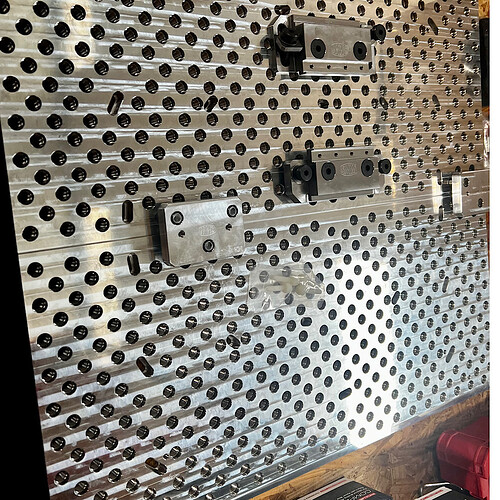

Had the first full size plate designed & built for the mr1. She’s a beauty. Need to get building my machine. They are available now on SMW site.

Very Nice. 2 Pieces Right? I had thought about this.

Yes 2 piece. , they talked me into it for shipping and faster production over the one piece. The alignment jigs are sitting on there.

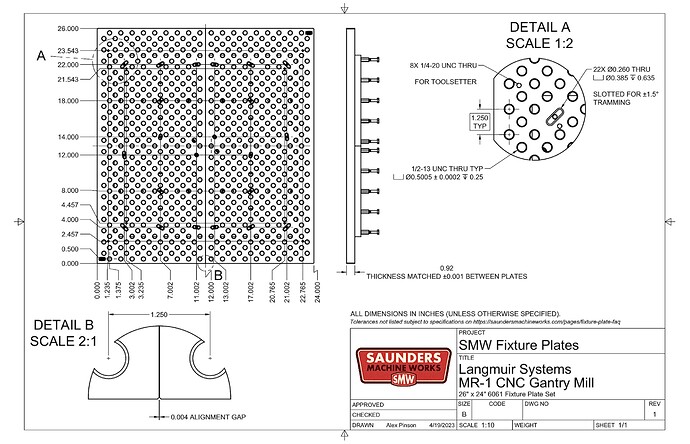

whats the dimensions?

Let’s get that thing built so we can see what it looks like installed.

$ 1200 dollars. That’s almost a 1/4 of the price of the machine. I realize that they are pretty. You still have to surface it after you install it. There goes the nice SMW logo. Just my two cents…

It looks to me like this is installed over the original fixture plate. Presumably (hopefully) there is decent parallelism on the Saunders plate.

I don’t hate this, but it does seem like overkill. Then again my build has also blown past all reasonable budget sensibility as well…

I looked at it as increased work holding. I like the mod vise setup , and these plates don’t reed to be surfaced. But if they do I’m not really worried about a logo , and their is zero sensibility on what I spend money on. Lol. Like zero.

So, you don’t have to surface it in parallel with the splndle? You are setting it in the concrete correct? Or are you anchoring it down to the original plate? The drawing shows the anchors in the bottom.

If you are anchoring it in the concrete than that logo will be gone. Because you will have to surface it. I do like the increased size. I’m also glad that the price is no object. It will be awesome addition.

I do have a entire SMW pallet and set of extra vises with extra steel jaws. I also have soft jaws for them if your interested.

They are the 1/2" style. I will make someone a good deal… (Sold)

The drawing is of the original plate that they have attached. Then the other is a the build sheet on the fixture plate. This bolts and trams in on top of the embedded baseplate over hangs a few inches. Which you can add more support if needed during your pour.

I may be interested shoot me a pm with price

Man I need one.

Shoot, I just noticed for $1200 you’re getting an aluminum plate, not his steel plates. makes it a bit less worth the price. will have to think on this.

SMW makes fixture plates out of 6061, 7075 aluminum, and 4140 steel. If you wanted 4140 steel in a 24” x 26” finished plate I think it would cost more than the whole mill. Am I wrong?

A little off topic but certainly connected. I went a slightly different route. I F360’d a 24in x 24in base plate and sent it off to Xometry. Doing it in MIC-6 Al. The question is should all oversize plates be centered between the Y rails with the standard front edge dimension from the front of the MR-1 tray. Might be the only way to do it but don’t want to do the pour and find out I should have done it differently. That would be bad.

Thanks,

Sbdon

@ Bigdaddy2166,

You sold your SMW vices, etc. I think you really like the Langmuir vices - correct?

Thanks,

Sbdon

Have not lost a part out of the langmuir vises since. I’m sure SMW vises have there place but, not for what I’m making. Not to mention that the langmuir vise is only marginally taller. The only downfall is the fact that the rear jaw does not move.