Have you checked torch mount to slat bed level? Do you have a square?

Not sure why the link isn’t sharing, but if you scroll up on this thread you will see where Daniel posts a link on how to square up the torch mount assembly

Yes, that is what I meant by angle of the gantry. Sorry wrong term. My cuts are only angled along the y-axis. Did you notice the same thing?

With mine, the angularity was off on the whole cut. Have you checked that your cutting height on the gantry from + x and -x are good? You can do this by placing the gantry to the center of the table, with the torch all the way at -x, set the torch height with the 1/8” shim, then move the torch all the way +x, and see if your 1/8” shim fits the same.

Yeah I have checked that. In the last cut the angularity was off on all sides, but now after about 5 cuts my torch tip is going sideways again. I tried to run through everything before jumping on the forum. It just seems to cut so irregularly, one cut will cut all the way through, run the program again a few inches over and 1 out of three sides doesn’t cut through. But always with angled cuts.

And which tips are you using? Are you using the ones that came with the machine?

I bought a new set off of the langmuir website.

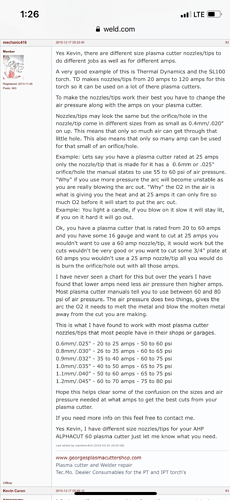

Alright well depending on what tip diameter those are, you could be blowing right thru them seeing as your cutting at 45 amps. If they are the .8 mm tips, they are only rated to about 35 amps where as 1.0mm is rated for 50 amps. Have u tried doin some cuts on 14g steel?

That is good to know, where are you getting your 1.0mm tips? I have cut quite a bit 20g and a little 14g. But this was all before the adjustments I did this morning. If you really look you can see some angle to the 14g cuts.

The tips I just got off eBay. Now I have yet to try them as I’ve just been cutting 14g and the .8 tips have been just fine. But as soon as I tried em on 1/8” aluminum, the tip was trash. So tonight I will try out the 1mm tips and see how they do

That write is great, thanks! I will be anxiously waiting to see how they do, if they work well do you mind posting the link to where you bought them? Are they S65 tips? I have a lot of 3/16" plate cutting work coming up so I am trying to get this thing dialed in before then.

Sure, here are the ones I bought

Cool, thanks! If your cuts go well later today I will def be ordering some

For sure! I will update once I use em

I bought the same tips and for me did not cut well I also noticed the orfice dia. is larger.

I noticed there are two styles. Did you order the drag tips or the pipe tips?

I ordered the drag tips (they look different then the tips that came with the plasma cutter, but idk what’s different about them besides that) I used the new tips to cut some 1/8” steel yesterday and they worked great, 0 issues so far. I need to try em on aluminum and see how they work

The only thing I can think of is they are made with the 0.6 gap built in? Did you still use the spacer when you set your z height?