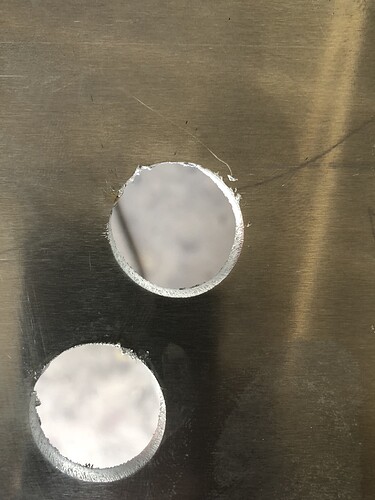

So I finally got the machine together and just made a simple test program to check everything out. I noticed on the circles, that near the top the cut is kind of at a angle (it may be hard to tell in the pics) but I thought it may be that the Teble is out of square but upon adjusting the casters, I did not notice any difference in torch to slat clearance. Is this a table issue or possibly a kerf issue?

Can you check how square the torch nozzle is to the slat bed? Sometimes the V block clamp will actually hold the torch at a slignt angle (especially the S45 torch).

Typically i just eyeball the squareness before cutting.

I checked that initially, I even unbolted the 2 Allen bolts, made sure the torch was strait and retightened, same result

If the torch is square to the material then the issue is within the torch. Try replacing the nozzle and cutting the part again.

Alright I will give that a shot. So you don’t think it’s a table level issue? I remember in the manual it states that circles will become oval if the table isn’t square

I dont believe that its a table issue. The circles you cut actually look pretty circular, its just that the edge angularity is not consistent. The two primary causes of this are:

- Torch not square to the slat bed (which you checked already)

- Nozzle worn/defective and is forming an assymetric air stream.

I have also seen this issue with moisture in the air line but it is much less common.

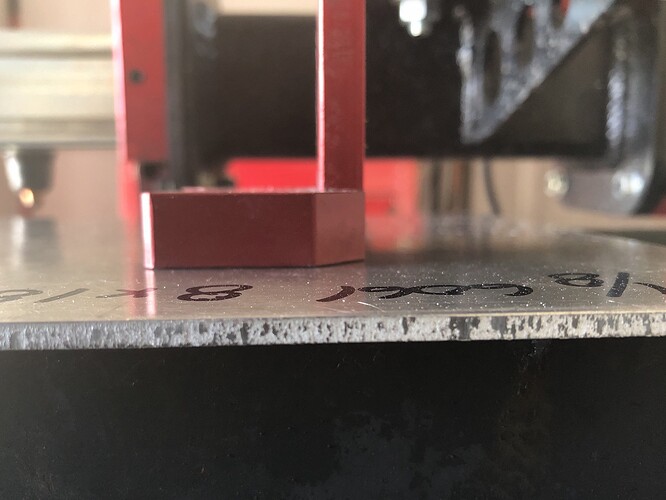

Alright I installed a brand new tip and the result is the same. I’m going to check my slat heights again and make sure it’s even across the table. Would putting a long level across all the slats be a good way to make sure it’s even? I did notice today though that I had the metal sheet on the table upside down from yesterday and the angularity issue is now on the bottom of the hole instead of the top, so that makes me wonder if it’s not the slats or the sheet of metal bending possibly as it does over hang the x fire table. (I do have a stand holding The over hang up though)

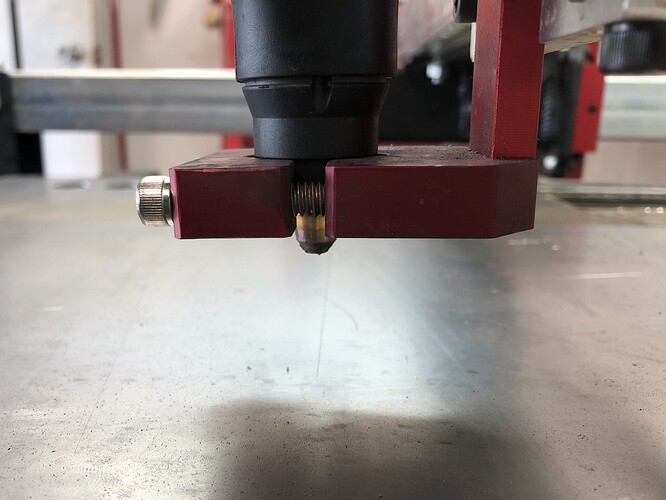

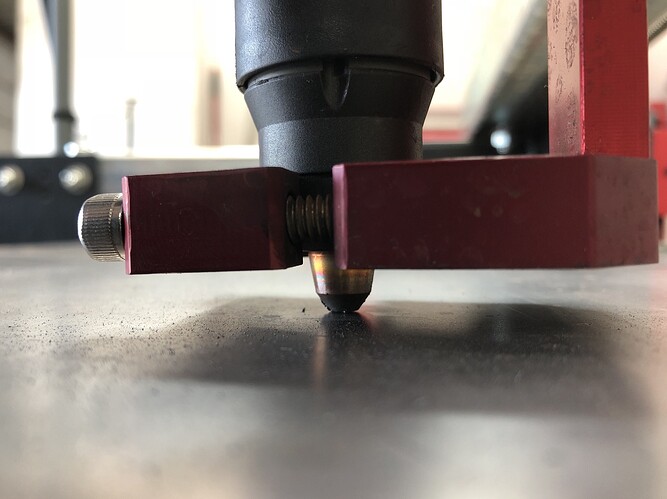

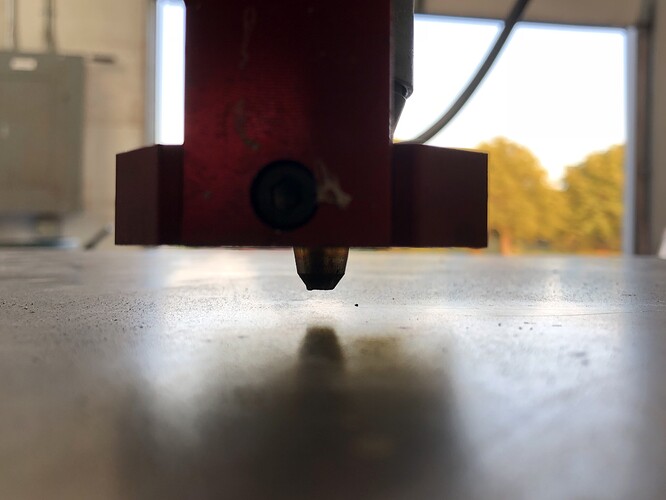

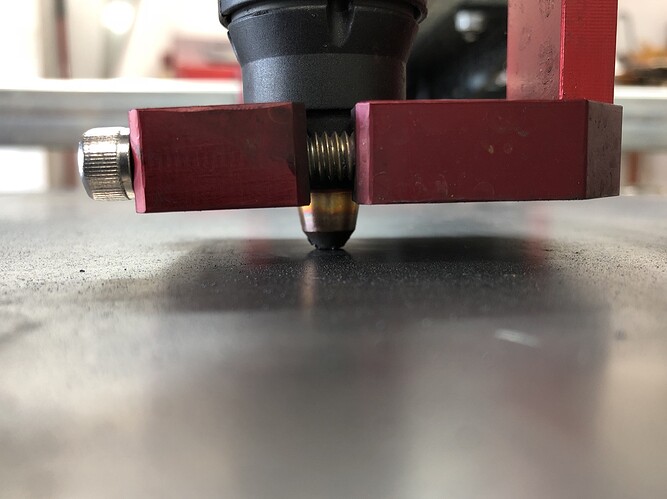

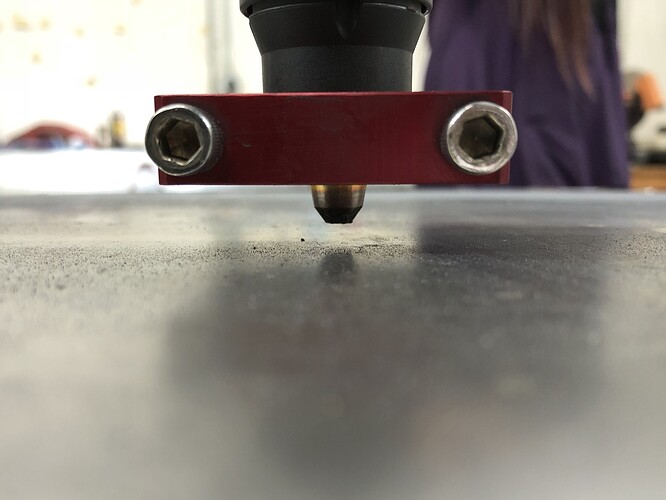

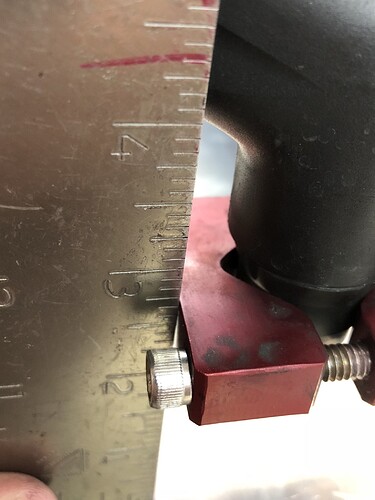

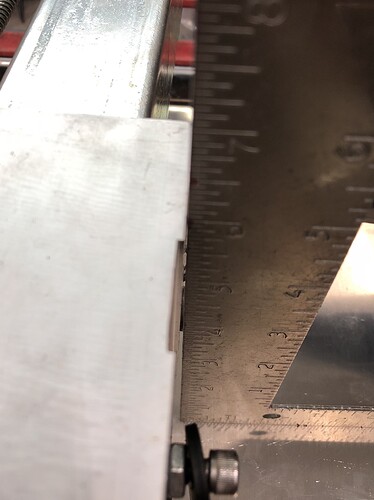

With the material on the slat bed, can you post a few pictures showing the angle of the torch to the material?

I typically prefer to hold onto the larger diameter of the torch cap that is adjacent to the diameter youre currently clamping to.

Can you check the squareness of the torch carriage to the slat bed using a square/protractor? See this thread for more info: Torch square to table adjustments

I tried again with the torch mounted like you stated, issue still exist. But taking a square to the torch definitely shows it not level, so that’s probably the issue.

Is the angularity consistent with the angles youre seeing in your parts?

In that thread i offered an explanation on how to correct the angle. Try that out and see if the edge angularity improves.

I will give that a try tomorrow, thanks for the help Daniel!

Can you send a picture of the nozzle that produced those cuts?