Hypertherm is pretty useless right now. I called a couple weeks ago about a wiring issue and he told me to google the service bulletin which I did but I had a couple questions I wanted clarified and his response to me was… I’m working remotely on my laptop and I can’t zoom in good enough to see what you’re asking.

OK then I guess your useless I’ll figure it out myself then and that was the end of that phone call.

Since I have read your thread ive been paying closer attention to the amount of misfires I have while cutting with my 45xp. When I would get misfires the “retainer cap of” light would flash very quickly indicating “consumables stuck” or something along those lines.

After playing with the torch head a bunch I ended up spraying just a little brake clean in the head and working the little plunger that lives in there back and forth. I was surprised to find it stiff and not much movement. I was able to get it freed up and moving a lot easier by hand. I haven’t had a chance to run it after I cleaned it up but am hopeful that it solves the minor misfire issue I have been having.

Might be worth it to check yours?

Are you talking about the safety switch that was sticky?

No, I mean the plunger in the center of the torch that the electrode pushes against. I feel like mine wasn’t moving freely enough causing the issue. We will see today!

There is no plunger in the duramax torch for a 45XP

I do not own a duramax torch, so I didn’t know that! Was just a shot in the dark trying to see if I could help him. Hopefully you can get your issue sorted out soon Directioneast.

My error code every time is an 030 code which is a stuck electrode. Today was another battle. I wasted 40 min atleast between misfires and then my X axis lead screw nut coming loose. That is two times that has come loose if I recall. Ended up ruing some parts. Tightened the lead nut up reset the file to cut what messed up, and again the location was off. So… I ran a new sheet over on the other side of table and it was ok. I managed to get a couple sheets cut with no misfires bf this issue. I had close to 8 misfires today, 5 in first hour (though they weren’t new). I would loooooove to get feedback from anyone using hypertherm that can get minimum 1500 pierces per consumables ( I know alot of variables there). Or… someone that can cut over 5hrs a day and not have a handful of misfires.

I like the PRO alot but so far this month has been hell week. I will be trying a new company next year and Im about to buy a new plasma bc Im beyond sick of hypertherm. I know everyone says they are the best, but this is an absolute joke. Way too unpredictable. I had better consistency when cutting on my CF as far as consumables. I will be trying pierce and cut at the book settings again as Iv tried bf, that is why I started changing that up some bc the consumable life was way shorter than normal.

Iv been dealing with this for almost 2 years so its not my first rodeo. However Im sure there are some things to try. I have 1/2 shop air line I have to install still. Also raising the rails up on the table so there is some distance work with between the water table. I also don’t change my water often so not sure if that would be effecting anything or not. But again its always the same error code with stuck electrode.

Is the code 030-0 or 030-1?

0-30 which is torch stuck open. nozzle and electrode are not touching. When I talked to hypertherm several times about it, they are aware of needing more dwell time on back to back pierces. I added the .5 sec after cut and with new consumables I was able to have better success, but still isn’t solving the issue.

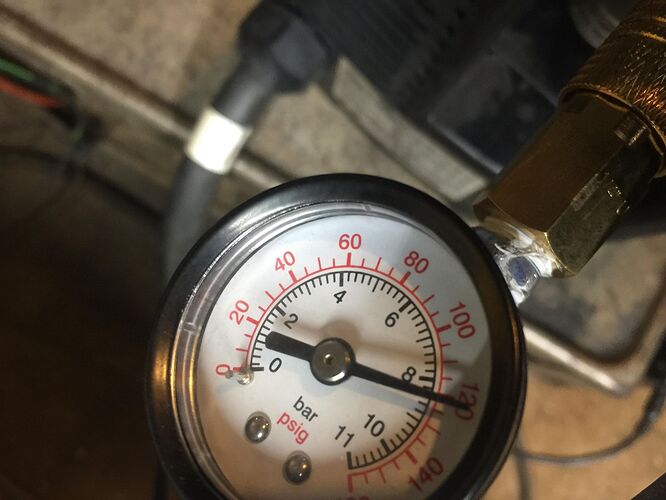

I have a regulator after filters and right bf the plasma. I keep it around 120 psi. My air compressor is just a 60g right now 90/150 off and on pressure switch. So on the low side I watch my gauge to make sure it doesn’t drop below 85psi which I often will pause cutting just to help that. However I just tired that yesterday and with full pressure I had a misfire. So I just don’t know if it is a pressure issue or maybe a volume issue, that is why Im going to install all 1/2 lines. With new consumables I have the best chance of no misfires for a good bit of the day, however I had less than 100 pierces on the last ones I put in and I was getting misfires, so again maybe a fluke there.

Iv just dealt with misfires and machine issue for way too long. I make it work but its heavily hindering my ability to grow. I rarely can go one day and cutting less than 3hrs with no issues. Its either a table issue or a plasma issue and sometimes both. Last two times I cut I had issues with both and ate up over an hour time. I could not imagine a shop running my hyp xp 65 all day and not changing the consumables every 1200-1500 pierces.

What I plan on doing when my next 100$ batch of consumables shows up is try using a set for each thickness of metal I cut and experiment with how long they will last that way. Also I was just piercing at .010 lower than the book calls for. I’ll reprogram these files and see how it goes at .200 vrs .190 pierce

What I find odd is I had longer consumable life when I used my CF and pierced and cut at .125 so essentially I was cutting at twice the recommended height.

I’m not at my shop this weekend but on Monday I’ll pull my consumables out and take a picture.They have cut 7 5’x10’ sheets so far with them and there still cutting fine. I’m not sure of the amount of pierces on them but I can look it up and get a pretty accurate number.

I’m running a 1.5 delay after cut not for misfire reasons but just in case reasons.

How old is your plasma cutter? How come you went with the 65?

It just really seems like your fighting two intermitting battles with both your plasma cutter and the table.

Do you have the hand torch for the 65 as well? Are you able to mount that on to see how it acts with that torch mounted?

Id appreciate some pics. On one of my products I have about 800 pierces and 4500 inches of cut. I like to get around 3 sets of those products so about 2400 pierces and 13500 inches of cut out of same consumables if possible. Now about half of that is 11g aka 1/8 mild steel, other half is 3/16. I do cut some 1/4 also but its not a large amount. It takes about 10 or more sheets of 12x24 to create my product. I can’t do a 2x2’ layout simply bc of misfires and program freezes. Also much easier to edit the files when they are smaller scale. Again just another hindering situation for growth.

My 65 is less than 6 months old. I got it mainly for production increase. I have 2 months of orders and If Iv spending 3 days cutting Im fabbing for 3 days. The 65 has really helped with time. Even with all the problems it gives me or machine issues in past and present, CF vs PRO. Im still getting faster production now. But I just know I can get better consistency outta both. Also my 45xp misfired alot too, when I first got my 65 I was really impressed as the air valve in it is much smoother and quiter than the 45xp. I thought for sure it was going to misfire less. For a while it did but now Im back to the randomness. I cut a ton of small holes so I know that is part of the problem. It rarely misfires after longer cuts, though sometimes it has.

I have the machine torch and hand torch. I don’t want to mess with the wiring in the hand torch bc I use it for shearing some sheets. On my 45xp I had the 15* hand torch and wired it up to connect to the cnc port on back. Also there is about a .060 gap where retaining and machine torch meet. Like it won’t screw on all the way. I thought that was rather strange but its the right cap 220854. I use the better electrodes 220777 called the copper plus.

What is strange is the cut quality is still good once I get misfires, so its not always just worn out consumables, I look at them and they seem fine too. But, they won’t be consistent with firing. So when I change them out I have better odds, but not always. Iv had packs of consumables that I swore were defective thats how many issues they gave me. With my old filtration I started changing it alot, now with new filtration I shouldn’t have to worry as much. I am wondering if the 3/8 air line I have might be an issue. I have to find time to hook up the 1/2 line. Also am debating on an 80g compressor or I have a nice atlas copco rotary screw compressor at my other shop that is 2hrs away. Its a nice quite compressor with built in cooler, but its 60g, so be kicking on alot still.

Maybe the stuck open code is not enough air, though I’v had misfires with plenty of air, but…I do notice most the misfires come right after compressor kicks on. My pressure switch is low side 90psi. My machine says min 85psi. However with new consumables Iv gone over 1k pierces and no misfires so Im not sure if my low pressure theory is on point.

The Hypertherm 220845 is a 80 AMP bevel nozzle retaining cap. I would be using a 220854 and a 220817 shield

Im sorry it is the 220854 its actually used on the 45, 65, 85 and maybe even higher. Yes that is the shield I use as well. I also use the 65 nozzles which I call tips. Just got a new swirl ring too, which even when I did that a while ago made no difference.

When I first got my machine torch for the 45xp the retaining cap wouldn’t screw all the way on either but it was worse then a .060 gap so I went back to praxair and they gave me a new one and it screwed right on and bottomed out easily.

That is something to look at though cause that could be causing your issues.

Do you happen to have a pressure gauge after your filtration to see what you’re getting at the plasma? Have you done a air test with your plasma?

You do have quite the filtration system set up and with that and the 3/8 lines could be adding up to a big enough loss.

I have a small screw compressor only 7.5hp and 60g but it has 25cfm at 150psi and 3/4" lines running in my shop.

Well, I had same inconsistent issues when using the 45 also. Now with the 65 and the retaining cap, bad pic but yeah it won’t touch the white part of the handle. Just seems prone to getting stuff in there.

I have a really nice pressure gauge right after filtration and then about a 3ft hose that goes into another cheap gauge right at machine. The nice gauge that is on my filtration is at 120. So when my compressor is on I have a video showing the gauge at 110 and cycles down to 100. When I have full air Im running around 120 and pulls around 110.

Yeah the new filtration is all 1/2 fittings but I had to dumb em down to 3/8 and I do believe the port going into the plasma is 1/4. Could be wrong, but yes I wanted to try the bigger lines.

I know alot of my problem is the amount of pierces per sheet. In just a 12x24" sheet I have 60-100 pierces. Iv reprogrammed the files to not cut so many small holes in a row, I also jump around to let the machine catch up. I could add more pierce delay I suppose. I really hate to add more than .5 seconds on after cut but I could try that. I just don’t have any other good leads on what to do. Some days are ok some are bad. Rarely a great day cutting. I got new consumables again so gonna try some other settings and maybe use one set on my 1/8, 3/16, 1/4" and see if I can’t get some results that way too. Sometimes I’ll take used set of consumables and use them on sheets that have long cuts and less pierces. So Im not wasting my new consumables on long cuts, as I need them for holes.

Have you done on air test on the plasma cutter itself to see what the machine is seeing for psi?

If you did add more time to delay after cut and it helped spending the extra minute or two on the program you cut would be better then the 20 mins you spend screwing around.

I don’t know how close you are to a welding supply place but a new retaining cap wouldn’t be a bad idea.

I have done the air test on both plasmas I do believe. I’ll give it a double check today. However I don’t recall the machine allowing up to 135psi inlet on the digital readout. I will look into that. But… again Iv gotten more life outta consumables without using the THC it seems. Looking back at all my log notes Iv gone longer stretches. With the PRO table using the same plasma 65xp Iv gotten about 1200 pierces on my one set which was the most I’v gotten with this setup. So if its an “air” issue, I just dont see why its so random. I have over 5 retaining caps, I know I’v atleast tried two of them, same results.

Another concern I brought up bf was Plunge rate. The rate at which torch goes from pierce height to cut height. I have mine set to 50imp. My average pierce delay settings are .4 and .5 with .5 being for 3/16. I will sometimes bump it up through FC maybe 30% as time goes by on used consumables. So if plunge is too slow it would essentially create unnecessary resistance as the metal is prolly already blown through, but… that would only happen with proper pierce delay. If pierce delay is too short than plunge rate might not even factor as much. Basically it seems plunge rate goes hand in hand with pierce delay. So when you get over 1k pierces, seems like every little bit is factoring in. What I don’t get is, my consumables look ok. I can rarely wear a hole into the electrode like I use to. Now the hafernim just splats out and creates a little lip on the tip, which doesn’t seem right to me.

Also on my machine, I have it set to continuous cutting, so if say the arc went off the sheet, it would stay lit. However hyperthem book says this will shorten consumable life. Im guessing this is only when that happens, meaning arc is firing without metal under it, in my case very rare.

Just got off phone with tech support. Said plunge rate is not an issue. Continuous cut only effects you if you run off sheet. Said the 0-30 issues haunt them, which I know for sure they do. Said clean nozzle and electrodes a little more. Pressure really isn’t the issue as I’d be getting error codes if it were.

I don’t understand why FC will detect a non pilot start sometimes and other times it won’t.

Also I was reading my settings wrong, thought shielded vs unshielded meant running air vs gas. Well that isn’t the case. Howver, I have ran all my programs at .150 pierce and .06 cut and iv tried .200 pierce and .08 cut and lastly I have done .170 pierce and .07 cut. On the last settings there I had gotten the most cuts with no misfires and quality is good. I will try book settings again also.