There was an ATC thread started about 8 months ago.

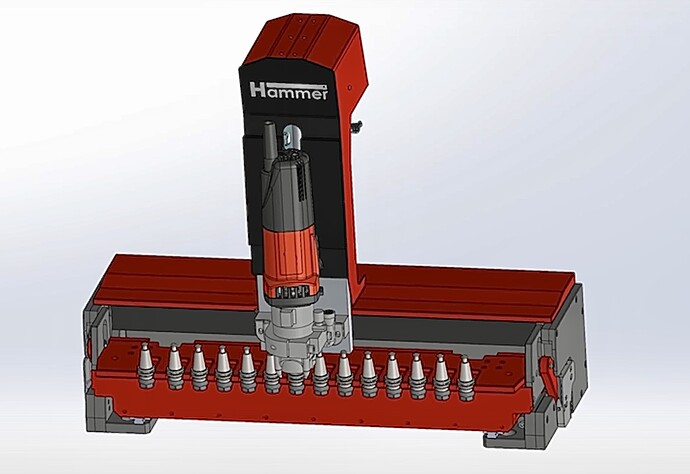

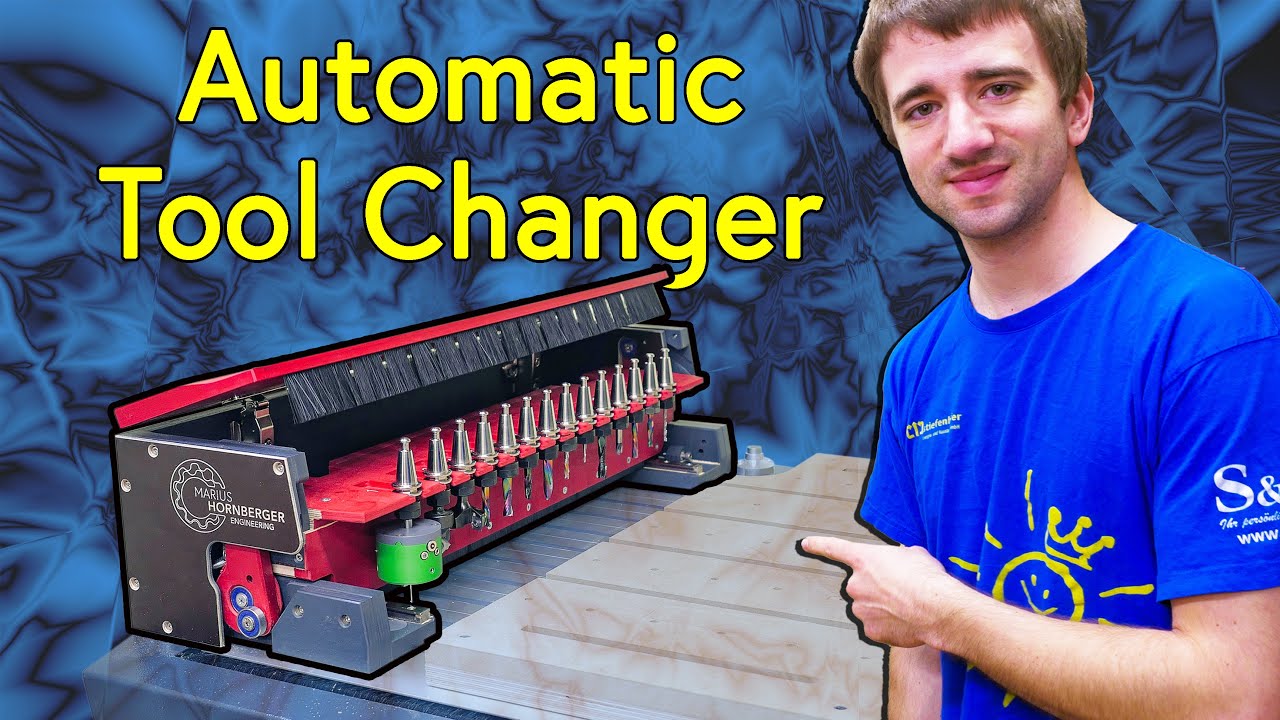

Is this what was meant by a wine rack style changer?

My issue with a low profile or table height changer is that it would often emerge through a big pile of metal chips. So there would need to be a method to make sure the tool holder was chip free before inserting it into the spindle.