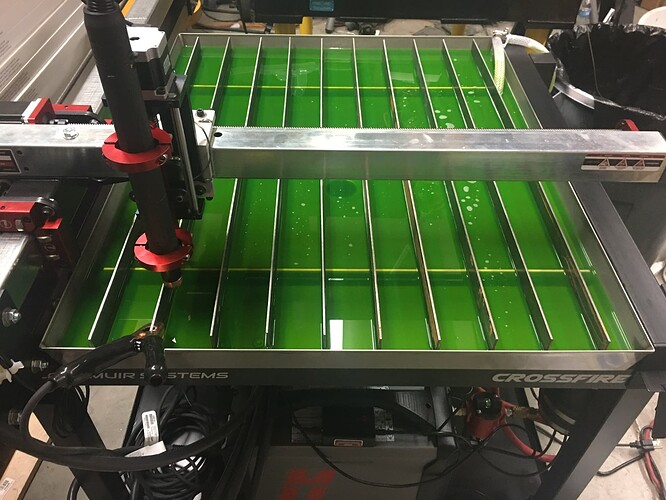

Like a charm (after a little die tlc ![]() ). @72Pony will have these headed your way shortly.

). @72Pony will have these headed your way shortly.

Outstanding! Nice setup

Wow that looks awesome!!

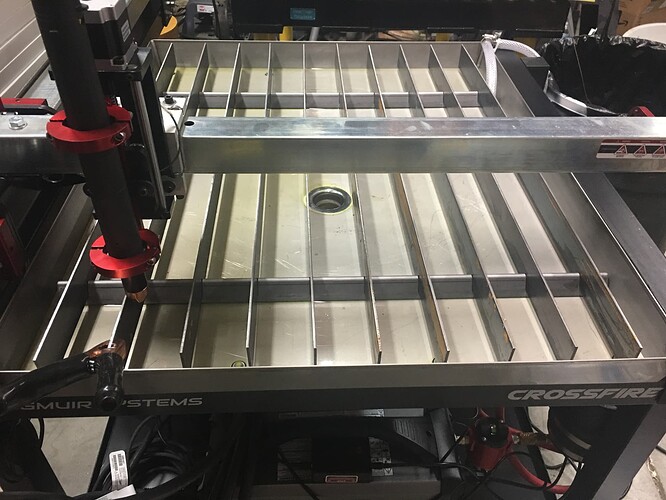

I’m excited to have larger, faster drains! I’d like to do the tank route eventually. Need to make a base and shelf first.

I plan on doing this on my new XR table. I picked up what I thought was the bar drains in the Menards link in this post but instead I picked up a different version of bar drain which has a deeper strainer. It happens to be Chrome and not stainless steel. I have not installed them yet but wanted to see if I might be able to get some input on using Chrome instead of stainless which is more durable. I am thinking I might be wise to return them and get the stainless ones. I plan on using Sterlingcool for now but you never know what else might come down.

I’m 99% sure you would be fine. My thought process was since the pan was stainless I’d run stainless drains to minimize any chance of some strange galvanic action happening. Given their application (just a drain in a dirty water pan) I don’t think there’s real durability advantage either way.

I appreciate you chiming in as this is not my area of expertise. The chrome ones were actually more expensive, but I really like the deeper strainer which I had planned to fille with scotchpad. I might just go ahead with them tomorrow. Got the water pans installed and caulked today.

Lots of chromium in stainless, so shouldn’t be an issue either route. I’m pretty sure mine is the chrome version. We can compare notes of who’s fails first. ![]()

my table drain set up is almost the same as yours…but instead of 2 filters I used a single cartridge water filter…rainbird…

your set up is nioce and clean…wait a few months…ahahahaha

The dies worked great! Thanks for doing this!

I’ll take some pics and post them here when I finish my setup.

Dies are on their way to @mnicolia ![]()

How can I get on the list please?

reach out to @mnicolia

Once I receive them @jazzato and use them, hopefully by this weekend, I can pass them on to you.

I’d like to get on the waiting list for these dies as well…

Special Thanks to @nortonscustoms not only for sharing his information but also sharing the dies with the entire group. This is the way I’d always dreamed the internet should work… a big virtual group of enthusiats hanging out in a workshop together and helping each other to get things accomplished. Bravo!

-TM

Dimple die worked great! Don’t know how anyone else was cutting the holes, but I just used a hole saw, and drilled through the old drain and plug…worked great didn’t even damage the old drains so if I need too can use them for another project. Also anyone wanting to know what drains other than the Mendards ones, I used Amazon Bar Drains. They worked perfect. I reached out to @jazzato because he is next on the list.

@nortonscustoms Do you have the specs or F360 file on these dies? I would like to turn a set myself.

Looks good! Thanks for the link to those stainless drains too. I bought the Menards ones already, but those Amazon ones are cheap enough that I’d switch later if I felt like it.

Timing seems to be good here too… @jazzato is up next, and that should give me just enough time to get a few things unpacked!!!

-TM

JDE

I don’t have any drawings for the dies. I just measured the pan thickness and the drains. Scratched a couple notes on a box lid. But if (and that’s a sizeable if ![]() ) memory serves me, think the step was like 2x the drain flange thickness and the clearance between form edges was 3x the pan thickness. 1-7/8" pilot.

) memory serves me, think the step was like 2x the drain flange thickness and the clearance between form edges was 3x the pan thickness. 1-7/8" pilot.

I would test/practice on a piece of scrap the same thickness as the pans. Key is not to form the step too aggressive and risk shearing the pan or over stressing it and get an oilcan affect. Too loose and you’re fighting spring back more and a less clean fit. Hope that helps some.

These are the ones I used on the advice of @3535

Not cheap but they are nice and deep.

I used a hole saw also but I just drilled through a 1x6 and clamped it to the water pan with some welding clamps

Address sent… Thanks

JDE, I was going to give you measurements from the dies, but my calipers have come up missing, they are usually next to my lathe, but sometimes my father uses them. If I find them before I ship the dies out, I will take measurements and send you.