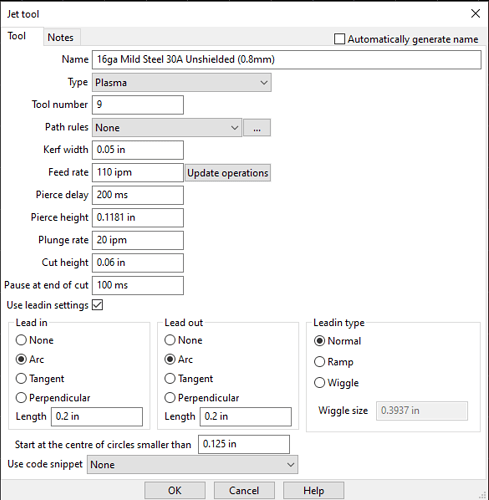

I have some 16 gauge galvanneal steel and 14g galvanized that I am having major dross issues with. No matter what settings I adjust I cannot get the dross to go away. I’ve used new consumables in adjusted air pressure, amperage and speed, I haven’t come up with a good solution. I bought a mag chuck but I’m hoping I don’t have to use that every time.

What kind of plasma machine are you using?

If you cut 16 or 14 gauge mild steel you have no dross? and when you use the same settings on galvanized you have major dross?

Have you tried to grind away an area for your work clamp to be secured to on your material?

I cut quite a bit of 26 gauge galvanized using the mild steel settings straight from the hypertherm book.

And I get almost zero dross on it just wipe it down and straight into the brake.

Using a prime weld cut60. I’ve cut cold rolled and have had better success. I’m clamping to the water table with machine ground and a grounding rod.

Put your work clamp on the material being cut and try again.

Use whatever settings you have most dialed in for that thickness in mild steel to start.

it is called a material clamp for a reason…it clamps to the material…

clamping to the water table can result in arcing between the slats and metal and surges in the THC readings…I have even seen thin metal get burns from the arcing.

My go to material here in the shop is 16g Galv Steel sheet. Minimal dross, using my CUT60. Dross is easily removed by a 2" paint scraper. My settings are as follows:

BE careful with the fumes emitted while cutting galvanized, IT’S TOXIC.

Do you cut the 26 gauge over water, doesn’t it make the galvanizing look bad? I was thinking of having a transition with fan setup underneath it that I could slide the water pan in when cutting thicker metal.

Welcome to the forums Bill.

Yes I do and no I don t think so .

I wipe the water off the parts and start bending them up; the finish is not really effected.

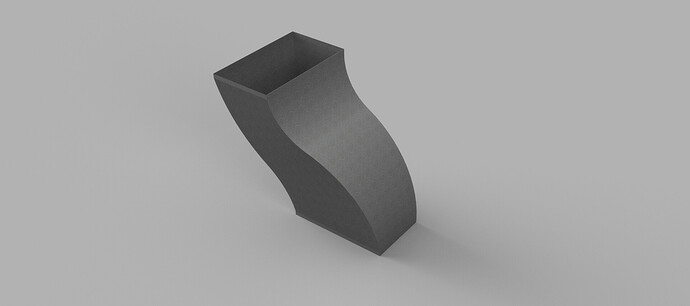

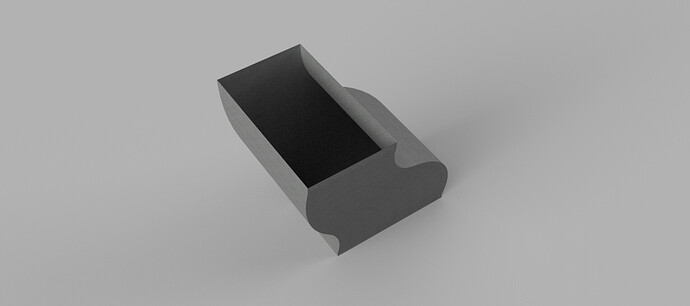

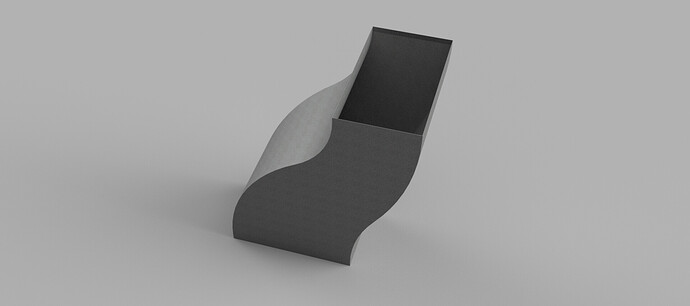

Check this topic out where I build some square to rounds from 26 ga galvanized .

there is a video link towards the bottom of that topic link of me cutting26 ga galvanized on the Langmuir Pro.

The only thing I’ve changed since I made that post is I run it at 25 amps instead of 40 amps.

Thanks much for replying. I’ve been doing it by hand for a long time and just picked up a cnc, not together yet. I’m hoping to save time and my hands.

Oh oh. You’re gonna give @TinWhisperer heart palpitations showing him pictures like that!

PS: Welcome to the forum…

Looking good. looking old school, which is my favorite.

Are you installing Rheem?

Maybe a RCH series coil. RCF3617 or RCF2417 has the same cabinet?

I see your a single cross brake guy.

I hear you. I have been budgeting to buy an XR so it will fit a whole sheet. The pro is a little small for a lot of fittings but but smaller square to round, offsets, and tee s it can be pretty sweet. I still mostly hand layout and cut while I develop more programs and look forward to getting a bigger platform.

Here is a recent fitting that was too big for the machine and I found quite challenging to layout out and produce a nest in fusion 360.

I did end up figuring out workflow in fusion 360, it came too late and the dividers won the day.

Check out this linkable 3d viewing file from Fusion 360.

Very nice to have another HVAC guy on the forum.

Nice work, lots of messing around making some of those fittings. I taught myself hence the single breaking. Haven’t used a cad program yet, been doing the old way.

The shop that I apprenticed at had three journeymen that all cross broke in different ways.

And if I was building a fitting for them I had to make sure that I was using their style cuz they’re all super stubborn .

Single cross brake

Double cross brake

Single fold back brake

Do you have any good old pattern development books? I have a small collection myself.

I am slowly learning more and more CAD techniques and workflows they are invaluable.

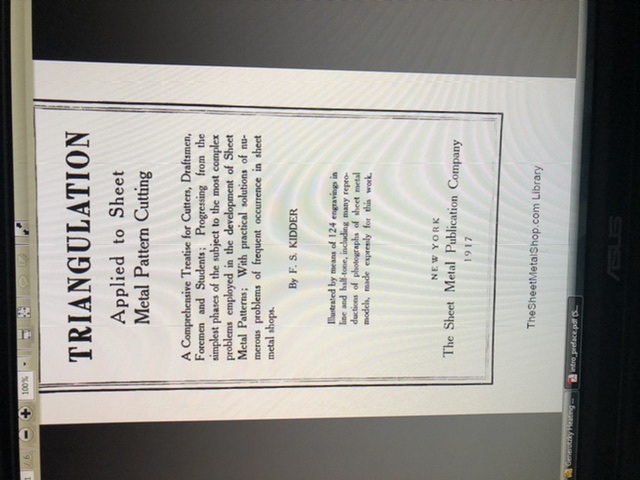

That’s funny everyone does it differently I mostly do it the old way. Yes I have some very old stuff I found online early 1900s maybe even late 1800s and a few some from the 70s and others from 2000s. I’m using some tools over 100 years old.

I’ll have to look that one up.

is that furnace a Rheem?

Yes it’s a Rheem. I just tried to look up the site I got it on and couldn’t find it. I’ll list it when I find it, if they’re gone I’ll send you it.

great…duct and furnace porn…!!!