I get it, and I’m ok with it, however the trouble with the lack of an ATC is not so much the time you would gain during tool changes. It’s the time you would save by not having to babysit the machine because of the manual tool changes. Not a problem for the intended use of this machine, but a headache if one would like to use it for slightly more ambitious production runs. Standing in front of a machine waiting for tool change time is no fun, and definitely unproductive. Having said that, I’ll learn to live with it for the price.

I think something like this can be a good option for a toolchanger. Probably servo activated to save space.

Datron also does something like this.

The ER20 collet system will not allow this type of changer. Not sure if it could ever be done without extreme modifications to spindle. Just my two cents.

Yes, would require heavy modification.

Basically would install something like this

Put the pulley on it, plumb it up.

But hard to say what’s possible without seeing inside what’s already there.

Also it seems like the assembly I linked is only good for 3000rpm?

Interesting. Keep us posted

The RapidChange system (in that video) is a non-trivial add to the MR-1. It is probably more work than swapping the spindle, but perhaps cheaper.

It requires reverse (which the MR-1’s default control doesn’t support) and it requires that the spindle can be stalled (the MR-1 servo drive will fault when stalled).

That’s why I have a problem with it. Those who claim something is “affordable” should at least respond when asked for the price…even if it’s not finalized. The kickstart link for the Samurai 120 has been disabled but I remember the price for their 14 holder ATC was quoted at £1500 or approx $1900 US. Now that the milling machines have become available the new price has gone to $3800 and they don’t sell the ATC separately.

What would you consider affordable for a hobby mill? My thought would be under $1K for an ATC ready spindle and under $2500 for the ATC not including any electronics.

Here you go…

https://rapidchangeatc.com/product-category/magazines/

$825 for all of the options, for the ER20, and their documentation states explicitly that it does not support the MR-1

I had gotten a full quote from samurai a while back and everything to make the machine similar to the MR1 but with a power draw bar (no ATC) I was quoted around $13.5K after shipping.

It’s not too far off a fully assembled MR1…but for a similar price we got the assembled MR1 and a whole buttload of tools. Plus the lead time for the Samurai I was told, would have been next year.

Not sure how reputable they are either so we went with the Langmuir machine.

The cheapest ATC ready spindles start around there, but anything worthy of being on the MR-1 (with specs close to stock spindle) will be about 3x that price. Tormach’s power drawbar is $1500, without including any spindle parts.

I’m doing the conversion this fall using a CNCDepot spindle and will post my progress. I’m currently drawing my spindle adapter plate to figure out which spindle design I want to order.

Yes please post. That will be great.

It’s odd to me that they call them power drawbars since they are simply a spring loaded rod designed to provide tension for the pull stud. The power is actually applied to compress the springs for “withdrawal” of the tool holder.

I don’t know how Tormach justifies $1500 since the only sophisticated part is the pull claw. The rest is a threaded rod, nuts, spacers, o-rings, and some disc springs.

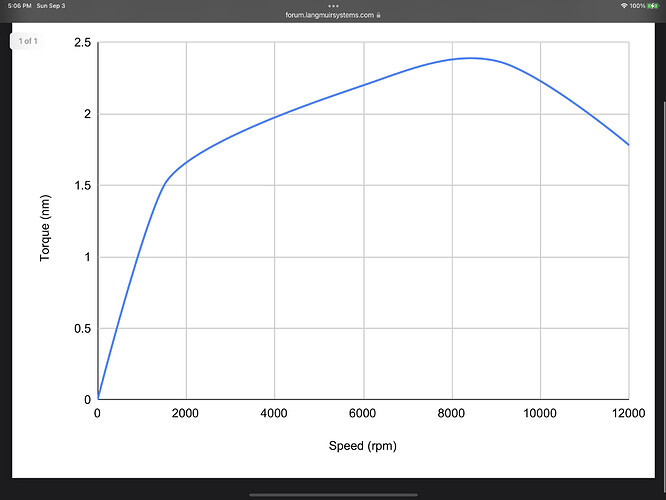

On the CNCDepot spindle are you considering the 4 pole or 2?

4 pole. There is going to be a torque drop compared to the stock spindle, and with the 2 pole I think it will be too much. The primary high torque / low rpm operation that I’m worried about is drilling in stainless steel.

The 4 pole motor can be run in a range of 500-16000 RPM with a high frequency VFD (530hz). That feels like it is getting into the right range for this machine.

Your other post has me thinking about this again because I’m now worried about tool holder length – I’m glad you brought that up. Spinogy makes nice looking spindles for SK20 (ISO20?) and HSK25, but they are significantly more expensive than the CNCDepot one. A 4 pole SK20 spindle is 4320 euros without any tool holders or VFD. CNCDepot’s spindle is $3000 bare or $4000 with the VFD and 8 tool holders.

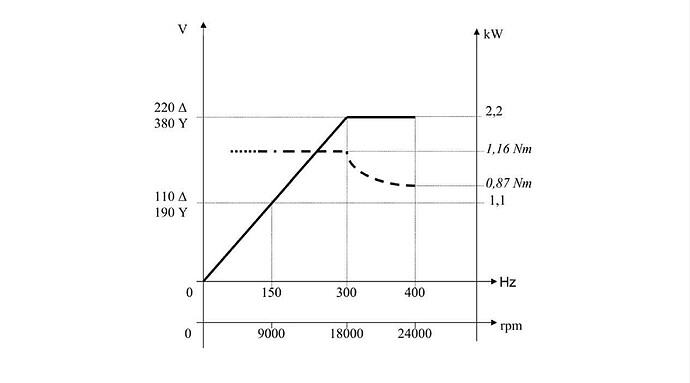

That was why I asked. There were links provided but I tend to forget specifics when I don’t see the graph in the thread.

This was the CNCDepot 2 pole graph.

And this was the 4 pole. Hard to know how it performs above 12K.

The 4 pole looked better without sacrificing so much low rpm torque but I wondered how it would compare to the MR-1 if it were feasible to step the differential ratio up by 3 or even 4-1.

Yeah, I thought the carriage height was kinda the elephant in the room. The rack style tool holders we have been seeing are ISO20s and when holding one and a ISO30 holder in person you really notice the size difference.