Thanks man!

Wow that’s pretty cool nice job!

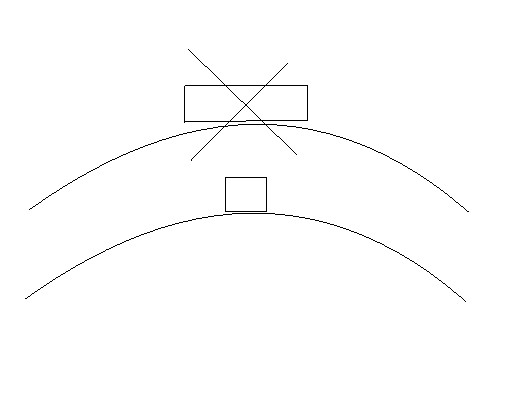

One of the common missuses of a magnet is placing it the wrong direction. If you place the magnet across the curve of metal it will fall off.

I had mine like shown in the lower drawing but still fell off on 1/8" and 14ga, 3/16" it was fine.

Somewhat off topic, but related… I’ve been trying to figure out how to handle larger pieces of thicker plate that I can’t handle by hand. For me this includes getting them home and in the garage AND then on the table.

What do you guys with smaller home shops do to get your material from the supplier home into your shop?

I can fit 4ft wide sheets in the pickup bed. At home I back the truck up to the garage and use roller stands to slide the pieces off - either onto the Crossfire or onto a tilt table (from Harbor Freight if I recall) if I’m going to be stacking it against the wall.

Some folks are using overhead winches & magnets - there are several posts for those. I’m going to do the same in my new shop as I build it out.

I have a small garage…so I bought a collapsible motor hoist…mounted 4 full rotation wheels…and extended the reach a bit…

I have a plate clamp on it…I cut the sheets down to 4x4 when I get home and move them around with

“My little Crane”