ok, i’m seeing that it’s not cutting completely along the x-axis and now I just noticed this line on the gantry tube, so I’m assuming something is too tight and is possibly causing it to not travel smoothly along the x axis https://cdn.zappy.app/178dd52307a4e58df10fc7ccfbaea8c2.jpg

That almost looks like a bad work clamp/ground positive not making good connection. And I did hear a noise when it stopped and restarted cutting on the right side. You may have a bearing going bad or something is way to tight and binding thing up.

I agree. Check the whole cable including the bayonet connector. Maybe even check inside the cutter itself for a bad connection or wire.

Ok, while I tinker with the ground, does this mean my stepper motor couplers are slipping? It’s not running the full x-axis and when I filmed in slow mo you can see it stuttering along the x-axis Screencast - 2024-03-18 - 0:15

Mark the coupler and the lead screw with a marker and see if it moves while you cut.

ok, couplers were slipping (thanks for the tape idea) so tightened those and it’s cutting again. Checked everything on the ground and couldn’t find the culprit and so put it all back together and it cut fine?

So not sure why the first cut was so weird.

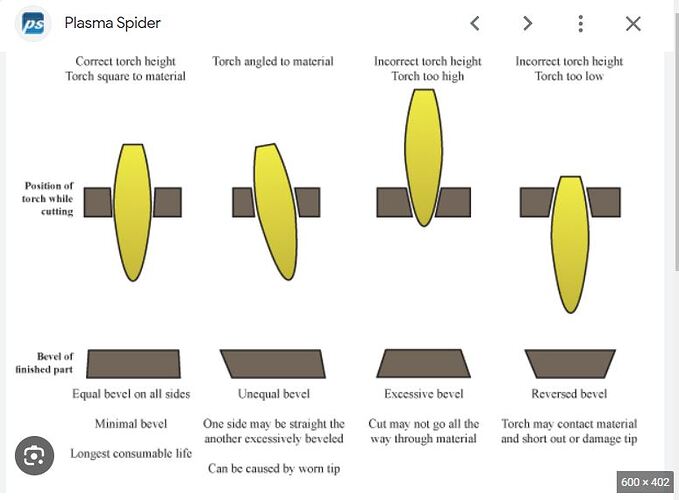

The bevel still exists so my guess is I’m still getting moisture in my air, which means the 1 gallon desiccant isn’t enough? Does that mean next steps are either aftercooler or refrigerated air dryer?

I use a refrigerated Ingersoll Rand cooler. Like has been said before having the molecular beads to close to the reefer unit discharge is no good either.

Yes you still getting some moisture, you can see it on the electrode.

A after cooler or refrigerated air dryer would be a very good thing.

Ok, i read quite a lengthy thread on aftercoolers that scared me (Air Compressor aftercooler Info thread - #84 by paticus) so was thinking of going the refrigerator air dryer route as it seems maybe simpler to install? My budget only allows for the harbor freight one and it seems like for some folks, it does the job?

Thanks again for the support

A lot of guys on this thread use the Harbour freight dryer. Remember, the cooler the air, the less moisture can be carried. Mine runs at about 34° discharge out of my dryer. Now, my compressor is 300’ from my molecular bead trap.

Indeed, the drying system you’ve created is quite impressive! However, it’s beyond my skill set, requires more space than I have available, and demands more time for implementation than I can afford. That’s why I was considering the Harbor Freight refrigerated air dryer as a more feasible solution for improving cut quality without facing these constraints.

that’s a great graphic on bevel, i’ll need to look at my parts more closely and see which one it is, thanks for sharing!

Keep in mind most refrigerated dryers have a recommended inlet temperature as well a desiccant dyers. I would recommend using a ir temp gun to get a idea what your system is doing.

I don’t have the space for a copper wall dryer so I installed a trans cooler with a fan after the tank before mr refrigerated dryer.

I agree; my machine is a screw compressor with a heat exchanger before the reefer unit. A reciprocated compressor will have much higher exit temps.

good to know, thanks for sharing, I have an IR temp gun, should I put it on the outlet?

I would check the temp coming out of the tank. @TinWhisperer shared a couple days ago desiccant beads can work around 150 they work best between 70 and 90 degree. Best I can remember the numbers. I have a trans cooler with a hv fan that cools my tank outlet. I do long runs sometimes 2 to 3 hours of constant air use my refrigerated dryer never sees temps higher than 70 degrees.

With that said checking metal fittings will get you a good idea I have to assume the actual air temp is a little higher.

The refrigerated dryer are great if you don’t plan on cutting a lot you may get by with some sort of after cooler. I added one piece at a time.

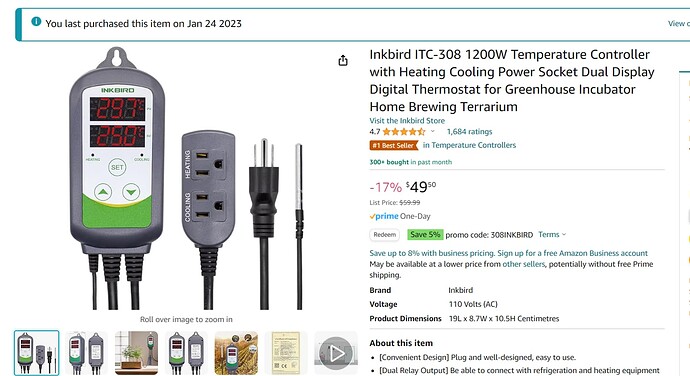

this is a great device to have in the shop…the sensor is real accurate and is handy to have.

I have a couple of them…one is attached to mt copper cooler that turns a fan on and off to cool the copper.

I have another tied into my flooe heating system in the concrete to turn it on and off…

you can use one for a emergency shop heater in case it drop to low it comes on and alarms…

so it would be great to use as an accurate temp reading device…for air temp on pipes…

the problem with the IR guns is they are not very point accurate…

you do not have to use copper…

you can use PEX wich anyone can do…cut and crimp for real low cost…just use 3/4’ pex

as for space you can even mount this on the ceiling if you want…just give it a small slope to drain the water to an outlet…

there are soo many options…

just some ideas…

Great, I’ll go ahead and get one of those sensors.

Considering I’m in central Texas and my workshop is in a shed without insulation, it’s pretty much guaranteed that my compressor will both produce and intake hot air.

From what I understand, the solution to my issue isn’t choosing between an aftercooler or a refrigerated air dryer; instead, I likely need to use both.