Yeah can’t wait to get it hooked up, air lines ran etc. Much needed shop cleaning. Im always on the scramble so nothing gets put where it needs and or too many things get neglected. My shop floods in the summer so that never helps with time and or where I can put certain equipment. I did manage to paint it right bf snow came so that was a few years overdue! Been working on some electrical stuff too. Need to run some new lines for compressor and welders etc.

Yeah, that looks like a nice compressor.

Yeah they are top of the line, very expensive. I think this unit is like 5500 or more. They are pretty complex inside. Iv already had to have help working on it. Low hours though, should last a good bit. Its pretty quiet compared to normal compressors.

Just ordered a couple of these. Made in USA. My X axis coupling has just been a headache. Iv stripped one head out and had to weld a nut on it to get it off, got new set screw and then the coupling was too not snugging down evenly. I thought the leadscrew may have been turned down too much. So I went to take it all apart and check it, then the motor side was so tight I couldn’t get that set screw out without busting something. So welded a nut on that to get it off. Needless to say yesterday was a big fight. So I had to build my own coupling. Oh and I think the stripped the alluminum coupling provided too, so it just had to go. On the Y axis those have been ok, the X axis has really came off track way too much, so this is long overdue.

Ruland CLX-4-4-SS Rigid Motor Shaft Coupling, 1/4" x 1/4"

started on the deeper table too. waiting on drains to come. This is about 1.5" taller and wont leak!

@directioneast how are the riser plates working? I am drawing a set up today and I actually need to shift my Y axis back toward the back of the table with an offset in the plates because of my torch mount. Also I second what was mentioned above with the silicone funnel. I had a chronic THC issue caused by splashing on the Z lead screw and lead nut, the funnel has helped tremendously.

The taller stanchion plates are working great. It has really helped keep the z axis clean and the rails. Still get some splash up on the rails but not as bad. It was nice to load some longer sheets that I wasn’t able to bf. I raised rails up 3". Should have water table done this week I hope.

I added a .75" offset in my test stanchion plates to move the torch back from the front edge some. What thickness of material did you use for your plates? I have some left over 10ga, I wonder if that would be stiff enough.

thats a good idea. I used 3/16 . I been thinking if I had more time, I’d build a new track system that isn’t as wide as LM. you could easily gain 2 or more inches of cut if the Rail system was different. Also I thought by putting the X axis lead screw on top of the X tube instead of behind that would keep more debris off it and get you a little more room too.

Where did you order these from please sir. Stainless? Im assuming with the SS in the part number they are.

If that is in regards to the coupling, check on ebay lots on there.

I found one on Amazon for 9.00 but they only had one. The others I found on eBay, one for 19.55 and one for 23.00. EBay was the same seller but since I put a ‘watch’ on them I got an offer to buy one for 19.55 but could find no way to buy two at the offer price so the second one was at listed price.

So if you guys haven’t heard the 20.6 update is out. I was able to test it bf its launch and its def the best version so far. Couldn’t have come at a better time bc I made the decision to get another PRO table ordered. That way I’ll be running two cut stations and have someone helping me when that time comes. I just can’t see using the xfire at this time simply bc of the quality of cuts and time savings compared to the PRO. I do plan to convert my two xfire tables to a pro in the future when LM offers up an independent add on Z axis.

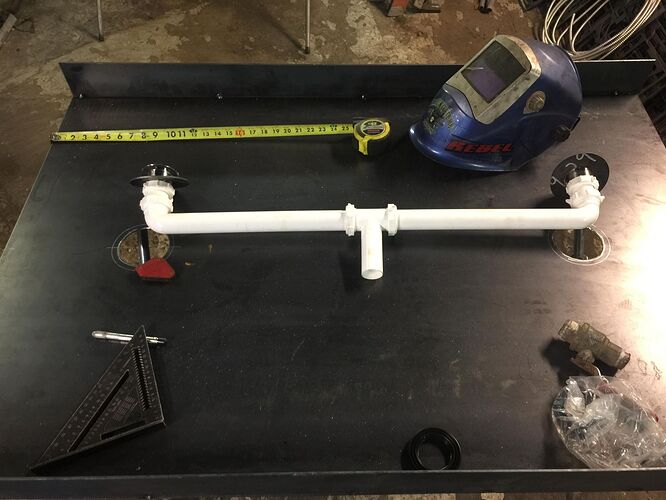

Time has been insanely scarce as Im building a 50" press brake and doing some work around shop, filling tons of orders and need to get this water table done. I managed to get some plumbing for it, just need to get some hose to connect to my ball valve, weld it all up and install. Got he drains off ebay, didn’t realize they were plastic so might upgrade later. They are 1.5". I made a recess in the table rather than dimple dying the centers. You’ll see better once I weld it up.

This will be one of the FIRST mods I make to the PRO table!!

The stanchion plates IMO are a must, so much better with it raised. Iv yet to hook up my water table. I have another pro coming and was just goin to wait and put it on that, but should def help. I’ll use it for the 65amp I run and then the shallow water table I’ll use my 45amp on.

I read most of this thread and one thing came to mind. I have heard of shops installing a dedicated grounding rod for the table to help cut down on any noise interference. Might be worth looking into

Not sure if you have resolved your issue hopefully your have. But I had a terrible time as well with the copper plus electrodes. I called hypertherm and they told me you have to run the copper plus electrodes with higher pressure because the those electrodes are heavier and it takes more pressure to move the electrode to fire it. I think I’m running 80ish + psi on the machine. And 110-120 into the machine. After upping my pressure it fixed the issue. Also I have had issues when cutting cold rolled because of the oil that comes on cold rolled. I’ve had multiple misfire in the same spot with cold rolled and as soon as I clean of the oil not a problem.

that is interesting i use those electrodes all the time. what thickness are you cutting. i use them to cut .250 with a full 4x8 sheet i get 1500 pierces and approximately 4 hours of arc time. i do change them between sheets i have pushed it to about 1800 before a falure. when i researched them, they advertised them to keep material under .5 and arc cycles under 1 minute you can see double consumable life.

No!!! I have constant issues, have to restart the controller, Z messes up, cutting gets erratic, loses zero because had to restart. It loses it’s position, then loses work zero. I have lots of CNC equipment, but nothing as troubling as my Crossfire Pro. Tried different computers, tried different plasma cutters, the home limit switches were a waste of time and money, the THC was a waste of money, it works for a little while then ruins another piece of material. Different plasma cutters didn’t help, isolated electrical, tried every trick and nothing helps. I used it about 2 times when I got it and got frustrated and let it sit for about 6 months, used it again and thought it was working, then same crap happened again. Trying to use it again today and wasted more material. Running anything CNC from a computer is stupid, I’m about ready to throw away the whole controller and install my own offline controller. So no. I would never recommend this for anyone trying to use a Crossfire Pro for Professional use. I could have and should have built my own machine for about the third of the cost.

Man, sorry for the bad results. Sounds like you’ve tried some things to resolve. Have you tried working through the failure modes with Langmuuir Tech Support?