You can bet if you sell the refrigerated dryers you will need them. ![]()

Try running straight line test cut, pausing after about 3 inches. When cutting anything over 14ga I always zero my Springback, as it adds to your cut height. Especially running 1/4 in.

Hey everyone,

I’ve hit a roadblock with my CNC plasma cutter and could really use your expertise. Following recommendations from this forum, I’ve integrated a 1-gallon desiccant dryer and a Motorguard into my setup. However, I’m facing unexpected issues.

Equipment & Settings:

- Model: Everlast PowerPlasma 62i

- Amps: 51

- PSI: 75

- Cut Height: 0.04"

- IPM (Inches Per Minute): 45

- Nozzle Diameter: 1"

- Kerf Width: 0.039"

- Consumables: 1.0 tip (brand new tip and electrode sourced from https://poweredgecutter.com/)

Issue Encountered:

- The initial cut on a 1/4" plate was completed but resulted in a significantly wide bezel.

- Subsequent attempts (repeating the same program) failed to cut through the metal entirely, producing excessive dross on the top side.

- After about 8-10 pierces, the consumables were noticeably degraded.

Despite the addition of the desiccant dryer, which was supposed to mitigate moisture issues, the cutting performance has actually deteriorated. I’ve already ensured the torch is squared properly.

I’m at a loss for what might be causing this degradation in performance and consumable life. Could it be something other than moisture affecting the cuts? Any insights or suggestions would be greatly appreciated.

Thank you in advance for your help!

maybe I should try different pierce and cut heights?

What is your pierce height and delay?

Pierce height and cut height might be to blame.

I did not catch your pierce height but it should be 2.5x your cut height. If not, it is blowing all that metal back at the nozzle and electrode at close range while it is trying to pierce the metal. Consumables will be punished in that scenario.

Your cut height of 0.04" seems low. Was this determined by testing your actual cut height? Or by a chart?

I will back off since David is here…(He is good at this stuff!)

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P1.2

G0 Z0.04 (Cut Height)

Pierce delay .9

The cut height was lowered after using feeler gauges and learning that the .063 was too high.

I was also just thinking I cut at 51 amps and my 1.0 tip is rated for 41-50. Wonder if that could hurt it as well?

You can fix the cut height by eliminating or setting a negative value for the spring back in Fusion.

45 amps is plenty for cutting 1/4". My Everlast works best at 65 psi with the air flowing.

Ok, so I will:

- eliminate spring back

- set cut height to .063

- lower amps from 51 to 45

- new set of consumables

It sure looks like the work clamp is disconnected or has a connection problem. I agree with your new setting, but the old ones should have cut that without any problem.

Ok, so dropping the amps and air pressure from 51 to 45 and 75 to 65 resulted in it not cutting all the way through

- video: https://cdn.zappy.app/c366817cffbd63cb00ee781358ecf19d.MOV

- picture: https://cdn.zappy.app/2a0ad502591ba31302b932ace41dcd4a.jpg

So then I increased to 48 amps/75 psi and there’s less bevel (yay) but tons of dross and didn’t really cut the letters well

- video: https://cdn.zappy.app/77464a42d0a5c4fae3e929519a5f3e9c.MOV

- picture: https://cdn.zappy.app/3f4a29ea8ee7fac6f6c09b64ec0e8c17.jpg

My ground: https://cdn.zappy.app/98b63764740275224dc3e66120016d37.jpg

My consumables after only those two cuts: https://cdn.zappy.app/41d63fe320d5652ddecb065f600ba967.jpg

How about checking the other end of the work clamp lead? Have you tried a different file to cut?

Last week, we had a guy with the same problem, and his work lead had come loose at the machine bayonet plug. I’m guessing, but that setting should be cut without any problem. You can see that the plasma arc is blowing back into the tip and cup.

Good idea, I did move the plasma table off the ground up onto that shelf as part of installing the new gallon desiccant dryer, so maybe something happened there. I’ll check that first thing in the morning.

ahhhh it’s getting worse. Adjusted the ground, tried to cut and now it cuts and then stops and I get the torch moving before cutting speed error. I just tested THC and got a clean report

video: https://cdn.zappy.app/d2cabd1a2786d59793a0dc33cf5cd2d2.mp4

https://cdn.zappy.app/2599eeaf8c6ed424a432a19df99571a9.jpg

tried a new ground clamp which now allows it to run the full program but the cut quality is atrocious

video: https://cdn.zappy.app/70bf532e2800537de3bb24520fb156bd.mov

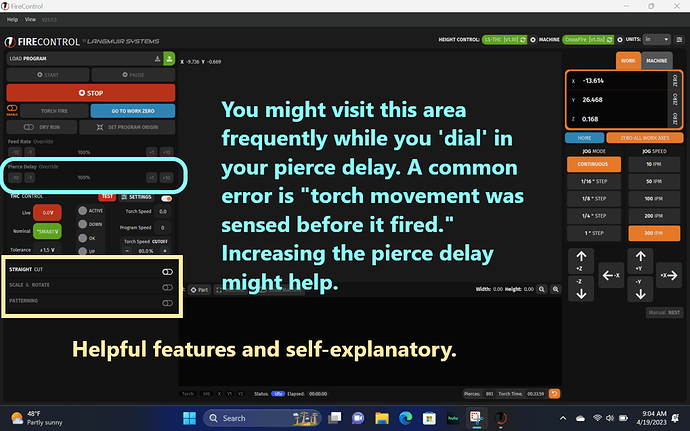

Increase your pierce delay. You can change that by adding to your current pierce delay just within your FireControl Screen. You can see that the first piercing of the small hole went fine because a longer pierce delay is created by FireControl. The second pierce lacked that “longer” delay.

As for the second issue with a different ground clamp: Yuck! That jaggedness suggests something with the lead screws.

- You might check to be sure the couplers are not slipping (put a mark on the coupler and lead screw with magic marker). See if there is any movement.

- Clean and lubricate the lead screws. (WD40 or silicone spray)

An interesting thing is that it appears you have little bevel now!

I’m betting you could hear the fluttering from the torch, while it was cutting.

When I had jagged cuts like that, it was plugged holes in the cap. With as melted as your cap looked, I’ll bet some of the holes are blocked.

Replace the cap and swirl ring, if you have spares.

I think you’re on to something there, ds690. I bet that is it.

He is also over heating the tip and electrode ( needs more post flow or not really getting the air to the torch correctly) and is still getting moisture in his air.