This is a cool project. I’m wondering if something like this Bear Crawl Heavy-Duty Mobile Base at Grizzly.com would be better for most people.

welcome to the forum…

problem with your option is that the MR1 has a base of 48" x 48"

the rolling base you suggested only goes 29" x 29"

not to mention although it allows up to 1200 lbs…the MR1 needs a very solid reduced vibration base…this would tend to wobble…

Yes, the Bear Crawl is not nearly stable enough to put the MR1 on. Those bases are great and an awesome buy I have a couple.

My MR-1 is on the way! I’m building a skid similar to this. I was wondering if I could get the measurements of the base from the centers of the leveling feet @Bigdaddy2166 (or anybody with a machine).

Both Width and Depth.

I’m going to be using 3" tube, so I want to make sure those feet are as centered as possible on the platform.

Don’t know how wide your forklift forks can move apart. The base or footprint is 38" across the front and 39" front to back. Use 3 x 4 11ga tube for the forks. Let me know if I can help.

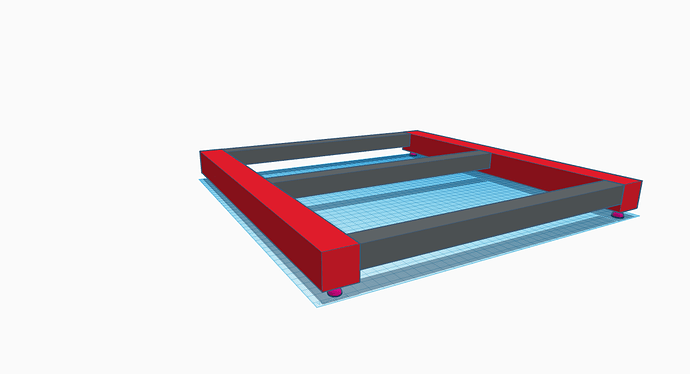

I’m going to use a pallet jack to move it, the design I’m thinking would look something like this.

The red tubes are 3" and run front to back. The machine will sit on the red tubes. The grey tubes are just supports for the pallet jack. I want to make sure I get the machine’s FEET on the center of those red tubes.

So you mentioned the base is 38 x 39 with it’s outside dimensions, but it would be great to know the dimensions of the feet, because I know those are inset a little bit.

I’ll get that for you . Be a little while.

35-7/8" across front from center of leveling bolt.

36-15/16 front to back from center of leveling bolt.

I’m going to weld this up and hold you accountable for those measurements!

jk. Much appreciated.

I would just wait for the leg kit. Set the machine on it and mark the holes. The leg kit is threaded 3/8-16.

I just ran 4" bolts up from bottom and threaded them into mount.

I like this idea a lot

Here’s my sled, designed for a pallet jack to slide under it. I put some big heavy padded leveling feet on it.

I don’t like how the machine is just sitting on top unsecured.

I’m thinking about welding the machine’s feet to the base, to avoid vibration resonance and sliding around when moving.

Just mark and drill, tap 3/8-16. Bolt it down. You may need some small 1/4 steel pads for it to rest on. Good job… looking great.

I’m not following how that would work. Wouldn’t the bolt just turn through the leveling kit and the steel base, if both are threaded?

Bring the bolt up though a hole in the base.

Thread it into the threads in the aluminum

Leg brackets. Or you can drill out the threads in the aluminum brackets and tap a hole in your base.

I see, so the bottom of your machine’s legs are mated firmly to your base yea? The bolt spins freely in your base and pulls the machine down. The machine is not sitting on the bolts (like they are with leveling feet).

Correct. I have nuts welded underneath and have screwed the base right down tight. The nuts you see are lock nuts to keeping them from coming loose.

@Bigdaddy2166 how much height did your skid add to the height of the machine?

4" inches to the total height.