Someone did a lot of printing of a benchy to create that animation or is a rendering?

Okay, I went back to work and turned it back on. I can now do work at home. Thanks for the help, you guys.

Once!!! ![]()

Then you will have to run back down there to take your print out and clean the plate. I can see it now: BigDaddy is going to buy another printer so he can remotely change his mind! ![]()

The second one is getting delivered tomorrow.

UPS has a return to sender request. The still shipped it from Rancho Cucamonga CA to Chattanooga.

Maybe I will just keep it ![]()

It’s only money.

What is money to a good looking guy like you?!

…But, you will need another cart.

BD, with that photo in mind, most filaments are hydroscopic (will suck moisture out of the humid atmosphere). Don’t store filament spools long term in open air, if your intent is to store / use the printer out in your shop. You’ll know that the filament is getting saturated when you hear “pops” as the filament is being extruded. You’ll also see little “nibs” off the sides of the extruded filament and your part.

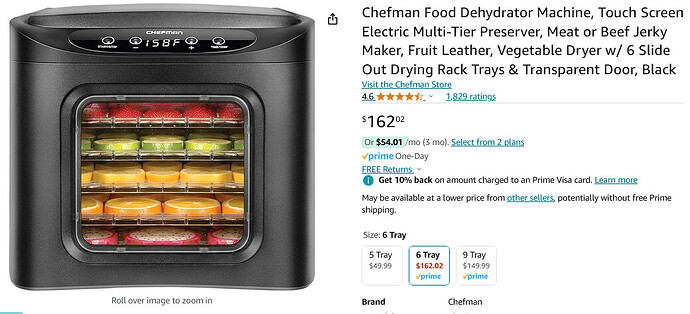

Get a filament dryer (or there are dehydrators on the 'zon that works well for this purpose… Amazon.com , and dang that thing shot up in price, was $100 a few months ago) for when you find that they are saturated and need to be restored.

HIGHLY recommend a sealed storage tub (Husky red ones from HD work well) with a liberal amount of desiccant inside to keep that lake’s influence at bay.

I noticed the same thing!

Edit: You can get the 9 tray dehydrator cheaper than the 6 tray version. Must be supply and demand.

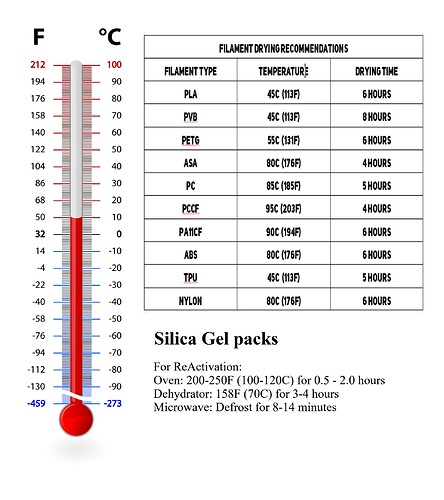

How exactly does this work? Won’t the heat melt the filament? I bought a creativity drier off Amazon. Is this thing better?

The dehydrators are not going to get hot enough to melt the FDM material. Your melt temps are north of 190c (374f) You are drying it, not cooking it. Even the kitchen oven set at 150 and leave them in there for a few hours is good.

It maybe the expensive way to go but a AMS is more or less sealed so then you can storage and have access to up to 16 filaments at the machine.

The X1 Carbon itself can also be used as dryer . There are setting on the machine so you may load filament roll onto the bed on the machine and it will run through a drying cycle.

Myself I am going to use a pressure cooker and one of my refrigeration vacuum pumps to degas the “wet” filament. I have one roll of PLA-CF which is unusable currently that I should try this method on .

In agreement with everything that Tin and Sticks said.

I use the dehydrator when I am doing lots of drying. It will hold 5 rolls of filament and you can set the timer for longer times (like 12 hours). But you can damage some filament if it is dried for too long and at too high of a temp.

Both the Chefman dehydrator and your Creality Filament dryer have a top temp of 70 C (158 F).

The filament dryer is great (indispensable) when you are using a filament outside of the AMS, such as TPU. TPU is really susceptible to moisture and will not feed thru the AMS.

I am finding lots of other uses for the dehydrator:

- Dried my wood pellets that set out over the winter and absorbed enough moisture that the Traegger grill could not get hotter than 325 F even when set at 450 F. Once the pellets were dry, I got to 427 F even in 40 F temps outside.

- I dry my Wet n Wet desiccant packs, 20 or 30 at a time all laid out on the racks.

- Recently dried a bunch of small metal parts I cut with my Langmuir table, soaked in vinegar for 24 hours, rinsed off and right into the dehydrator to limit the flash rusting. They still rusted a bit.

But as others have mentioned, there are lots of options for these extra drying tasks. You did right by buying the Creality filament dryer. It will come in handy.

I just keep mine in the cardboard boxes they come in, but I also live where the humidity is almost always 20-30% so my whole house is a dry box.

So Jimmy, do I need to order this toaster oven?

Not yet. Wait till you see you need it or the price comes back down. This waterproof Husky bins that Andy mentioned, are a real good idea. I have two of them.

Like Tin said, there are other options for drying: oven, the printer and you have your actual filament dryer. You will know if you need it in a few months. I really don’t use mine that much for filament.

Is your area pretty humid? Ours IS as we live on the “Wet” side of Washington state.

IFF you trust your kitchen oven to hold within a certain tolerance (I wouldn’t).

Pressure cooker + vacuum is a good idea, although they have chambers for vacuuming things inside of.

Come to think of it, I haven’t checked if mine (vacuum pot) would fit any filament rolls for degassing…

Come to find out, they FIT! WOOT

This can’t be that complicated. I will buy the toaster oven and see how that works.

I have, at this moment, ABS-CF, PETG-CF, PLA Basic,

and some ASA filament in multiple flavors.

I need good UV and hard plastic. Which is best and least susceptible to dew point?

Now I have green pla and it works great. My white PLA leave small tits that are like 1/64 high and every thing goes to shit after that. Only the white. It must be wet. I have 3 extra dessicant bags in the AMS including the two from Bambu.