thank you for taking time to do that. i watched the video. im making some tweaks now.

did you try the file Tin touched up?

FBc wheel fusion fusion file tin forum twtich stream v1.f3d (2.6 MB)

not sure how much difference it will make but your refrigerated drier should be right off the compressor.

is this a dessicant type?

no dessicant, i havent gotten to the touched up one yet. i should be able to tomorrow. the air dryer is about 8’ away from the compressor due to my tiny shop.

ill give an update soon!

cheers!

May want to add an aftercooler to the compressor. If you’re supplying the air dryer that soon in your line, it’s probably not working as efficiently as it could. I believe they recommend a decent amount of line separating it from the compressor.

I have some hoses that would probably fit right on your compressor to pipe the aftercooler super easy without having to run any copper pipe or anything. My compressor is an IR 60 gal so I’m pretty sure the pump and tank fittings are the same.

I need to start an affinity twitch stream. I have a way that I simulate the kerf width while I’m designing to make sure everything fits before post processing.

Also, the sync cartridges are supposed to have a crazy small kerf. I cut with hypertherm fine cuts on 16 gauge with my 45xp with book specs.

However, I also have a rule set in sheetcam that I tweaked until I got optimal results every time.

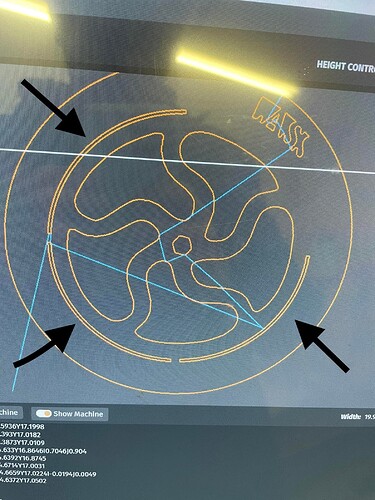

So this is a great representation of what is causing the main issue. When cutting radius’ when the machine travels in one direction it is butter smooth. When traveling in the opposite direction it glitches hard. The machine is jogging great and all axis are tight no slop. This is getting pretty crappy. Here is a photo showing the three radius cutouts and a video of the malfunction.

youtube video of glitch

Video did not work for me. So straight line cuts are fine?

yeah it will run one side of the radius smooth as butter, when it gets to the opposite side it glitches and does these micro pauses. i wish i could get the video to work.

i posted a link to the video above on youtube.

Wow that is not smooth for sure. So lets talk straight line for a min. If you run the X axis in both directions does it work ok? How about Y in both directions?

My thinking would be, if the above works ok then its not mechanical.

Straight line x and y is what I would consider perfect for this machine. And as the video shows, some radius’ turn out perfect it’s alway the flip side of the radius that glitches out. It’s really Wierd. I really took a lot of time and care to tune this thing in. At my job I deal with complex automated machines so I am pretty good with getting things to the correct parameters. I want to say it’s something in fusion or post process but I have tried a lot of different parameters as this point and no luck.

That still sounds like extra nodes in the design to me. Can you post that file?

Or download my cut ready poop emoji off fireshare and try that. It has plenty of curves that should present a problem if the problem is in your machine setup and not post.

Everyone needs one of those!! ![]()

The file In the video was inspected and reworked by @TinWhisperer he posted the file above. I posted the original file above his post. Cameron from Langmuir had sent me a “perfect” cut file to run two days ago and it had all the same issues. I can plug the poop file in and see how she purs. I do agree in the video it seems like it’s bouncing off of nodes but, it seems to pause for a millisecond. The file Cameron sent clearly seemed to be bouncing off of nodes. It was a ford sign. Shouldn’t be surprised that it won’t run right hahaha!

That video looks like a cut file program problem but if Tin worked it and the file Cameron sent won’t work I’m starting to wonder about stepper drivers. It looks from the video like the machine is being told to make all of those moves so if it’s not in the file it seems to me it has to be in the control box. I would ask Langmuir about switching out stepper drivers to start with and potentially the control board. The machine does not look or sound like it’s binding to me.

EDIT after I replied I took a closer look at the photo above, if the lines in firecontrol are zoomed in and on the same area the cut displayed it does look like the cut file is getting what it’s asking for. In other words those jaggies look like they’re in the cut file to me.

It always seems that when smoothing is applied the file becomes jagged in the fire control interface. Am I incorrect? The heavier the smoothing, the wonkier it appears in fire control?

I use sheetcam mostly for CAM so I’m not sure. I could run this through sheetcam for you if you want? Not sure it will change anything but it would rule out the CAM as the problem (maybe).

I would appreciate any help. I’m almost positive it’s software related. Or I’m a dingbat.

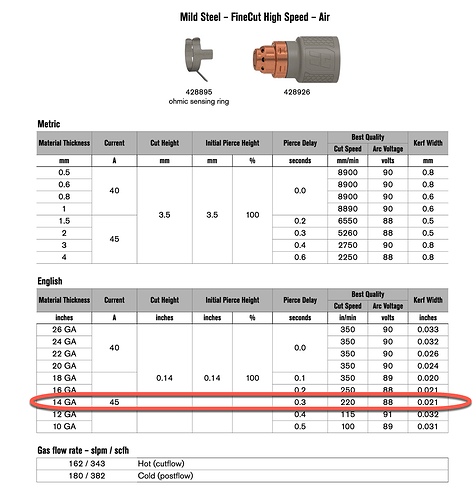

Here’s the file done in sheetcam, I did not inspect it like crazy I just set up the hypertherm settings for the tool seen here

and set up two different layers, outside which contains only the cut on the very outside ring and then everything else. I hope this helps in the troubleshooting.

F2G cut file sheetcam.tap (97.5 KB)

Scott

WOW, 140 thousand cut height that is a lot. I can’t even believe it will work at that height.