I am designing in Inkscape to fusion, I am learning software and I have been noticing chunky curves in my lettering. The long sweeping curves that were circles in Inkscape cut smooth but the lettering and intricate parts look terrible. I think it probably has to do with the design/lettering in Inkscape or a programming error. I ran through a ton of settings iPm and heat, new consumables. Can the xr cut parts this size and fine? The letter is about 1-1/4” tall. Cheers!Preformatted text

Bad nozzle or incorrect consumable set.

but looks like you have that covered.

Amperage incorrect for the nozzle or operation.?

Incorrect cut high.

IS smoothing on in your 2D profile menu?

Can you Export and post your F3D? (or share a link to your design through the data panel in fusion)

What is your air Quality and Volume like? Water issues, Pressure issues?

latest, maybe an internal torch issue.

Those are the flaws I’d check in that order.

I’m going to work up a couple test files with lettering and check the parameters. I know the file I was cutting was a bit of a Mess due to inexperience. It was my first really cool file. My desiccant was pink, I am running a good filtration system but I’m sure moisture is at least a slight factor. Im still a bit confused why some curves are perfect and some are so awful. Thanks for the info.

Some of the fonts that you get online are crap…

Uploading the f3d file will really help.

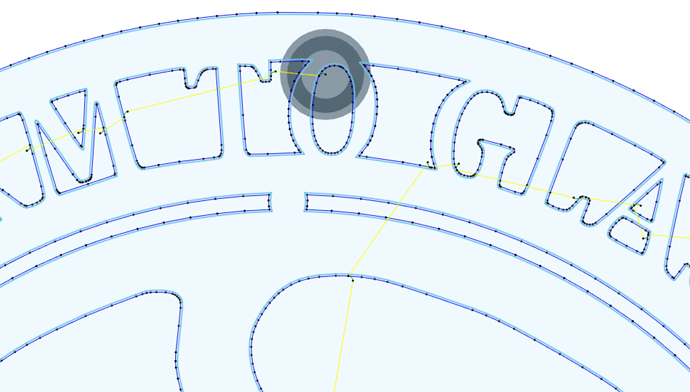

How many nodes are in that “O” in the file? Post the .svg from Inkscape

Was this a bitmep trace or did you use a font for the letters? Most traces require significant clean up to get a smooth cut.

i tried to post the file. having trouble getting it on here. here are some screenshots. the vector is slightly jagged on the edges. i ran into some trouble trying to get the vector right . i was trying to get the circle radius cutout under the lettering to become negative space and i accidentally worked some voodoo and it got jagged.

Trouble finding the file in fusion or trouble uploading to the forum?

Nevermind I see your not doing cad in fusion

trouble uploading to the forum.

If the forum won accept your file typ just change the file ext and that should work. Just let people know what you did so they can change it back.

Looks to me like the notches in your file correspond to the nodes in the post processing. Normally, they should not be this pronounced.

I do all my design in svg and post process in sheetcam from the same svg. I once post processed a font file without checking the amount of nodes, and heard a difference in how the machine ran during the cut I had to stop it and redo everything. Each node, means a pause in the machine however slight, which means a detectable notch in the cut.

The notch is usually very slight, but an experienced eye will catch it.

With your file, I’m guessing your cut speed is already too slow. Post all your settings, equipment, and material.

I agree. The notches are spot on with the nodes. I will post the svg when I have time later today hopefully. I had been under the impression that more nodes was better. The alt-b function in Inkscape will only work about 50% of the time for some reason. I had to do some unexplainable workaround to get this thing into one unified file. It left the image vectored but slightly jagged up close. I think it ended up placing a ton of nodes in the lettering and I noticed weird chunky cuts on some of the larger sweeping lines. You could here the matching bouncing off the nodes. Do you ever run into Inkscape glitches? Sometimes Inkscape will repeatedly crash and functions won’t work. It’s quite frustrating. I am using a brand new powerful Lenovo. Dedicated to fusion and Inkscape.

Check out the 24 minute Mark of this video it describes an easy way to share your Fusion file information.

Also this forum topic covers exporting and posting a f3d file to The Forum.

Yes, Inkscape has a lot of features, but it’s not polished software. It can’t handle giant drawings.

If you like Inkscape and don’t want to pay a subscription for software. Use Affinity Designer. When you set it up with the grid and rulers and snapping, it’s CAD accurate and does artistic curves and shape subtraction very smooth.

But, what are your settings and machine? Overall the cut doesn’t look right.

FBc wheel fusion fusion file.f3d (1.2 MB)

i posted the file above. some of the things i have been noticing. and things i am tring to figure out.

- when i cut at higher speeds i get lower quality cuts. i had thought that higher speeds could make the cuts smoother.

- when i am cutting long radius’ sometimes the radius cuts seem to pause or (glitch and the motors on the table make crazy robot frequency noises.

3.sometimes my x axis will bind up when i first start my table when i am running at 400ipm. i am not sure if it due to the chipping paint on the gantry or something else. i meticulously squared everything yesterday. - x axis paint chipping is causeing some vibration is causing i think it is a normal amount. i placed vinly tape under the bearings and it ran much better. let me know if this is normal stuff.

- im sure i overthink alot, its just hard to figure out how to get the best cuts when first staring out. any info is greatly appreciated.

@TinWhisperer i posted the file above if you have a chance to check it out. thanks!

@brownfox

so its been a while since i did this cut, i got caught up with work and im back at it. i was running 45amps

168 ipm

100 psi

standard cut consumables.

i have since switched to the fine cut consumables. this has helped a bit with quality.

i also started cutting slower, around 50 ipm and lower pressure. i just purchased an air dryer so i should have the quality control good on my side . some of the issues are ironed out but some glitchy lettering is still persisting. i was really hoping to be able to cut designs at higher speeds. i will cut another copy of the file i am speaking of and see what improvements i have made. i will also record all settings and post.

so the affinity designer should be a better fit for me? i am looking to do some pretty large intricate cuts in the future.

thank you all for the help.

I was just reading through this and I did not see where you said what thickness your material is.

One I will say is when your trouble shooting making a large change in your settinging and changing more than one thing at a time is bad idea.

You were at 168 ipm and went to 50? thats a huge change.

Why dont you share the following:

What cutter are you using?

Material thickness?

do you have your air figured out? If so share your set up. Compressor size, what do you have in place to aid with drying your air?

Are you sure the air pressure on the gauge on the cutter is steady while cutting?

Have you gotten good cuts in the past?

If so were they artsy pieces like your trying to cut now?

Forget higher speeds for now and concentrate on good cuts, then you can chase faster.

When you first get in a race car, you don’t start out going fast till you learn everything else.

Cut chart for Powermax SYNC

looks like 270 ipm for 14ga with the standard cartridge cut height of .125

& 220 ipm for 14ga with the finecut cartridge on high speed cut height of .14

FBc wheel fusion fusion file tin forum twtich stream v1.f3d (2.6 MB)

check out this live stream but the drawing is not that too bad.

I made a few change in the work flow and a couple in the 2d profile settings .

For some reason the sound is muted…

hypertherm 65 sync w/ 30-45 fine cut pod

16 guage steel

80 gal ingersol rand dual stage compressor

harbor freight air dryer.

smc dual filter off of the compressor

motor guard toilet paper roll.

i set my pressure at my main reg/filter then it hits the smc regulator filter then air dryer, then it goes to toilet paper roll, then small stock hypertherm filter then i tee into my gauge, this guage checks for pressure differential. i always have totally smooth consistant pressure at both gauge sets. i have gotten one cut that is about 90% quality. the good cut, i made sure to upload and then ran pretty heavy smoothing and it helped.

the drop from 168 to 50 was me checking to see if mabye i had overtightened the rails and the motors couldnt keep up with the speeds.

thanks!