Purchased the Crossfire Pro late last year and have been steadily modifying; adding guards, LS kit, rolling stand, & etc. (mostly sourced from this forum). Looking for methods or ideas of loading full - half sheets of 1/4" or 3/8" plate and was wondering how everyone else is doing it? . Recently, just completed a rolling stand and had the idea of an integrated scissor lift to help achieve the task but would like to source the forum first. Any tips or ideas you all may have would be greatly appreciated.

I have a small overhead beam with a trolley conveniently right at my table. I bought a lifting magnet off eBay. I would assume you could use a cherry picker ( engine hoist).

That’s a great idea, I’ve been in the market for an engine hoist and have been looking at the HF 2 ton engine lift (waiting for it to go on sale). What capacity lifting magnet did you go with?

I have two one is a 800ish and I is a 1500. I also made a lifting bracket so I can use both at the same time or just single. I have seen a few with the hf gantry system pretty sweet idea if you have the coin and the room.

I regularly lift 1/4 inch full sheets. Also I have done quarter sheets of 1/2.

Here is my setup, electric hoist from Harbor Crap, 1400-pound capacity on/off magnet .Installed 3/8" x 4" x 20’ I-beam when I built my shop. Works great.

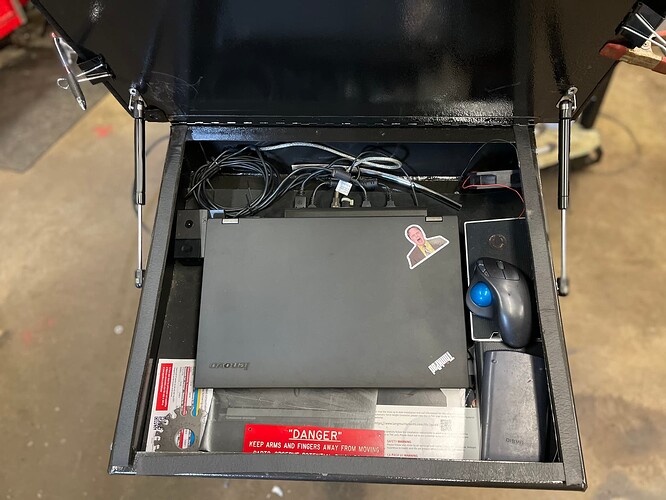

Could we get a few more pic of Laptop stand? I like it.

Nice setup sir, looks similar to what Phillipw has described earlier. How does the magnet do if you wanted to set sheets upright for storage; would it break away easily? Would it be possible to stack lets say a 4ft x 4ft sheet of 1/4" plt without testing out the steel toe boots?

I also have a lifting magnet. Works well. I also have a 6” deep wide flange beam that is 20’ long I am planing to mount to rollers that will attach to the steel pipe trusses. I am working on gathering the parts. Then all I will need is the time to install. I got the wide flange beam free from a previous employer when i was in college.

I did a truss analysis and they can support the Max hoist capacity with a little wiggle room. I may have to use some discretion on loading it up when there is snow on the roof.

Yes sir, here a few more pictures. The majority of the pieces are 14 ga. mild steel. Once I clean up my sketches, I plan on putting the dxf’s on fireshare.

[Processing: IMG_1415.jpg…]ty

the lifting magnets need to pull straight as for as using to stand metal upright i don’t see happening. They can break away easy for sure don’t get under it. i do stack metal on top of each other. steel toes definitely a plus.

Here is the magnet I am using. I was skeptical but so far it has been Working for me. I haven’t tested it’s limits yet. And I defiantly keep all my digits out from underneath the suspended load. ![]()

On my pro i intend on using the open space on the rear where the rail extend past the pan to create a support structure for the sheet to rest on.I contemplated something with rollers or just a another rail going across for it to rest on.A 4x5 sheet wants to bow when you push it all the way back as of now.

I have 4 of the hf roller stands works great.

That’s a serious movable platform you made to put the table on! Is that 1/4 plate?

I have picked up 1/2" x48" x 60" steel plate on edge with magnet to stack against wall. Layed flat on floor moved magnet to top edge and picked up to lean up against wall. I Would never move sheet around shop by edge though.

I personally lift with my back and not my legs every time. Also I try to make sure the floors wet so I can have a near death experience while doing it lol.

Lol Currently my method, don’t forget the twisting jerking motion as all the weight is transferred to your back. Helps the momentum.

Ahh yes of course I almost forgot the ol’ whip and rip my back maneuver lol

Yes sir, i’d plan to lift the sheet center of mass then offset to set the sheet to stand it up. Looks like i’m in the market for one of these magnets.

The frame is 2 x 1 x 3/16 bar channel then I used 1/4" plate to make the cradles where the pro’s feet rest. Attached is a couple pdfs for the rolling assy.

Overall Assy…pdf (322.5 KB)

Rolling Assy…pdf (300.7 KB)