I have made quite a few square to rounds over the years but this is the first using a CNC.

Over the years I became very familiar with laying out and fabricating square to rounds by hand.

When SketchUp came came out I started laying out fittings in that CAD environment , Acquiring all the true lengths, then stepping out the points with a compass on my sheet metal.

Then I bought a bigger printer and could print out sometime 20 pieces of paper glue them down to the sheet metal, then cut out of the fitting.

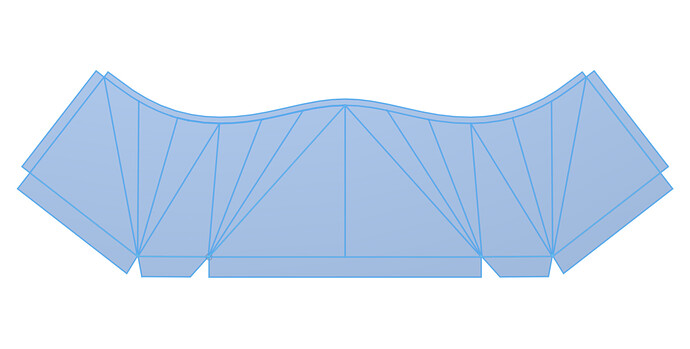

I have been trying to move as much as my work flow over to fusion 360 . I had to learn how to properly model and flat pattern a square to round in f360 environment.

Here is some of the process

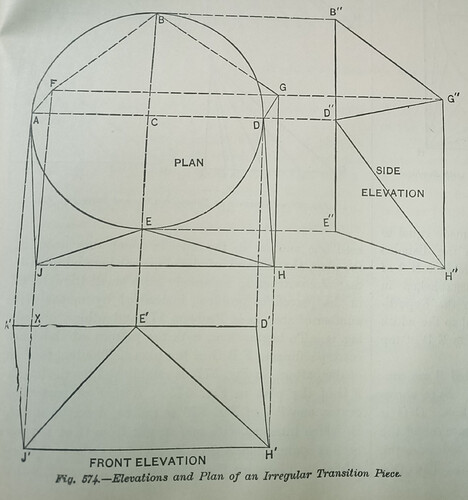

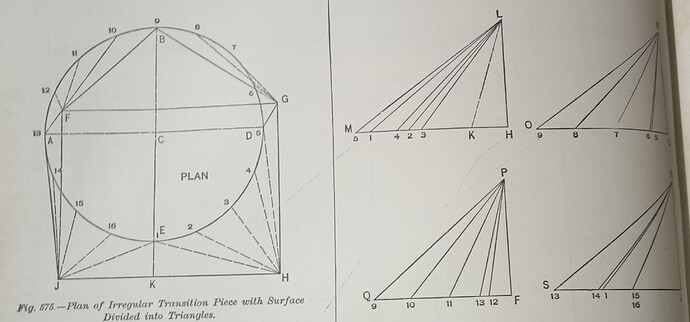

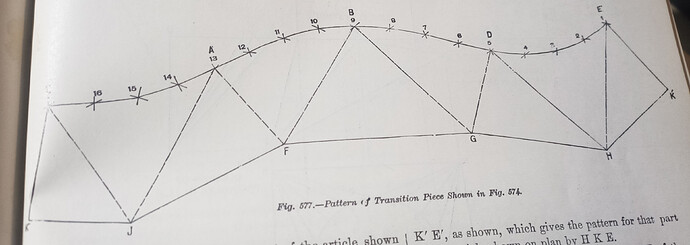

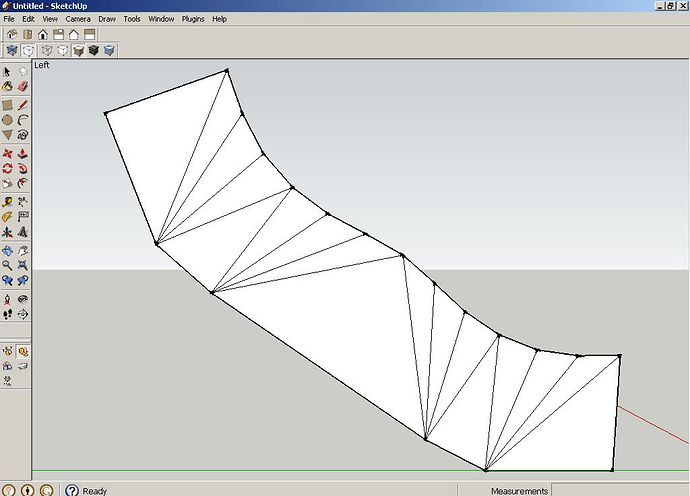

This is a typical flow by hand to produce a irregular type square to round.

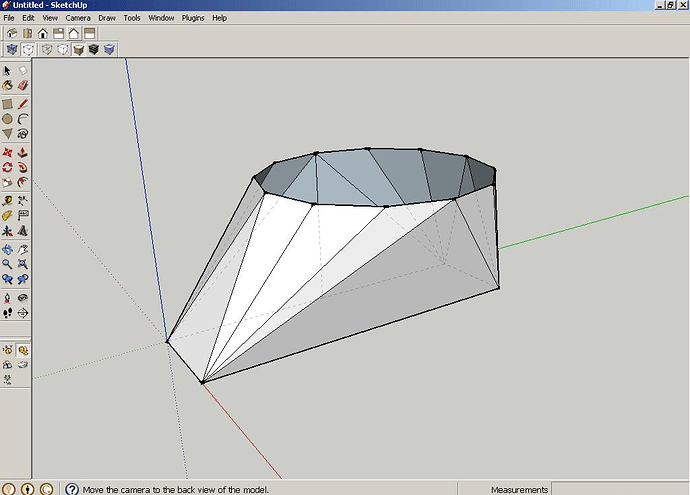

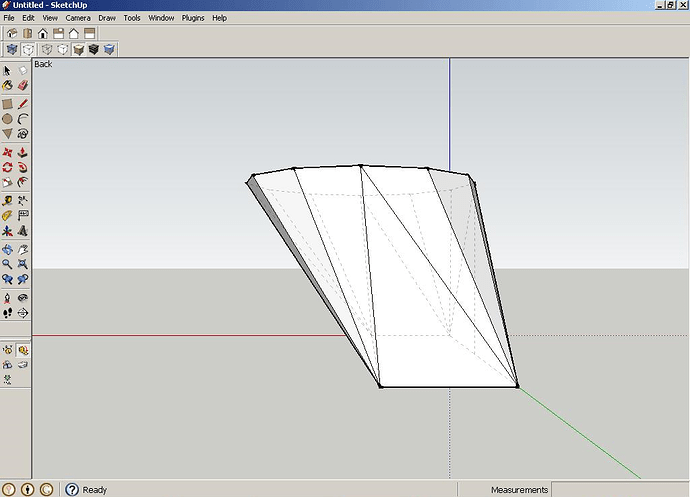

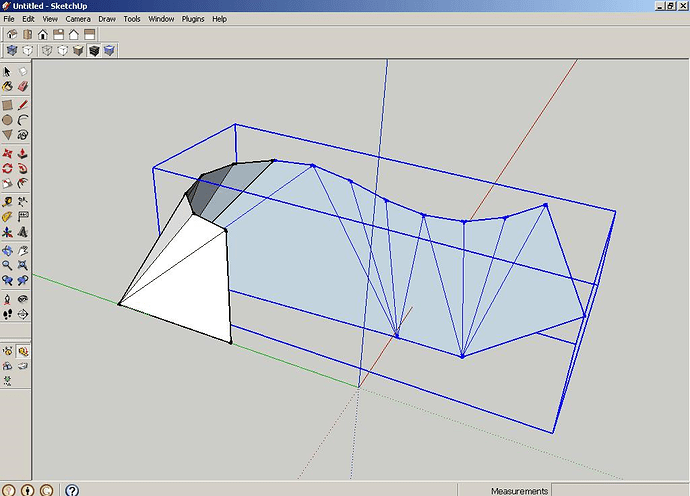

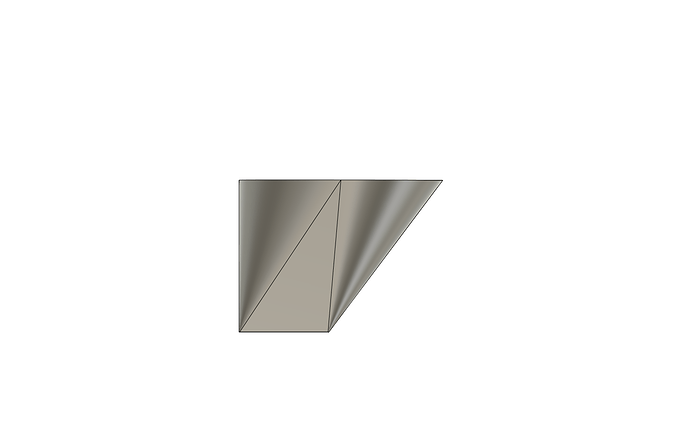

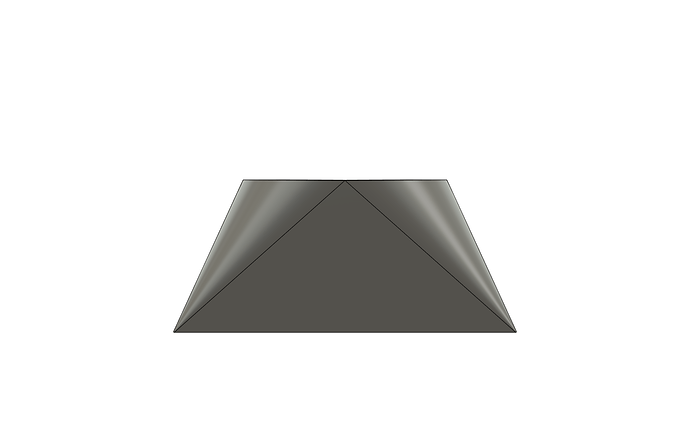

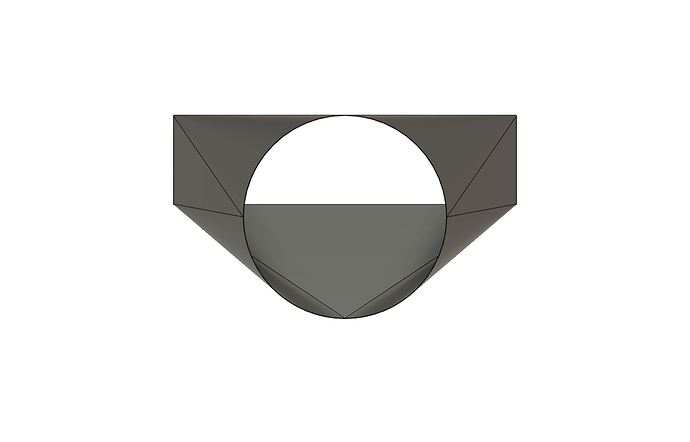

Here it a few shots from the sketchup8 method

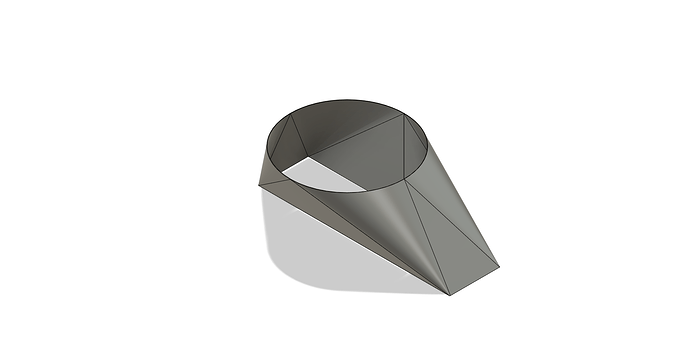

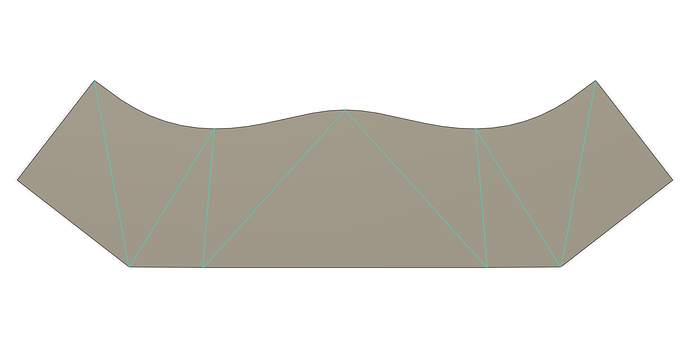

Now Fusion 360

Add allowances

Zero clean up off the table besides wiping off the water.

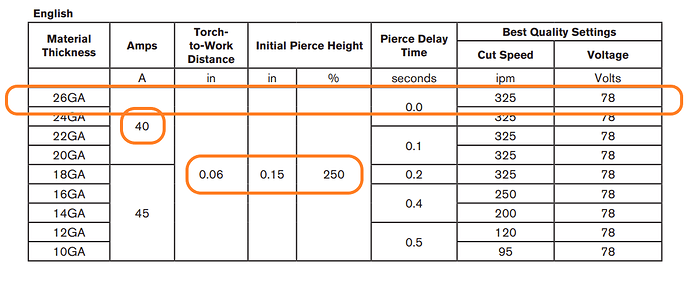

(.021)26ga galv 40amp 300ipm kerf .018

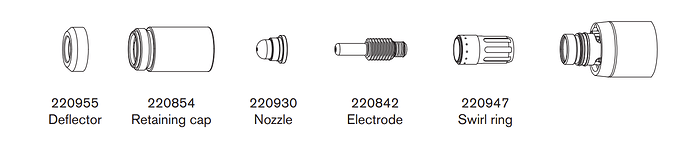

I am running a powermax 85 with finecut consumables I am as close to book as a can go

one inch notch for the slip and drives.

that hole is .06 in diameter

I am going to find my other set of rollers and do a different seam on the collar for the next one.

It fit very well for the first HVAC fitting off my Langmuir.

I am going to grind away at this workflow till I get to polished.