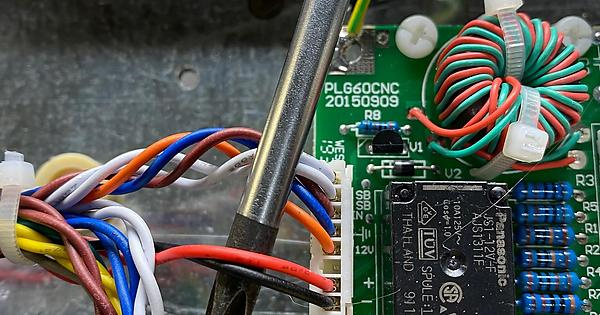

I had a very similar issue and what I found is that you cannot count on pins 5 and 7 on the back of the cutter. I was taking voltage readings at those pins and would get incorrect readings. I talked with Everlast’s tech support and they thought it might be bad CNC board, but I replaced it and nothing changed. I eventually tapped into the red and black wires shown below. When I checked the voltage at these wires I had the proper voltage (around 110v). Since I tapped in to those wires everything has been working great.

2 Likes