share the file?

You can post a DFX here.

Or you could zip and post your F3D file from fusion 360.

My guess right now is that it is a circular or Arc cut at an acute angle.

But let’s see some files or screenshots and go from there

Tim thanks for helping.

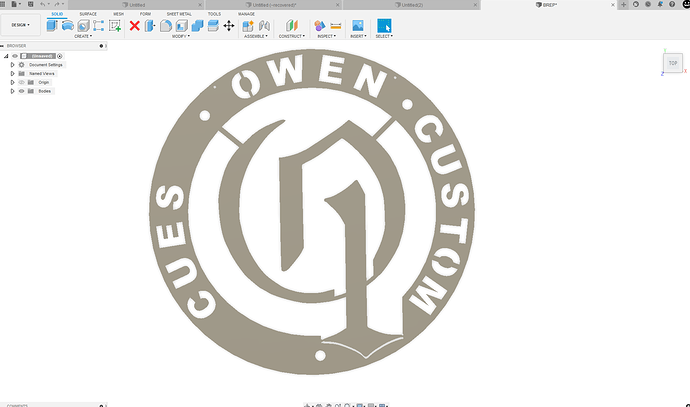

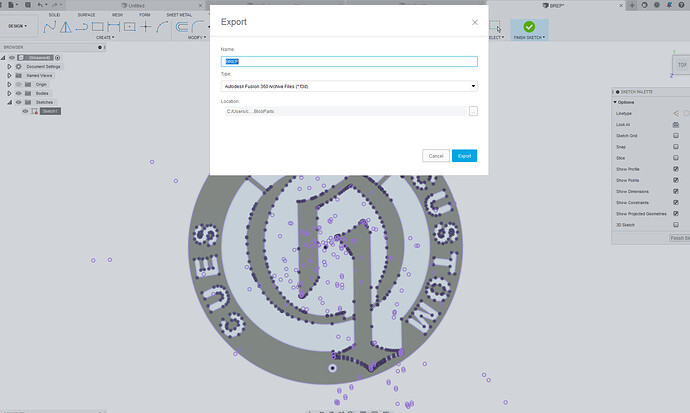

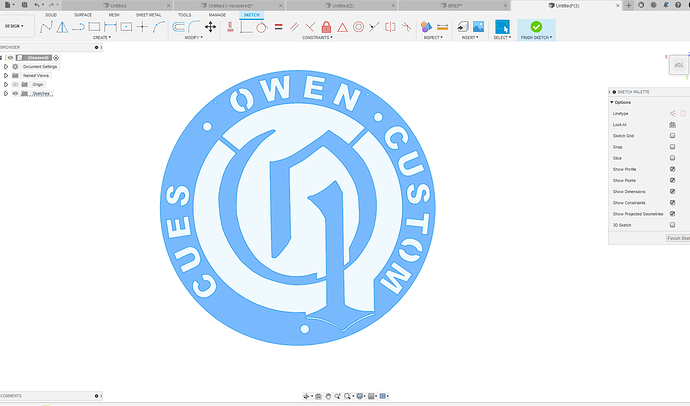

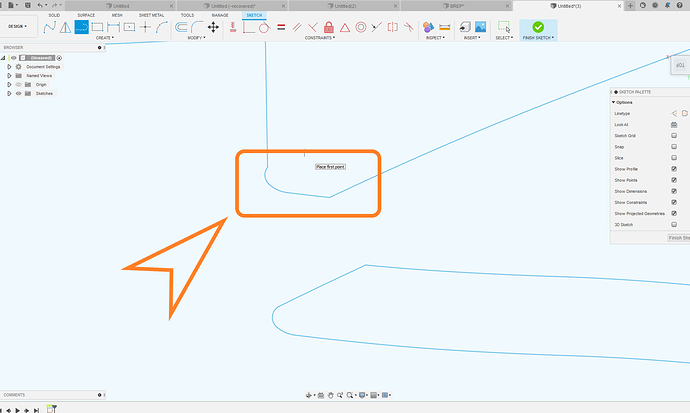

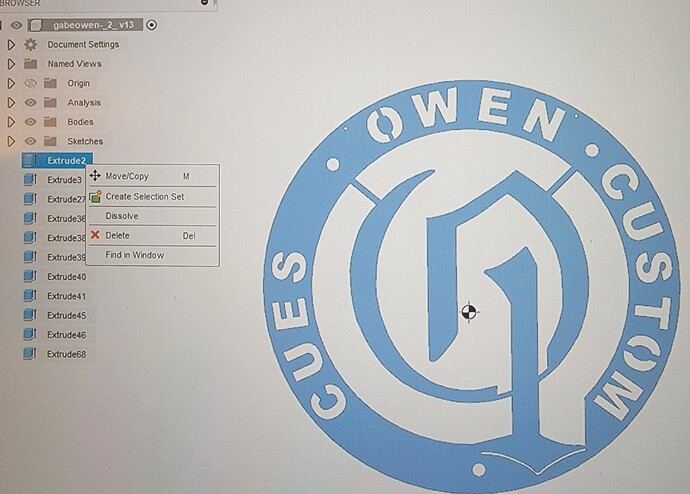

Maybe I am just inexperienced but Fusion(free) wont let me export a dxf. I have an f3d file The forrum wont allow me to upload a f3d. Here is an image. The left side drop next to custom will not generate

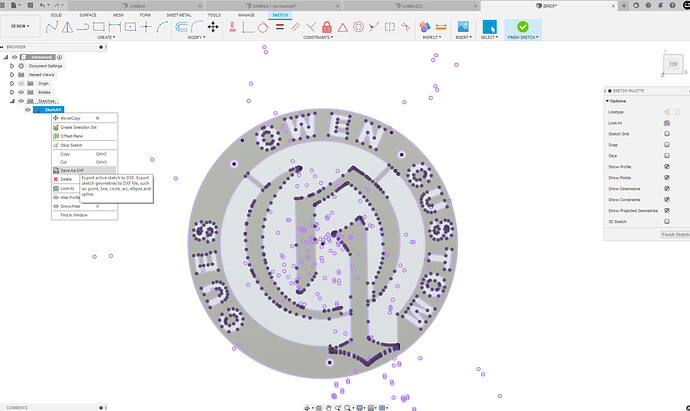

Here is a method to Export a DXF with a free version.

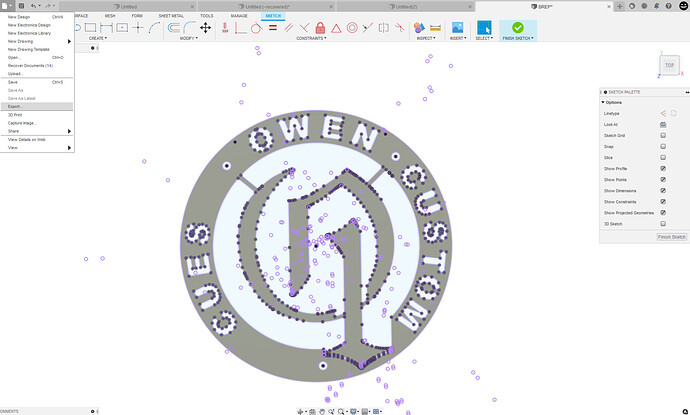

Here is where is export a f3d from fusion360 . not sure if this works in the free version.

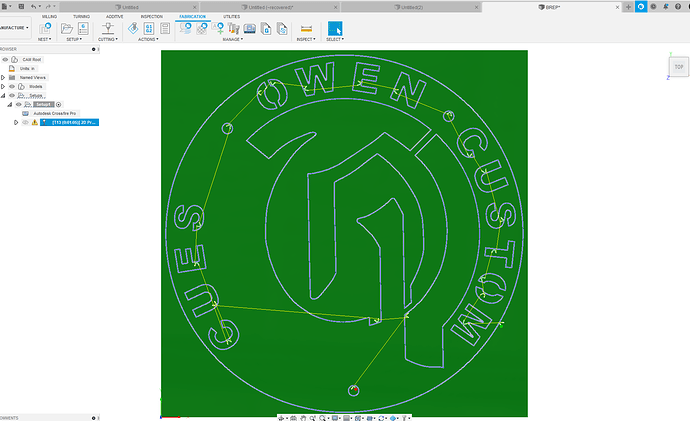

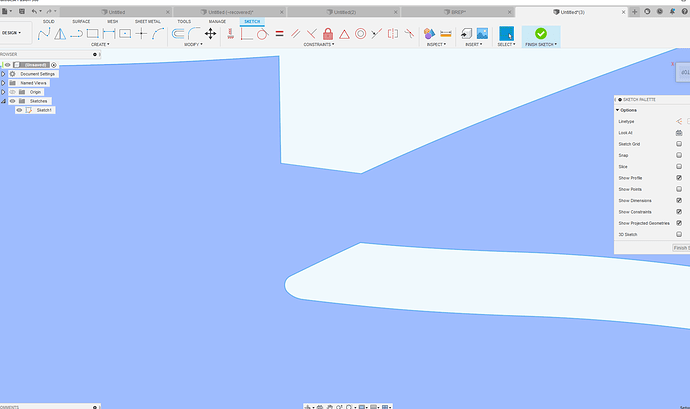

Here is the missing geometry

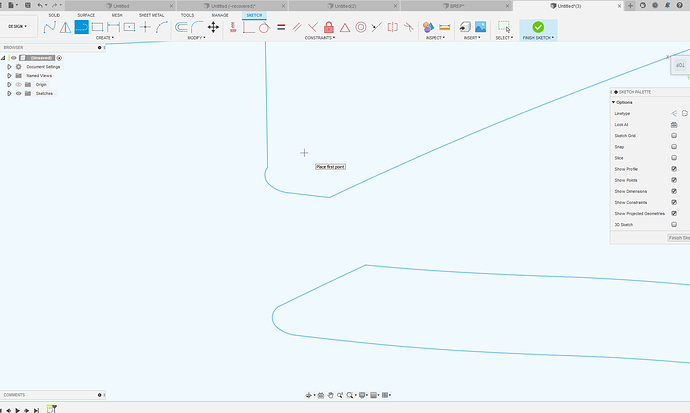

it is a circle to line intersection issue, here I go about repairing the issue.

Now fusion recognizes it and then includes it in the tool paths

Attached is a DXF with the fix.

Owens custom cues with fix.dxf (153.9 KB)

Hopefully this gets you cutting.

WOW I didnt expect so muI appreciate the explination as well as the fix. Thank you so much.

So I am still getting the same issue. I see that the toolpath created in yours, so that makes me think my F360 is different somehow. Maybe a parameter that I have different. Any ideas?

I don’t see what you see also on a right click.

I completely changed the shape of the area and it’s still not creating it. Grrrr

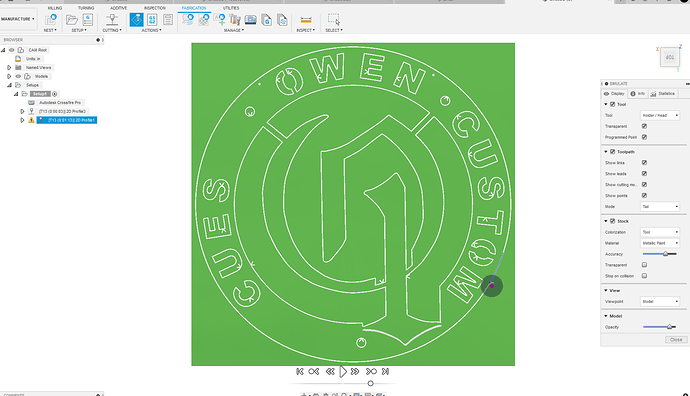

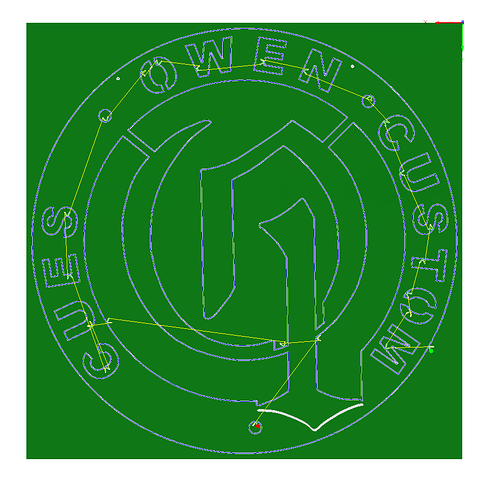

I finally got it. I had to change the design a bit. I created a bridge in the loop to narrow down the issue area. But to my surprise it created the toolpath. So I went with it and this is the result. Thanks again for all the help.

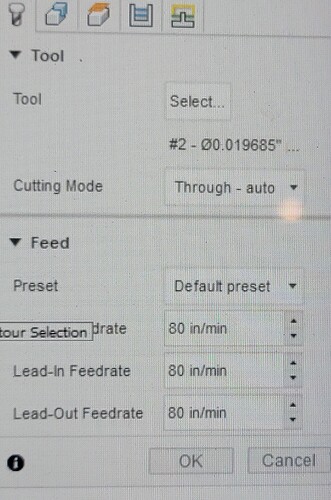

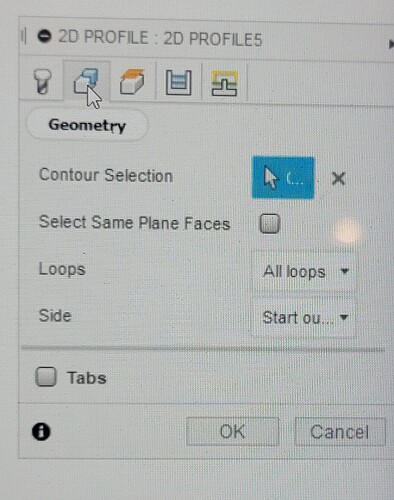

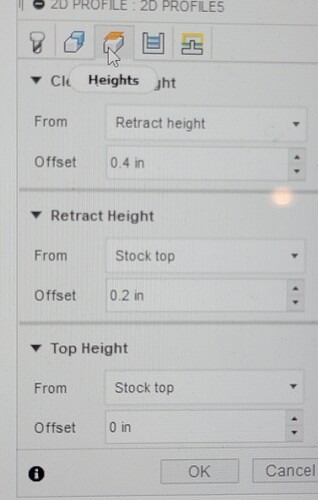

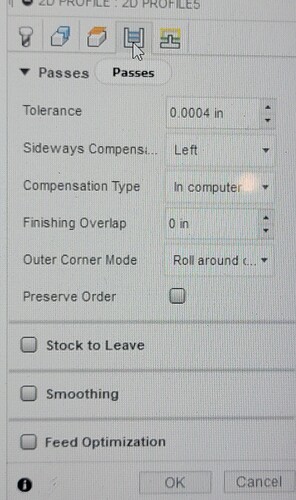

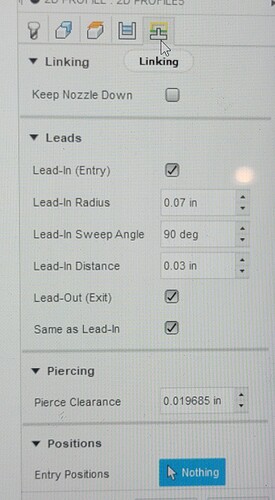

Post a few screenshots of your 2D profile menu that you’re using to generate the paths.

I’m wondering if you have your tolerance set slightly different than I do.

You can only export a sketch as a DXF.

select a sketch and right click.

The option " save as DXF " should be there.

You have a lot of extrudes on that drawing too and probably a lot of individual bodies making up that image and sometimes that itself can cause issues. You can go back into the original sketches and make changes and they’ll carry through all the steps you made.

That’s good you got it.

Well I certainly feel.like this better be a learning experience because I spent all day trying to get it to work when I could have started over. I decided I wanted to know what was going on so I could avoid this in the future.

I usually extrude my drawings I can’t say why other than it looks better to me and I have always done it that way…LOL

By the time I sent that I had tried lots of things, thinking it was a conflict and changing something small might get it. Turns out that did work.

I’m definitely running differently in lead in , out and Pierce clearances but that shouldn’t matter the real problem is fusion having an issue with circles intersecting lines.

I went back and played with it a little bit more and it would only repeat generating a tool path for that missing area about one time out of 10 with the fixed DXF.

So I looked at the sketch some more and on that missing area if you radius the top left inside corner where the arc and line meet it’ll generate a toolpath every time. A very small radius , micro.

This does come up in fusion360, it’s a known problem. I’ve seen it come up twice in these Busch signs before as well. I had a garden stake gnome and a cat that both did the same thing before. All case were a arc or a circle intersected with a line.

I have Found fusion360 to have a pretty hard learning curve too, can be overwhelming with all the options When does have glitches on top of that it can kills a guy’s confidence.

But I believe fusion is the way. ultimately you can design anything you want and when you get better at it you can go back and repair something and it changes everything ahead of that change to reflect it very convenient with complicated work.

Sign looks good nice to have a project done.

The guy sent me the logo and I obviously made the bridges to make a single piece. And had to make it a ring with the lettering. So I dropped the bottom of the “1” yeah thats a 1, through the ring to have some symmetry. That’s the decision that took 7 hrs of my life I can’t get back. Lol . Hopefully I can learn from this. Thanks again.