Magnets work great. They are like a strange dog and ( well my wife). Never trust them!

I pre-cut the 4x8 sheets in 1/3s. 1/8” and thinner I just lift by hand, anything thicker is a lifting magnet and shop crane.

That’s impressive. The supports slide out to support material correct?

this is what I made to lift metal. I made it from scrape steel from the scrape yard. Used 6" wheel and with the wheels it cost about $200 for the materials.

I married well. 10ga 4x8 is the largest I have cut though. Will use the skid steer and fork for anything much thicker.

That’s a lot of steel for $200!

The 6" steel wheels was the biggest cost, the steel for the structure was only a little over $100. The scrap yard I go to only charges about 20 cents a pound and the guy always knocks the weight down.

That was the plan but did not end up building it, so I can’t speak on the performance. My thoughts is that it would support (at a maximum) the hangover of a 4’ x 5’ sheet of 10 ga. and 4’ x 4’ of 1/4" plate. Also, with use of magnets on the pads to anchor thinner material to prevent it from walking around on the material.

I have the same 800 lb magnet, I have just one. It worked good on 4x8 3/16" in the center, but nothing thinner. 14ga it wont pick up and 1/8" it picked up but fell when it swung a little bit. So I will get a 2nd one that should fix that.

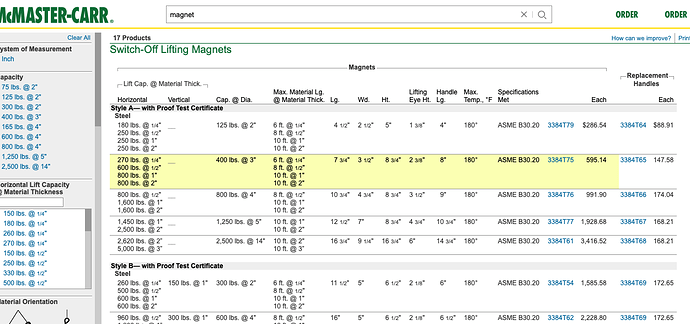

Magnets are ok for flat pics for loading the table however LOAD RATINGS should be looked at carefully. The flex of the plate changes everything. Get the manufacture specs per the plate thickness. load ratings is dependent upon the thickness. NOT rated for picking up more then a single sheet at a time either. We have magnets at my work and I see people drop stuff often. Most industrial sites won’t allow them. Everyone on this site would be better off with clam shell style plate clamps for picking flat. That’s my opinion and I understand that. Here is the specs McMaster gives on some of their magnets for reference. You can see you have less capacity with thinner plate as it will flex more and cause it to pull off the magnet clamp.

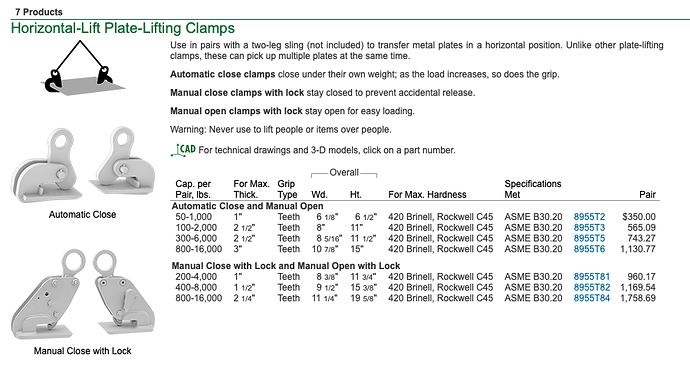

Here is a better option since I am being mr saftey today lol.

also here is best option for lifting vertical

Do you see people having trouble when using two magnets? I just ordered a 2nd one ![]()

Do you think most places wont allow them because people are careless?

Some times no matter how safe they make something there are people that can easily out smart that safety item/device and can still have a accident! ![]()

Thanks for the input good to know.

You would need a spreader bar so that the the force is straight up. Any side pull will put flex into the plate increasing risk of dropping. I wouldn’t recommend it. It might work 100 times perfectly but the one time it doesn’t will cost you bent material at the least. As previously mentioned never trust them.

these magnets work best lifting straight up i make a lifting bracket so both magnets are pulling straight

you beat me to it

I was going to use a spreader bar. I will have to do some more research and make a decision.

Thanks for posting

The magnets work just fine, when used as intended. I haven’t had any 14- or 16-gauge sheets of steel fall yet from magnet.

Are you lifting full sheets? if so are you using one magnet?

I cant lift full sheets any thinner the 3/16" with one magnet

Yes, I lift full sheets. No oil or rust on sheets.

That’s legit sir!