I tried a first cut on a used Crossfire Pro (with THC).

The first object, a circle, cut beautifully, when the torch moved to the second object it didn’t fire and threw a ‘Torch Moving Before Cutting Voltage Sensed’ error. I tried again with the same error.

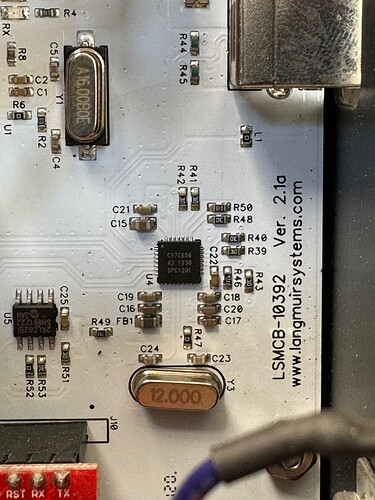

After some reading it seems my Crossfire may be an early edition with an L1 circuit problem.

Could somebody confirm from the image? and whether the error is consistent with the circuit board issue?

Thanks

If you can solder, remove the resistor and solder a bridge across the board. It acts like an antenna for EMI interference. That will fix it. Now, that may or may not be your problem. It certainly won’t hurt to eliminate that issue.

OK thanks - I’ll try that

You have to remove the resistor first. Just to be precise. Email Langmuir. They may give you an updated board—just a thought.

I soldered the board, I think it’s OK. Unfortunately I still have the same error, the first piece on a job is cut really well, then it moves to the next part of the sheet and just doesn’t fire. ‘Torch Moving Before Cutting Voltage Sensed’ error appears.

I’m clamping directly onto the workpiece and have changed my pierce delay times from 0.1, 0.5 and 0.9 seconds with no luck.

Plunge rate 60 or even faster, 75, 100 ipm? Laptop? Is it plugged into the wall outlet? What are you cutting? How thick? Fusion or SheetCam?

Increase your pierce delay .2 sec

There was just a thread where someone had changed their pierce delay all over the place with not changes. Pretty sure it ended up being plunge rate for them. So @Bigdaddy2166 is probably right on it.

I don’t remember plunge rate being such a topic years ago. I wonder if something changed somewhere as a default or in some initial instructions?

I believe this might be the previous conversation you are referencing:

It was not confirmed what error message that user was having. Several of us suspected that he was successful avoiding the error message by having a really slow plunge rate and a short pierce delay. Most of us were under the impression that his pierce delay was far too short.

If @clio has tried 0.9 seconds and it did not change it, he might also consider air pressure. Perhaps the plasma cutter is not firing at all.

Increase the plunge rate to at least 60 IPM or more.

10 IPM is way too slow. Maybe even 100ipm

I did read about the plunge rate. I am using Fusion though and I could not work out for the life of me where this could be adjusted. Scratch head.

I agree! I believe it is set by default in Fusion 360 to something like 100 IPM. It cannot be adjusted with plasma cutting tool path as far as I can tell.

Z-Speed Factor

The Z-Speed Factor setting is used to tune the Z-axis travel speed when the THC module is in control. The Z-Speed Factor is used to set the real-time Z-axis travel speed as a percentage of the real-time XY travel speed. This makes it so that the Z-axis motor can move faster when the XY speed is faster, but also slow down when the XY speed gets slower such as around tight corners or small holes. This feature allows the torch to react to sudden changes in plate height when moving quickly, but also prevents the torch from plunging downward when the torch speed slows down. The Z-Speed Factor sets the Z-axis speed based on a percentage of the current XY speed. For example, if the Z-Speed Factor is set to 10% and the live XY speed at some point during a cut is 100 IPM, then the Z-axis speed at that point in time would be 10% of 100 IPM or 10 IPM. If your plate is especially warped, you may need to increase the Z-Speed Factor so that the Z-axis motor can move quickly enough to keep up with large changes in plate height. For most cutting needs, the default setting of 5% will be sufficient. For example, a 5% Z-Speed Factor can correct up to 4" out of flat over 48".

The max Z-Axis travel speed under THC control is 60IPM; if the calculated speed exceeds 60IPM then 60IPM will be used.

The Z-Speed Factor can be set anywhere between 1 to 99%. The default setting is 5%.

This gets set in fireControl THC setting. Z speed example. your cut speed is 100ipm. If you set the Z speed at 10%, it would be 10ipm. If you set it to 65% it would be 65 ipm,

But THC is not involved with the initial plunge going from pierce to cut height.

That’s how I adjusted it. It seems to work. Maybe some of our Fusion rocket scientists could chime in?