Before you pour. Redesign the drains. They will drive you nuts. If I could do it over that would be my only upgrade. No less than 3/4" if I could.

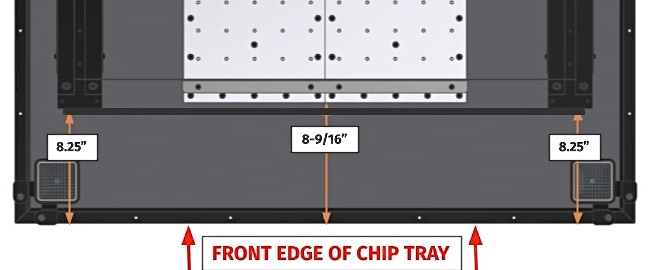

If you leave the front edge of the plate in the original location that means the larger plate will extend rearward by an extra 4” correct?. So if you are planning to surface the plate using a fly cutter, say 2-1/2” diameter, it won’t reach far enough back to finish the plate. You’ll have to flip the gantry 180 degrees and tram the whole thing in again to reach the last couple inches.

If the Y travel is 21.8” and assuming the original plate location were perfectly centered you have 10.9” travel for 10” of plate…no problem. But if you’re out 14” you’ll need a 6.25” diameter fly cutter minimum and it wouldn’t reach the far outside corners due to the cutter’s radius.

Check with Fieroguru, he’s at the fly cutting stage of an oversized plate as we speak.

I have a 24 x 30 plate using the two Langmuir plates with a 4" spacer in the center and a 10" plate across the rear and I kept it centered between the Y-rails. I used the stock front of pan to baseplate dimension and with the 2" flycutter was able to surface about 1 1/4" of the rear plate.

What I noticed while flycutting was that using the stock front dimension for the baseplate left quite a bit of unused travel on the Y-axis. My plate could have been 2" inches further forward and I would have been able to surface it. When I flip my X-axis back around, I can take a picture of this available room at the front.

Why 3/4"? It’s just fluid isn’t it? Although the screens don’t have much to grab hold of and I’m sure some chips get in. There is a lot of drain discussion for sure. I was able to get a good bite on the drain nipple by scuffing it with 80grit in the circumference direction. Boy, that is a bad design.

Do they not not drain well in real life? Water seems to go through the existing system when I just pour it in the drain.

Thanks,

Sbdon

How is the cut coverage in the X direction?

If the baseplate is moved 2" fwd could you surface 24" with a 2 1/2" flycutter?

Sbdon

They are terrible. The screens don’t fit well and clog up several times times a week.

It’s to late for me to fix it. But you can address this issue before you pour.

Get some bronze or pvc bulkheads and re- plumb it. 3/4 would be my choice. The splitters and the chips get stuck in the 1/4 bulkheads. Don’t get me wrong I just love this mill.

Print these from TPU (thanks to MrmachineTX) they will change your life!

That says a lot. Thanks Bigdaddy2166.

Sbdon

I also found that the baseplate could be a lot farther forward (or longer). I can’t really use the forward couple of inches of travel. I’m probably going to make a tool setter post that lives up there so that I’m losing functional workspace to the tool setter.

The large SMW plates are interesting and I’d probably have considered them if starting from scratch. A big continuous grid would be really nice for setup and having stops in the table. It’s a little too expensive to switch to since I already have a SMW Langmuir pallet vise.

On coolant — I’m surprised that more people aren’t using MQL. It’s so much cleaner and easier than dealing with flood. This is my first time really using it and I love it so far. I’ve used flood coolant on my other machines, but found that it’s not well suited to home machines that can lie idle for long periods of time.

Can you elaborate a bit. Are you only talking about the drains themselves? Is it a redesign with a larger drain?

Sbdon

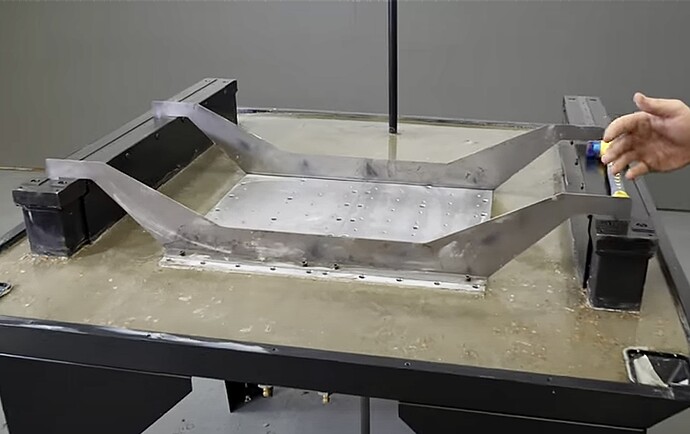

Here is my finished 24x30 baseplate. The 2.5" 4 insert flycutter hangs over the edge of the plate about 3/4" or so.

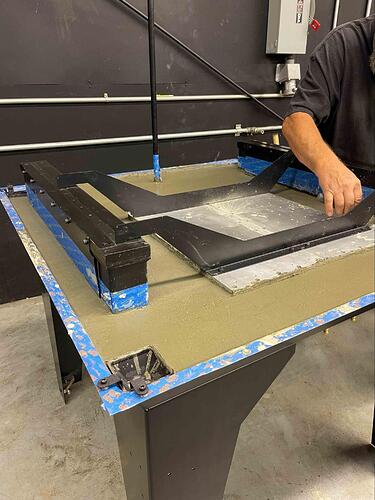

Here is a picture of the wasted space up front with a 2.5" facing tool for reference. The plate could have easily been 2" further forward. It would be a great spot for a cool changer base, but would require drilling the epoxy and concrete for more anchors.

It’s basically a gasket that fits around the stock drain screens. They fit nice and tight and don’t lift out easily even when you blast them with air. But have a tab to pull them out easily when needed.

This is why I said “assuming”.

Last year I pointed out that the plates were set further back in the video tutorial than they were in the prototype photos.

We were told this change was necessary to center the plate better but I always planned to verify JIC. Maybe it should have moved back somewhat but from what people are saying, not 2+”.

Since the Y travel is shorter it sounds like there will only be 0.130” of overlap with a 2.5” fly cutter. So the plate position has to be almost perfect or you’ll be hand filing some edges. But that shouldn’t be a big deal…I think the plates look better with a slight beveled edge anyway.

Don’t have a 3 printer. I need one!! I have tried scotchbrite pads, weighted down the screens. Just to much stuff gets by the screen through the sides.

I am contemplating coring through and out the bottom.

I saw this post while working with my machine, so I measured my offsets. When Y is jogged all the way forward the spindle comes out 1-3/8" past the front of the bed. When Y is jogged all the way back my spindle is right on the tail end of the bed.

If I had shifted it about 5/8" forward of their instructions I would have had the bed roughly centered.

On the other hand, of all of my possible complaints about this machine this is near the bottom of the list. It’s overall a good machine and it has a huge X/Y size for it’s capabilities.

Gotta love these forums. Super helpful. Thanks to all.

Sbdon

Heads up that the baseplate is purposefully not centered. It has to do with where the baseplate anchors are in relation to the front tie plate that’s embedded in the concrete. Centering the baseplate could compromise the strength of the concrete around the anchors.

Like what Daniel is saying. Moving only 5/8” forward, the anchor bolts will likely touch or push against the tie bar I’ve drawn in place.

But based on Fieroguru’s pic it could move 1-1/4” forward with the spindle center reaching the edge of the plate.

The description on the smw website says there are 1/4" holes for the tool setter but I can’t figure out where they are. Do they exist and if so, where are they?