It’s not that I am uncomfortable doing it, I was just wondering if they were willing to say the warrantly would not be void if I did. I still have 8 months on my 3 yr warranty, so I was hoping to keep that.

Primeweld is good about this. Just give them a call tomorrow at 856-537-4368 and ask. Bet they say its fine.

Thank you for your help!

While I still haven’t hooked mine up, I did call Primeweld today. You are right. The said this would not affect my warranty if I made direct raw voltage connections. They also said that “only about 6 customers have reported the issue” caused by going directly through the CNC port.

My question is, do I still use the wires that came with the unit if I connect directly to the raw voltage internally? They look like somewhere around 20 gauge wires. Is that okay for this application?

BTW, I am leaning towards using the CNC port because my Cut 60 is over 2 yrs old and I also read it is the more recently purchased units that are the source of the failures.

yes you would use the wires that come with the table.

I would just hook it to RAV and be done with it.

Thanks for the advice. You and others here have way more knowledge on this subject than I do, so I will go ahead with the direct connect method recommendations.

Great members create great forums. Thanks guys!

I had an issue with the VIM Module and Div voltage.

The way I resolved it was to use Pins 5 and 7 which are the Raw voltage running through 100K resisters It lowers the voltage some.

The table controller seem happy with this set up.

I am now in the process of dialing in the THC setting to get the proper torch performance.

After talking to Primeweld, I took your advice and wired it directly to raw voltage. I haven’t fired it yet. Been fixing a leak in my water tray. Thought I’d show a pic here ( I posted in the “Build” thread) of what I thought was a good idea: I used some auto door bumper grommets for my pass through protection.

hope it works for you…on its own, the primeweld is great, and offers an option that doesnt cost $2000+

It’s a bummer to see the issues with these, I ordered mine in August and it sat while I waited for my table and now while I wait for my shop to be built.

I bought it specifically because I wouldn’t have to open it, and now I have to open it lol.

No huge deal, but disappointing.

I’ve seen on Facebook there’s a torch for these that takes Hyperthem consumables? Can anyone shed some light on that?

See this thread- https://forum.langmuirsystems.com/t/crossfire-pro-primeweld-cut-60/17468

It is possible that folks who have issues using the divided voltage output on the CNC connector do not have it wired correctly.

(See the video referenced in that thread).

I have a Crossfire and Prime Cut 60 that has not been up dated. I had the issue of excessive voltage on the Div port also.

The way I solved the issue is to wire the CNC Plug to supply the Raw Voltage protected by 100K resisters. This allowed the use of the raw voltage inputs on the VIM box… The resting voltage I have is .3 volts, The test voltage is 70+ volts and on 18 Gage sheet metal it is 54-56 volts.

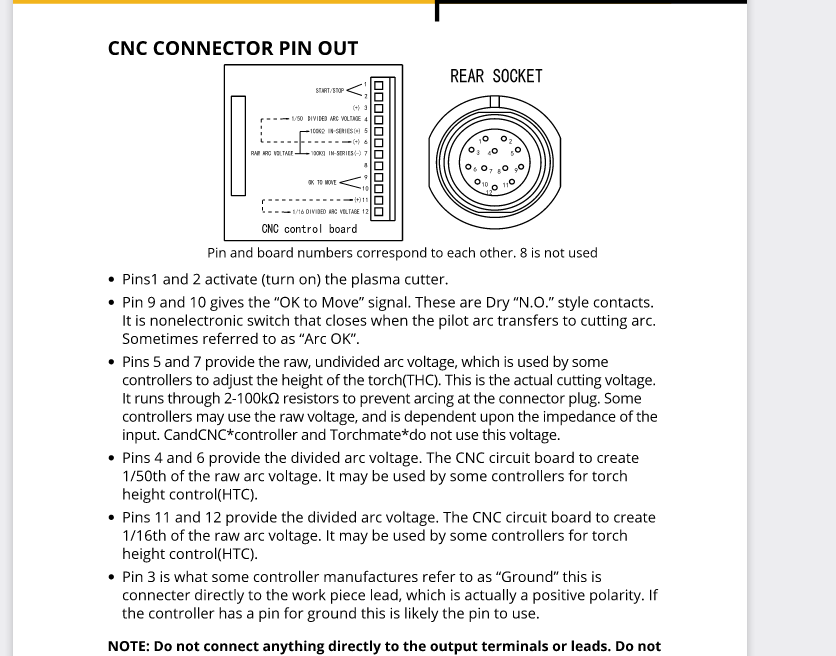

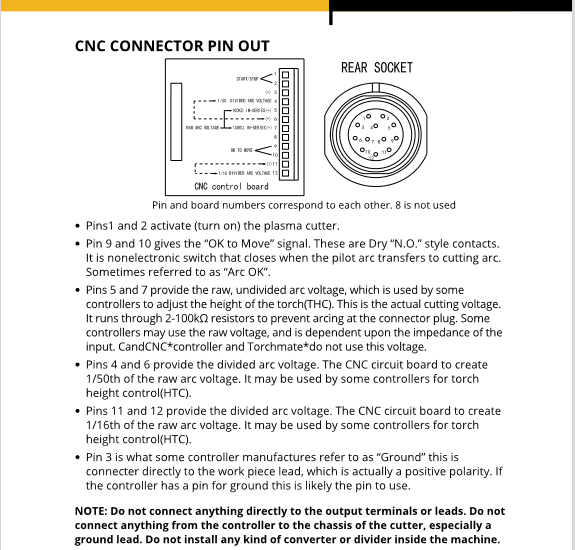

The issue that took me the most time was figuring out that on the thin stuff I needed a test cut to get the target voltage because the Smart voltage won’t work . Once that was done the THC operates well. Here is the Connector Pin out so you can find the raw voltage Pins 5 and 7. Remember 5 is the plus voltage and 7 is the negative, this is important.

Hope this helps