The only reason I question the software part is that it does it on the cut file provided by Langmuir. If it worked fine on that one then I’d tend to agree.

I could be wrong. If that is the program on the screen in the picture. If you look at the left side it has 5 points and straight lines between them. That is how it will cut the computer will only do what it is told to do.

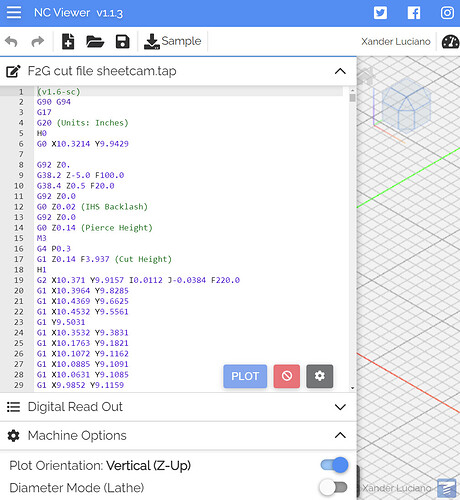

@ScottNH cut height seems off in your TAP file.

@DRwelding whish version of firecontrol are you running?

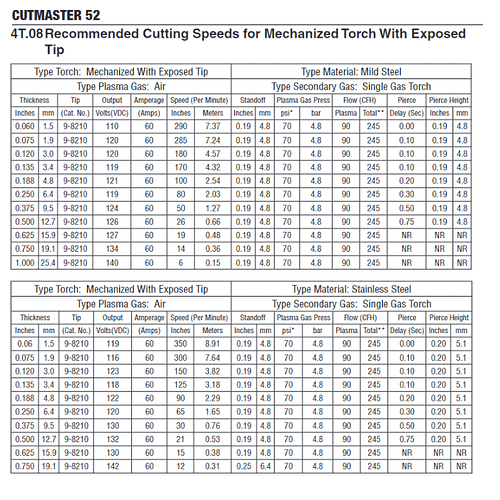

I think some ESAB consumables also have a similar cut height.

Fire control 21.1 I believe. I just got the machine 2 months ago

@mechanic416 seems crazy but…

here is a ESAB CUTMASTER 52i cut chart screen shot.

it is even higher at .19

That was my first thought as well. I thought he had pierce height mixed up with cut height.

Even started to respond that his cut height was too high. Then I went and borrowed the manual from the internet (AKA @TinWhisperer ) and deleted everything I had written before I posted it.

firecontrol seems to just display arcs like that. It caught me off guard the other day and I had to check my file. But it cut smooth.

I produced a nc file from the F3D i linked you and it looks smooth in a NC viewer.

fram to glass forum example .nc (102.0 KB)

@DRwelding in the video it runs smoother counter clockwise then clockwise

I have seen on the forum and in my own experience that the visualizer my appear faceted but will cut smooth @brownfox lol I was just in the middle of typing that.

Could this be a power issue when all the motors are operating?

It wouldn’t make sense for it to happen in one direction of an arc and not the other though… maybe?

it doesn’t but watch the video it sure seems to be the case.

- edit I just watched in again it runs smooth counter clockwise and shaky running clockwise.

OP - plug this svg into your sheet cam and process it using your settings and see what happens. Do 1:1 import ratio at 96 DPI. If this cuts shaky, I’ll post it with my sheet cam settings.

This was done in affinity designer and there are only a couple nodes.

looks like .14 in NCViewer which is what the chart in the Hyperterm manual says. What am I missing Tin?

You’re not missing anything, it’s me having a mental lapse.

I was reading the number beside it.

I never gave it any though before So I went to the shop and did a measurement on the drag shield for a Hypertherm 85 and a Thermal Dynamics 82 and they were close. Well those are the right cut height’s on both charts. They just look way to high to me, that is a long way to stretch an arc.

LOL I wish that never happened to me…

Ok I’ll give it a try tomorrow hopefully thanks.

Update. So after talking to Langmuir, they checked over the file and told me that I need to convert the line segments into splines while it’s still in Inkscape to reduce nodes so the machine reads them as smooth curves instead of line segments. I was unable to take great notes when I spoke to them so I’m paraphrasing from memory. I’m going to mess around with that for now and explore. They said the file ran funky on their machine too so that rules out mechanical issues. Does this sound familiar to any of you?

How does that expalin the file that Cameron sent you not cutting correctly?

For the file sent you I used smoothing ( @ .004 ) in fusion which reduces the overall g code and smooths out the nodes

I have been running smoothing at .004 on my other cuts and still been getting the glitchy cuts. I’m too new to the software to have any good quick answers, arguments, ideas. I do feel like they are trying to help but i am very surprised to apparently be the only person with this problem. I’m willing to look everywhere but I’m wasting so much time. Thanks again for all the info and time.