Holy crap… .060"?! I wonder what results someone could get from starting with a better toleranced fixture plate. I would love to machine my own and get hardcoat anodized then add some steel bushings and thread inserts… The baseplate is my biggest question mark with these machines.

Yeah, i thought the same thing. My concern with having to face that much off to start with, is that i am milling the surface plate with a z head that has not been trammed in yet, so really dont know where i stand, and next after i surface the plate, i plan on checking the traming. After that, i will have to surface it again. hopefully not much, but it is still material that has to come off.

Well, spindle break-in has been started…1hr left.

the smaller the endmill you use and the smaller the step over, the less tram matters… maybe find the highest spot, surface it then check tram on that surface with a 123 or 246 block before steping down and doing the whole plate.

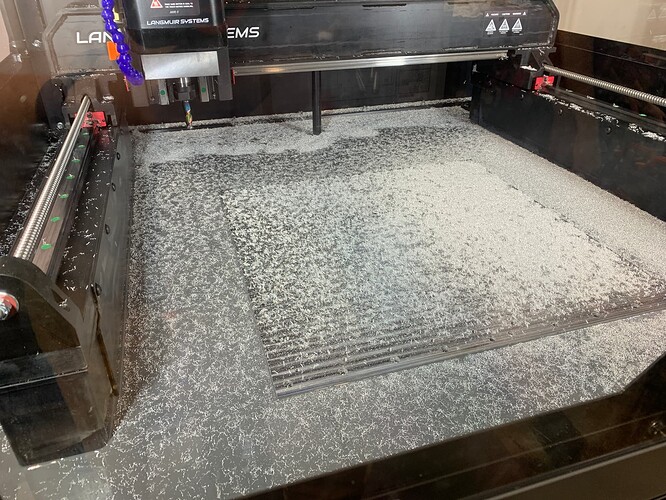

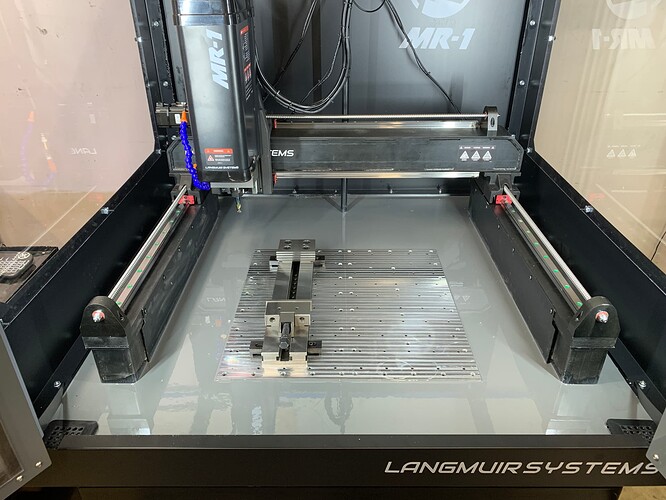

Well, spindle break-in is complete and the plate has been surfaced. Man, what a beautiful sight it is. It is the cleanest it will ever be at this point…LOL Going to look at tram tomorrow and see where I am.

Very good job my friend ![]() . I bet, milling that base plate has a very high pucker factor?

. I bet, milling that base plate has a very high pucker factor?

Go have a beer and look at it…

It was a little nerving when I hit the start button for the first time but everything went good. Can’t wait to get the first part going

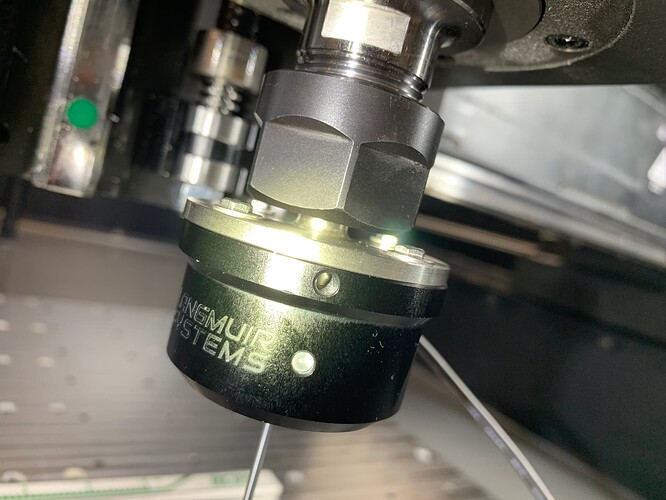

Ok, for those of you that have got your MR1 together and have done your touch probe alignment, were the adjustment screws in the touch probe or in a bag. I dont seem to have anything.

In the side of the touch probe. 4 tiny set screws. I didn’t have a allen wrench small enough in my set. I think it was .050

@Bigdaddy2166 Well, thats the thing. There are no set screws installed. @langmuir-daniel Were these in a bag somewhere or supposed to already be in the touch probe? The tool setter has them installed already.

Trip to ace is in your future. Or maybe a R/C

Store. These set screws are the smallest I’ve seen for a long time.

Yeah, i was thinking that. My lowes and home depot suck around here. They never have anything.

Just loosen the bolts on the back center the thing up and tighten them back up. This way you can use it till langmuir sends you some. They do almost nothing in changing the probe.

Maybe…002 maybe.

It will get you going for now. Unless you have a part for NASA planned ![]()

I have a bad probe. I could overnight you the set screws if you like. It would still be Wednesday before you would get them.

By the way you need one of these. It’s awesome. Works 10x better than the original. Acetal Copolymer, Flare Nozzle, 1" Width, 1/4

Loc-Line Coolant Hose Component, Acetal Copolymer, Flare Nozzle, 1" Width, 1/4" Hose ID (Pack of 2),41407 https://a.co/d/h3tf2Ch

Mine were missing the screws as well. Langmuir sent me replacements. If you’re impatient, they’re 6-32*1/4"

Hey Thanks @ckoval7

Damn, spending my money again are you… ![]()

Yep. I know you’ll want one. Don’t forget to put a 1/4 street L on the coolant line like MrmachineTX recommended. These will keep you from opening the doors 10 times per project.

You want me to send you those set screws?

Be Tuesday morning before I can ship them.

No sir. I will try to find them locally. But i appreciate the offer.

In the shopping cart…LOL

Sorry pal, you’ll thank me later. ![]()