I’ve been looking at the two main options for air dryers for the plasma table… the Harbor Freight Air Dryer system or a set of wall-mounted copper lines.

For pure simplicity, I am tempted to go with the wall mounted copper line setup. No moving parts, no electricity, and if properly designed… should cool air well enough to condense all water vapor.

The $64,000 question is: How much surface area is required to effectively cool with copper lines?

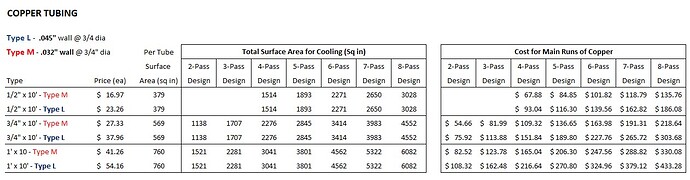

I did a quick 15-minute analysis of available materials and looked at the systems people have posted on YouTube for reference and came up with the following chart.

A lot of guys seem to use simple 1/2" pipe with around 6 passes which works out to around 2271 sq in of cooling surface area. I put larger diameter options in the table just to see how the overall surface area compares, but also to see if using fewer, large diameter copper tubes was actually more cost-effective, or if it all works out the same.

As it turns out: A 6-pass 1/2" system equals a 4-pass 3/4" system equals a 3-pass 1" system… each offers around ~2200 sq in of cooling surface area.

Didn’t bother to price out couplers, reducers or ball valves yet… this initial table is really just to figure out what sort of surface area target makes sense.

The larger diameter tube can definitely match the overall cooling effect (with fewer pipes) of a large 1/2 copper tube cooling system. The added benefits are slower air velocity which should aid in water removal effectiveness, and a bit of extra air volume to store air (though probably negligible). Downsides are certainly that the fittings will all be more expensive for large diameter pipe, but fewer will be needed to build an equivalent system.

Pricing is just today’s Home Depot price list applied for the various grades of copper pipe (L vs. M) and with different diameters.

Feel free to add commentary and opinions. I haven’t bought any materials yet… but was just doing some research before heading to the store later on this week.

Thanks!

-TM