After “fighting” Fusion 360 for over 9 month, I decided to give Sheetcam a try. I wish I had done it a lot sooner. Fusion 360 capabilities are awesome for those who design complex parts. But I’m sure that over 95% of the people using the Crossfire do not need those capabilities. If you are having 100% success with Fusion 360, continue to use it, but if you are having issues, do yourself a favor, spend another $150 and buy Sheetcam. It is a lot simpler and the results are great. again, I wish I had done it before. Watch the training videos in YouTube. Enjoy!

I am not a big fan of Fusion 360. Were there any barriers to using Sheetcam for you. Do you have any sort of simple guide to setup for it? Can we use that LS post file the same we do for fusion to post with?

Hey Langmuir why don’t you make a Deal with Sheetcam?

I watched the training videos before I made the purchase. I found it to be a lot simpler than Fusion 360. Since I only cut 16 sheetmetal, I only had to make one tool setup. Download a free (limited) trial copy and give it a shot. You can always go back to the training videos if you have any questions. Let me know how it goes for you.

Im cutting much larger metal and many different sizes and lots of different hole and pin sizes. However each piece is not complex maybe 50 to 100 lines of code max. I will do that.

Hmmmm, good post OP, thanks, got me thinking.

SheetCam also has a good user forum where most questions will get answered by the developer. But watch the videos put out by ArcLight Dynamics on youtube to get started.

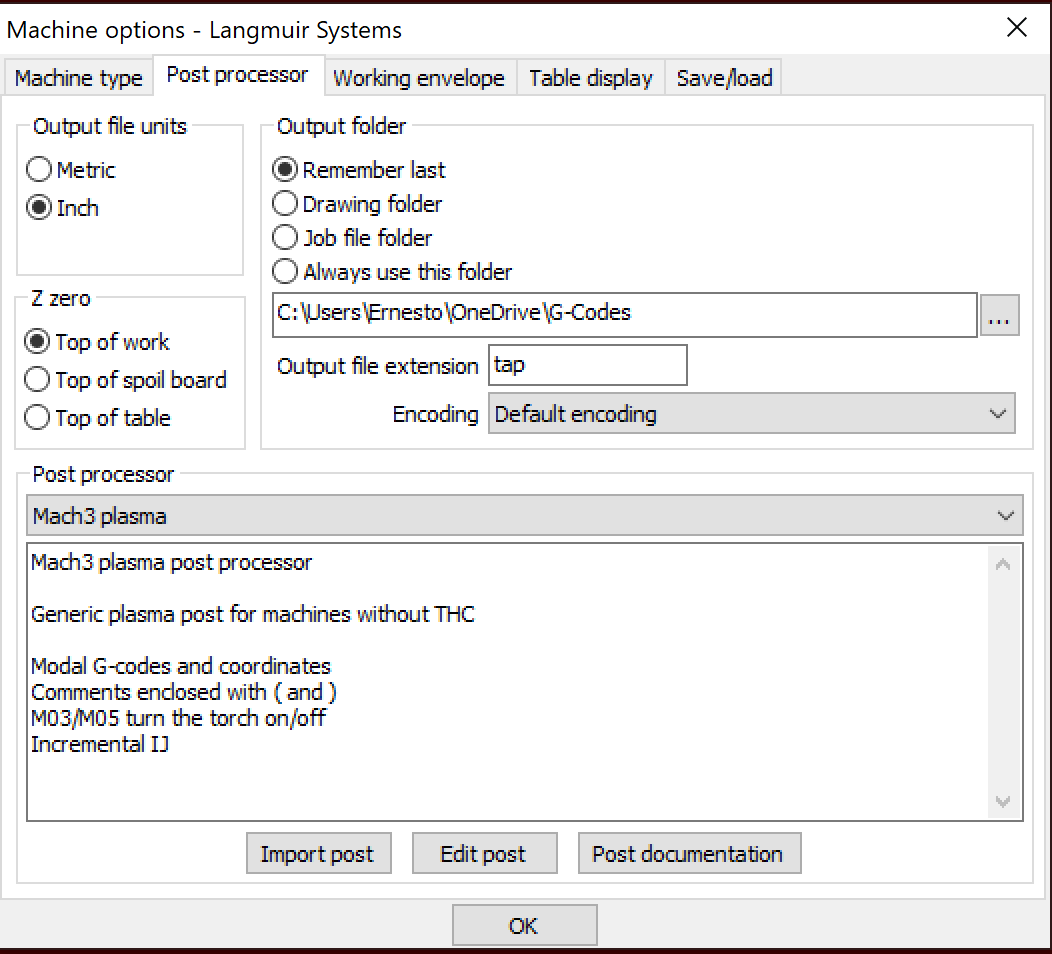

You wont be able to use the same Post from Fusion360 as a post is ‘married’ to the software that consumes it. Perhaps @aycompay can tell you which one he uses. There is a "Mach 3 no Z " in the list of preconfigured posts.

It’s pretty versatile, I haven’t used it for plasma cutting yet, but after watching some videos found it easy to use for my existing CNC machine.

I uploaded a modified Sheetcam post processor for Mach3 that outputs correct millisecond based tap files so it will work for sub-second delays despite the Mach3 bug.

A couple of forum members have tried it but I’m waiting to see if anything wonky happens with the files before adding a new thread with it attached. If you want to try it, just search for Sheetcam post processor.

I’m going to do a live trial tomorrow with it.

I like sheetcam alot better. Fusion was ok until updates came and then I couldn’t even get it to work. The only thing I don’t like on sheetcam which you can prolly change just not in a grove to experiment…is it cuts all the inside cuts first, then outside. So what has happens to me every once in a while is, I get a tip up or something and ruins a sheet. At least with fusion I was able to save some of my sheets cause it didn’t cut inside cuts on the whole sheet. It does inside/outside per part. Fusion has alot more Gcode than sheetcam, easier to navigate back with sheetcam to reset a program if need. Def just try sheetcam you won’t go back.

Do you know you can pick and choose the curves you want to cut out first and profile them and them choose the other ones and do another profile? I’m having issues with my computer right now but I’ll send you a quick video on how to do that. Give me a couple of days

I figured you could, just honestly havent’ taken the time to look into it. I have a ton of files most all are sheetcam, very few I use from fusion still. I have some programmed for when I was using the xp30 and now I have all new files I use for the xp45. Would like to see the video. would be nice to cut all inside stuff then outside on half my sheet then do that on the remaining sheet, be worth a shot to see how it goes. One other thing I’d like to do is study the path the machine makes after a cut, Iv noticed it on fusion and sheetcam, it will travel right through a part the was just cut and if that part didn’t drop all the way it collides with the torch. Not often does it happen but the extra control in programming would be worth the time esp if I’m using these files every week.

Use the Contour tool in Sheetcam (the C in the icon bar on the right). Send the curves/lines you want grouped together in a cutting operation to a new layer (hover over the line and right click). Then click the torch tool in the lower left to define a new cutting operation and set it to tool, layer, direction, etc.

You can drag the different operations up & down in that stack so you can make them execute in any order you want.

valuable information - I guess it would help if I read the manual on sheetcam. better yet, it would be better if I had 15 more hours in the day.

the other day I cut out some pumpkins for the wife and one of the cut pieces tipped up. I was able to grab it with a magnet, but if this were a production run of many pieces, I wouldn’t have been watching it at all.

That is basically what I do just only two layers. I select all insides, then all outsides. I set parameters to each layer. Ex. inside cuts get “inside cut” I attach a path rule to them and cut in CC motion. Outside I program differently. So basically I could do this operation as many times as I want? I’ll check it out and start playing with it. Maybe make 4 layers and try that first. Thanks for the feedback.

Yes. Typically I’ll have 4 or 5 cut paths/operations defined.

. Lines to cut that don’t make up an enclosed shape so there’s no offset or lead-in/lead-out

. Small holes where I can’t fit a lead-in

. Medium holes where I have to adjust the type or length of a lead-in

. Large holes with my normal lead-in value (twice my kerf setting)

. Outside cut

If I have something with a lot of close cuts I may break that area into a couple of new layers and cut the pieces in different groups so I can minimize warping or give me time to grab a tip up.

Also I’ll use the Start (S icon) adjusting function to manually change the starting point of different cuts or order so I can minimize warping/tip-ups as well.

Lots of options with Sheetcam.

So I gotta ask James… do you prefer sheetcam? I am really having a tough time in 360. It’s simply not intuitive. Sketchup is so much more user friendly.

If I’m not doing the design in Fusion I use Sheetcam.

But it’s $150 I think so one more expense that some folks won’t want to spend.

The post processor I posted up here (my mod that takes care of the seconds/milliseconds issue for Mach3) creates nice tight code too.

I have been using sheetcam from day one. One look at 360 and I said no. Reading all the frustration here on using 360…that costs more then $150.

I don’t really care for frustration…i like easy.

Sheetcam=easy