No I think the razor weld only has one tip.

Plasmadyne on eBay I think sells a kit for a smaller orifice size but they say it’s for “experienced” plasma people.

Razor weld only has one nozzle size or orifice size “one” kerf width.

jrmyers

February 24, 2022, 7:33pm

62

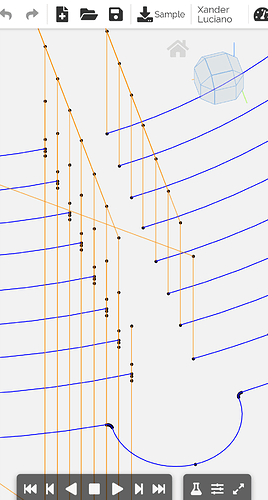

Good morning Tim, Running into an issue I’m stuck on. In the photos, there are irregulars as the torch starts off. Ive changed in my cuts the Pierse to 0 but I still get this. Any help?

jrmyers

February 24, 2022, 7:35pm

63

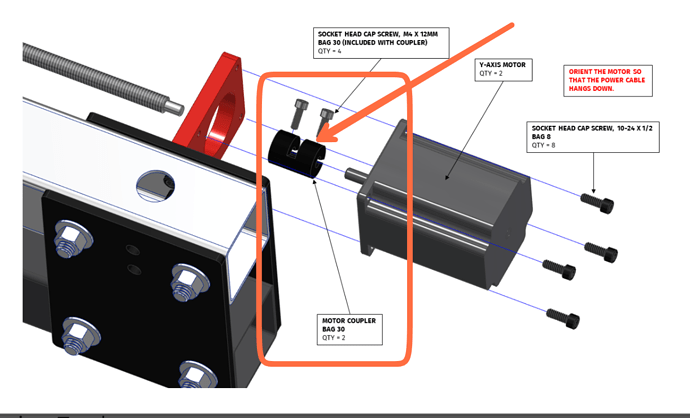

It looks like you might have some coupler slip or maybe some kind of binding happening.

Mark those couplers with a marker with a line from the shaft to the coupler and then run the break in program a few times see if they’re still aligned by the time you’re done.

1 Like

jrmyers

February 24, 2022, 7:40pm

65

Not sure what that means. Couplers?

There’s one attaching every motor to the lead screws.

jrmyers

February 26, 2022, 1:09am

67

Dang that was easy thanks

jrmyers

February 26, 2022, 7:50pm

68

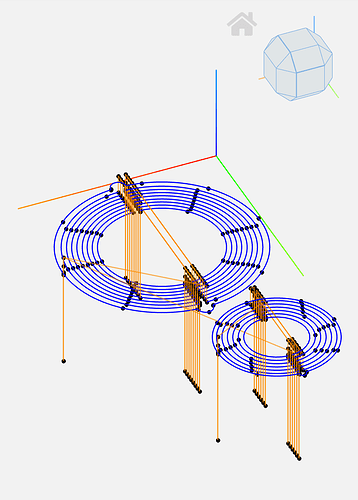

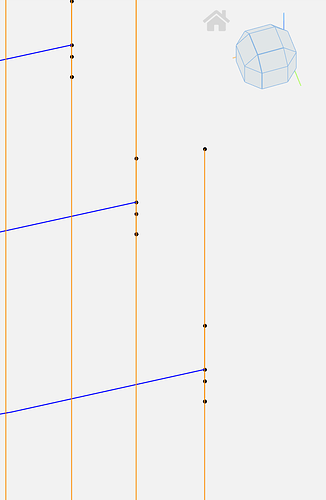

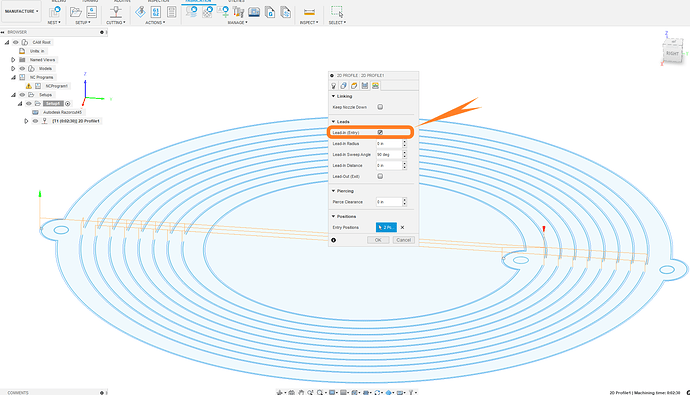

So at the end when the design is cut out, I get a little notch on the out side edge from the pierce. Is there away to alleviate that? I have my pierce set for 0 in the setup so the rings are all the same.

Pierce clearance to zero as well.

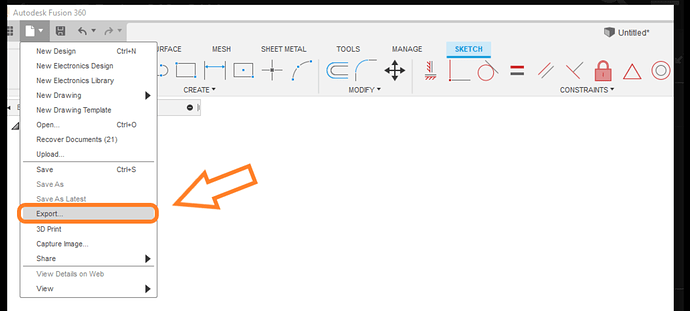

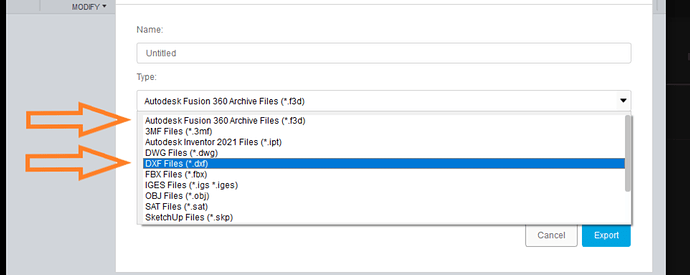

If you want to post your f3d file I can look through your fusion flow.

jrmyers

February 27, 2022, 8:50pm

70

See if you could post your f3d file it’ll have all the information included in your fusion 360 design

jrmyers

February 27, 2022, 10:40pm

72

Thanks I’ll fire up my desktop.

I looked through the NC file on my phone nothing popped out at me.

jrmyers

February 27, 2022, 10:45pm

74

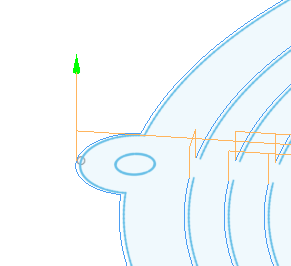

Im going to move the pierce on the outside cut out to the tip of one of the outer loops. that will allow for an easier grind down to get ride of it.

that file is not cutting out the holes?

you could uncheck lead-in entry but I see you did set it all to zero so it wont really make a difference.

since the first pierce delay is a little bit longer on fine piece I like to draw a line or circle to cut first then more to the finished work pierce

1 Like

Thanks. Went to start work this morning and the tip fell off and the ring it screws to shattered. Where can I get this replaced?

Bad slag build up and I dont know what this weird cut is from. The Y axis was acting up after continued use. Anythoughts?

I would pull out and an examine the new consumables.

So you have all new parts?

yes. new shield and cone (Hypertherm 45). New nozzle and electrode (Razorweld).

And you’re running all the same parameters as your previous cut? Where it was cutting not so bad except for the Pierce delays.