I cant really help you with you issue at all it seems strange.

I have a original crossfire xl that I picked up used quite a while ago with a 45xp and hand torch on it and I use that often to make small parts when I’m building a suspension from scratch for trial and error parts and I dont blow through consumables like that at all and your filtration system is way better then mine. I also have a 5’x10’ table that I use for production parts with a different 45xp and machine torch and same thing you have better filtration but I dont blow through consumables like that. I cut 3 .188 5x10 sheets today so probably 5 hours or so of cutting I’m not 100% on time but that was with consumables that already have quite a bit of cut time on them with no misfires and lots of back to back pierces.

I use mach3 for the crossfire and command and cut for my big table

thanks, yes that is the type of feedback I was looking for. I just got to be missing something, been way to long dealing with this. I cut 12x24 sheets bc of misfires mainly. Can’t risk going larger bc of wasting material and time. I atleast have a base to go off of bc I know what I’v expected and gotten out of them bf. But now its different, can’t seem to have anything good happen. Iv had issues with the PRO table and FC which most are fixed, not all but I like the machine. I have more plasma issues than machine issues right now. I just spend about $500 on filtration and all new air lines. Yet to hook up the line, but man I was so bummed when I got a misfire today. All genuine consumables, electrodes are $10 a piece. Swirl ring is fine, have changed them bf, checked tightness, pressures, pierce delays, cut height, pierce height etc. All by the book and a little tweaking on some stuff. compressor sux but its a 60g and flows 11 cfm at 90psi.

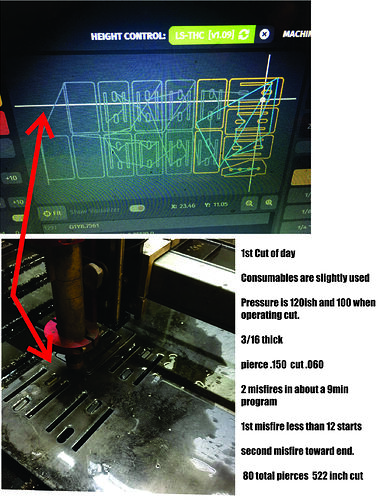

Went today to cut a couple things. Here is a layout I made showing misfires. Had two on first sheet of day. You can see in the last pic with consumables, they don’t even look bad. You can see it still cuts decent as this was the last part on the sheet that gave me 2 misfires. This was right off the bat today, first sheet of day. Just used these consumables yesterday for bit.

I can honestly only think of having a misfire once but I’m pretty sure that was all me by not hooking up the right airline and having too much moisture from the compressor and well used consumables.

I’m not familiar with cf pro or fire control at all on how its wired or works but are you able to disable the thc and just run it at a set height to see if it runs through the program without misfiring?

I’m also running the same set up same psi same pierce and cut height on my big table and set the original cf at .060 for both obviously with the lack of thc lol

Try adding a .5 second in sheetcam for “pause at the end of cut”

As for the pierce delay, I start at adding ~90% to the book settings and adjust from there. It is usually plenty of time to pierce, which I feel is better than the torch moving prior to completing the pierce.

This is what works for me with the 45xp and so far I’ve been able to get over 1000 pierces out of a set of consumables and haven’t had any misfires.

I ran same setup for well over a year with no THC, hypertherm 30xp, 45 xp and 65 xp. I always would set the torch using the larger shim which is .125 thick I believe, so essentially I was cutting at double the recommended height. I would get misfires but not as often and was able really stretch the use of my consumables. One set of my product uses alot of sheets, but lets say I pierce about 900 times and cut 4400 inches per set of product. I was getting about 3 sets before I would change consumables. thats over 2700 pierces and 13,200 inches of cut. Right now Im getting misfires more often with the THC.

Yah I thought about the pause at end of cut, but just never did it. I honestly think the PRO with THC fires faster than the CF. I was worried it would make cut times longer, but its actually a very rapid setup, so perhaps that is too fast for the Hypertherm. Hypertherm techs have told me they are working on that issue. However I don’t understand how they can sell 50,000 units of just the 85xp, be the best plasma company around and yet small shop me can’t even use it for 2hrs without misfires.

I run over 10 different work files a day when cutting. I have tons more cut files I’ll have to reprogram. I guess I’ll go for it and see if it helps.

Im running a 45xp with a t45v torch and I’d say I put in about 5-10 hrs per week cutting junk to sell. I own a PRO, coming from an OG crossfire. I didn’t have much experience with the 45xp on my OG crossfire as I upgraded my plasma from a hypertherm pm30 (non xp) at the same time as my table.

I do notice I have more missfires with my PRO than my OG/Hypertherm 30 combo, but not to an extent that drives me bananas. I’d say in a 32"x48" sheet I might have 2 or 3 total. If I can give you any more information that might help you about my setup feel free to ask.

That is helpful, more feedback on this the better. Per my numbers above on the OG CFire I was getting atleast 1500 k pierces bf I would expect misfires and then I could push it to about 2800 pierces. Right now Im at a third of that with the PRO, so if I can’t get to the bottom of it, my costs went to about 100$ a week in consumables or about 3x’s my normal costs. Hoping the pro would add life to my consumables Im just baffled.

I have tired both cut heights per hypertherm manual. One is for shielded and one for unshielded. .150 pierce and .06 cut seems to work better. Im now going to add more pierce delay, .5 sec after cut and then try a .180 pierce and .07 cut. So I’d be splitting the difference from the .200 pierce and .08 cut hypertherm suggests. Again I don’t think the pierce and cut are necessarily killing me bc again I was cutting at double the suggested height on the OG Crossfire and getting way more life out of them.

The new filtration hasn’t helped one bit so far. Im going to upgrade all my lines to 1/2 soon.

I also thought the misfires got worse during the later part of day, so maybe hotter air. But I’v had misfires on the very first sheet on two different occasions last week. Im talking 10 pierces in and a misfire. It woudn’t be so bad if 1. the run from here was different in FControl, which they are changing up and 2. if FC would detect the misfire and auto restart position it (rarely catches it but when it does I really liked that feature) .

One positive thing I really like about FC is the pause feature. It has super fast response to pausing. I also like the jog features.

Here is another thing Iv noticed. I use the better electrodes 220777 which run $45-50 for 5. Per the photo here is what I use pushed them to the point of changing them electrode on LEFT. Now I can’t for the life of me get an actual hole in the electrode on right. The hafnium metal inside wants to splatter out of the electrode and create almost a lip on most of them. So the one on the right became a very problematic electrode, misfired all the time, wasn’t that old. Now if I took that electrode and cut with a hand torch it would be fine. For the most part the cuts are still pretty good with worn electrodes, they just end up misfiring alot.

Today was an pretty good day. Took it a little slow however. I ran all my new files with .5 sec delay after cut, I also paused the runs sometimes if compressor seemed to run too long. Overall I had one hiccup today where machine got off coordinates (only happened one other time so far in a month). My lead screw spring carrier went loose. I was able to cut everything here and some in about 3hrs. Close to 800 pierces and probably close to 4500 inches of cut on new consumables. NO MISFIRES today!

I think the .5 delay after cut really helped. Tweaked my pierce and cut heights too. What you see here I normally can get another 2 loads of using the same consumables. So… I’ll know more later this week how well it goes.

What is your pierce and cut height at now?

Today I went .180 pierce and .07 cut. book says .200 pierce and .08 cut for 65 amp. I can get very little to almost no dross on the 1/8. I get dross on most of the 3/16 but it easily comes off. Dep on direction of torch cut it will sometimes get no dross on parts of the parts. Im able to scrape and clean up alot of my parts during cutting, so this actually saves me alot of time. Back when i used he CF I had alot of dross bc I cut too high, do to warped sheets etc. Im cutting 62amps with thicker stuff and 52 amps with the 1/8"

Well hopefully those couple changes sort out your issues I know it can be so annoying plus the consumable costs add up they don’t give them away.

Cutting 1/8" at 45 amps and 140ipm i get pretty much zero dross. 3/16’s is pretty good too but i really struggle with 1/4 though can’t seem to get it dialed in it cuts fine just a lot of dross but 3/8 cuts good.

Are you using the PRO with THC? Using hypertherm xp45? I use to cut 1/4" with the 45xp at 50ipm with the CF. Now with the PRO, THC and 65xp plasma Im cutting at usually 80ipm and 63 amps. I get dross on alot of the parts but it comes off very easily. I don’t like running top speed bc of arc bend

As you know they make all kinds of grade steel. I use alot of A36 they call it. So maybe your 1/4 is a diff grade.

I make alot of money each month with my business, but when doing volume, any additional costs adds up. So when you add even $5 in cost to my product that adds up. For me I usually stretch $80 in electrodes and tips for a few weeks, lately its been about a week and half. Im hoping to be able to have more cut days like I just did. I will be posting an update.

No I don’t have a pro I use a 5x10 tracker table for production parts I’ve developed and sell and I picked up a original crossfire used for $500 bucks Canadian so basically $20 bucks US lol.

I work in the offroad world so anything from stock jeeps or trucks to full tube chassis buggies.

I’ve made a lot of truss kits for people that want to upgrade there axles to dana 60’s or 14 bolts but keep there stock suspension components so more of a diy kit if they can weld to all out kits where its all cut out and start from scratch.

The crossfire works good for developing because I just wheel it over and make parts on the laptop cut them out of 1/8 and modify it till I get something I like and works.

Very cool, I make my living in the hotrod world doing all fabrication right now. Everything I do is proprietary. I did over 100k in sales with my first crossfire. Eventually swapped out the top portion with another unit and went to the XL. Soon as I did that they offered the PRO. I was going to try the Wright 2x4 they make but then I just went with the PRO. I think if they can nail an industrial version I’d be all over it. I really like the size. I don’t really need a large table, but a little bigger would be nice too. Im going to make new stansion plates to raise the rails up on my machine. I think they should do that for an industrial version and make the water table a tad deeper. Offroad and jeep stuff seems like a big market.

I didn’t need a 5x10 table either but I found a deal and I have a 60’x100’ shop so I had the room for it and I jumped on it and made my investment back in no time but I would be happy with a 4x4 table.

No offence if there’s any jeep guys here but they’re fanatics about jeeps and they always want something new for them.I make a bunch of bolt on and weld on stuff that sells really quick like skid plates, motor mounts,tcase mounts rear end swap kits,body armour,flat fenders, rocker guards and some other stuff.

Then all the custom all out custom buggy stuff where they drop off there drivetrain and say build me a tube chassis.

It definitely keeps me busier then I ever expected it to.

oh ya plenty of work out there. Its def a blessing to have alot of work right now. I have constant 2 month wait list of orders. I have tons of new product to launch just not time to do it right now. Cool to meet someone on here that does very similar stuff.

Ruff day again. Z axis gave me trouble a couple times. Right off the bat it wasn’t touching metal, so stopped program and reopened it. Then later in day it fired a couple inches away from metal. So stopped program again, axis and bearings felt gunked up. So cleaned it all etc. FC froze on me today also. Had the Z axis not touch the plate one other time, had to stop program. Once I do that, I cycle the axis all way down to make sure is gonna touch etc bf I restart. Overall not a huuuuge deal but mix in a day with machine and plasma issues and it just sucks. I literally can’t cut for 2hrs most the time without problems. Most I deal with regularly, so not just crying about it.

I had a good cut day a couple days ago. No misfires. Today was on track for that but then I had 3 misfires on one 12x24 sheet and got pissed. Put new consumables in. So that got me a kit and a half of my product, better than what I was doing but that means I’d go through 2 electrodes and 2 tips in 3 days of cutting if I cut for about 3hrs a day (thats not all table time). I like to get more done but at this rate its too much of a fight during the day. Im getting hung up for atleast 20 min a day with these issues.

On my new consumables I had less than 100 pierces then got about 5 misfires. I finally checked the retainer and nozzle, fiddled with them a tad and finally got it to finish the last few cuts. So I dunno if that was just a fluke or not. That capped off my day as the struggle is real.

These are the consumables I used the other day and had about 1200 pierces on them. Misfired 3 times one small sheet. So out they went.

Calling Hypertherm tomo and see if I can’t accomplish something. I got one email from them, sent them pics and never heard back.