Mostly 14g. I do have some 1/4" and 1/2"

here ya go. 14 ga 90 ipm. try 35 amps.

1.5 circle with .5 hole

14 ga test.tap (964 Bytes)

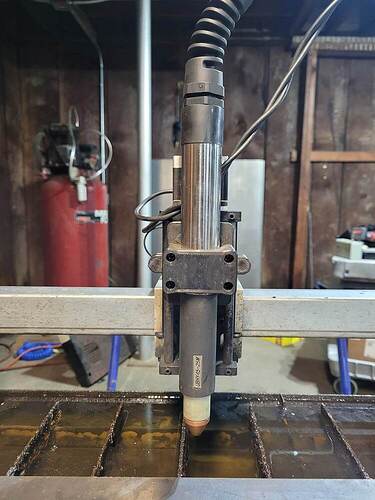

Thanks, i’ll give a shot here in a bit. Here are some pictures of how the cables and torch are set in the holder. Excuse the dirty shop, still waiting for the walls to be completed and whatnot. Using this time to try and get my machine hopefully dialed in.

Here are some photos, of the dross from cutting yesterday. The cuts with less dross were some of my first cuts, and were below 60 IPM if I remember correctly. If I have to cut 14g at 60 IPM i’ll throw the plasma cutter away haha.

I think I forgot to mention that recently I had to remove the aftercooler setup on my compressor, it developed a leak after moving it the other day (my fault).

Is there a simple way to check for moisture in the air, I know there is the mirror trick, which I havent tried recently.

you have not seen my garage. do you run a bead cell dryer? the rw45 isn’t the best but not a bad plasma. give that a shot you may have consumable or air issues. if need be, you can call me sometime i could help you from square one. I am by far an expert you have something not right but not a lot.

I do not have a bead cell dryer.

I have a Harbor freight air dryer, DeVilbiss QC3 filter/ dryer and a motor guard M-60.

i would recommend one for sure you will be surprised by how much moisture is left in your air. have you considered voltage drop as well?

some of your cuts dont look to bad.

Is there a specific one you would suggest? When I first started I used a harbor freight one to get me started, but was constantly drying you the desiccant beads.

I haven’t considered that, I suppose I could look into that as well.

I can agree with you there, but they were definitely very inconsistent. I should be heading to my shop shortly to try out that file you sent over.

as long as you have a quart or so. your air dryer will catch a lot. but there is still moisture in the air that will trash consumables.

i will be in the garage half the night if i can help in any way.

Thanks! I’ll reach out if needed!

Is your plasma cutter next to table controller, if so, move it you can be getting Emi.

I did recently move it closer to the controller, ill try and move it further away to see if it changes anything. I had it further away at one point with extended cables, which I removed for troubleshooting purposes hence why its closer.

according to picture it shouldn’t be a problem. you have an older plasma that mine looks like.

Cut out some of the future washers haha. I didnt notice any difference in dross and paused during the cut height was definitely close to .1". Amperage had no effect on dross, nor did playing with THC settings.

From there I increased the amperage to 45 and the speed up to the 170 IPM and had almost no dross except were the lead in was really.

I performed the line cut from last night at 45 amps and had the program sped up to a max of 200 IPM, (160%. Increase). The last few lines had almost no dross except near the start and finish.

Are those settings I should live with?

I tried lower amperage and lower speed, like 25 amps and 70 ipm and still had dross.

maybe all plasmas are different. it may be your limit as long as those setting work for 14 ga roll with it.

curious to see how it looks cutting out an actual part though.

how old is your plasma?

that program had a path rule to gear down and cut hole at 50 percent

Seems like the z-axis cradle is sitting way up high

Looks like you have very little upwards z travel

did you check to make sure you was touching metal before ihs switch trips?

I’m honeslty not sure, i didnt originally purchase it. But most of what I cut is artwork. Ive been running it at 165 ipm. I might rip a big piece on this last bit of hr 14 gauge and bump up the setting and see how it does.

it is still cutting high though. if it hits material about the time the ihs switch trips it could make torch bob when you hit high and low places. if the switch trips in a low spot it will automatically raise to a cut height.